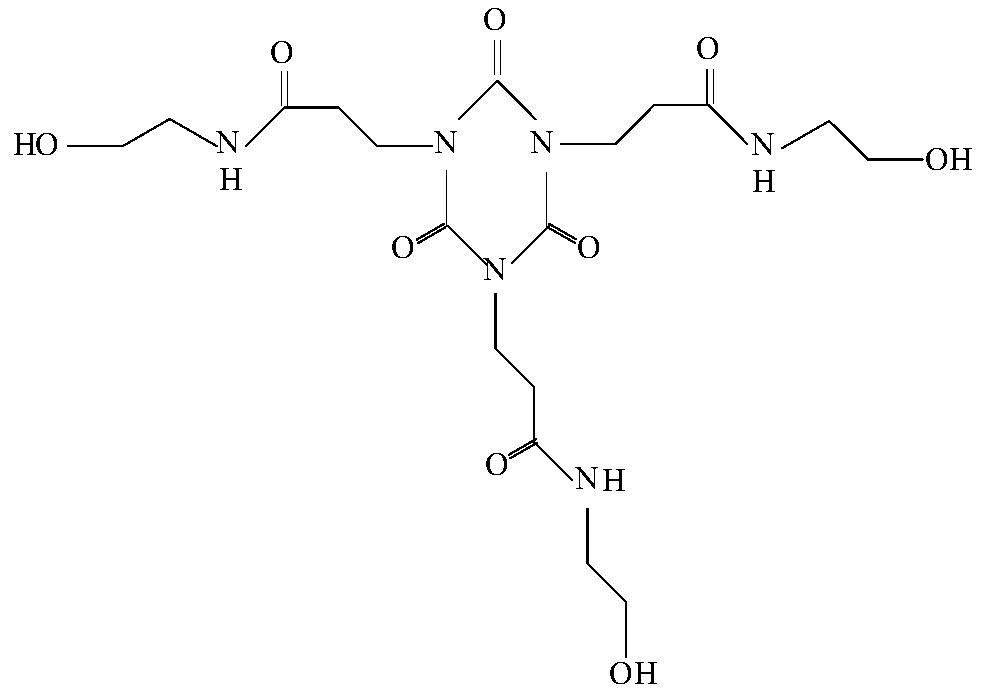

Preparation method of n,n,n-tris(n'-hydroxyethyl-3'-propionic acid amido)-1,3,5-triazine

A propionate amide and hydroxyethyl technology, applied in the direction of organic chemistry, to achieve the effects of less environmental pollution, high product yield, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

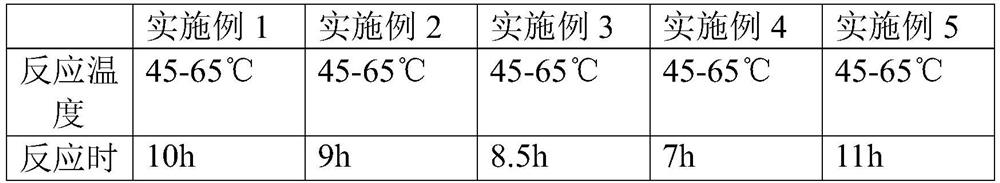

Embodiment 1

[0015] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 30 g of methanol and 38.71 g of N,N,N-tris(3'-propionic acid methyl)-1,3,5 - Triazine, 18.3g monoethanolamine, 0.5g potassium p-toluenesulfonate, start the stirrer, when the temperature rises to 45-65°C, start timing, and the reaction time is 10h. After the reaction, cool down to 3-5°C for crystallization, filter and dry to obtain white powdery solid N,N,N-tris(N'-hydroxyethyl-3'-propionic acid amido)-1,3 , 5-triazine product, the melting point is 99-102°C, and the yield of the product reaches 96.04%.

Embodiment 2

[0017] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser, and a thermometer, 70 g of isopropanol and 38.71 g of N,N,N-tris(3'-propionic acid methyl)-1,3 , 5-triazine, 24.4g monoethanolamine, 1.5g potassium p-dodecylbenzenesulfonate, start the stirrer, when the temperature rises to 45-65°C, start timing, and the reaction time is 9h. After the reaction, cool down to 3-5°C for crystallization, filter and dry to obtain white powdery solid N,N,N-tris(N'-hydroxyethyl-3'-propionic acid amido)-1,3 , 5-triazine product, the melting point is 99-102°C, and the yield of the product reaches 96.34%.

Embodiment 3

[0019] In a four-necked reaction flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 50 g of ethanol and 38.71 g of N,N,N-tris(3'-propionic acid methyl)-1,3,5 - Triazine, 20.2g monoethanolamine, 1.5g potassium p-toluenesulfonate, start the stirrer, when the temperature rises to 45-65°C, start timing, and the reaction time is 8.5h. After the reaction, cool down to 3-5°C for crystallization, filter and dry to obtain white powdery solid N,N,N-tris(N'-hydroxyethyl-3'-propionic acid amido)-1,3 , 5-triazine product, the melting point is 99-102°C, and the yield of the product reaches 97.88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com