Calcium removal system and method for ion exchange regenerated sewage

A sewage and separation technology, applied in the field of decalcification system of separation and regeneration sewage, can solve the problems of unsuitable sewage treatment, affecting the normal operation of production, and low decalcification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

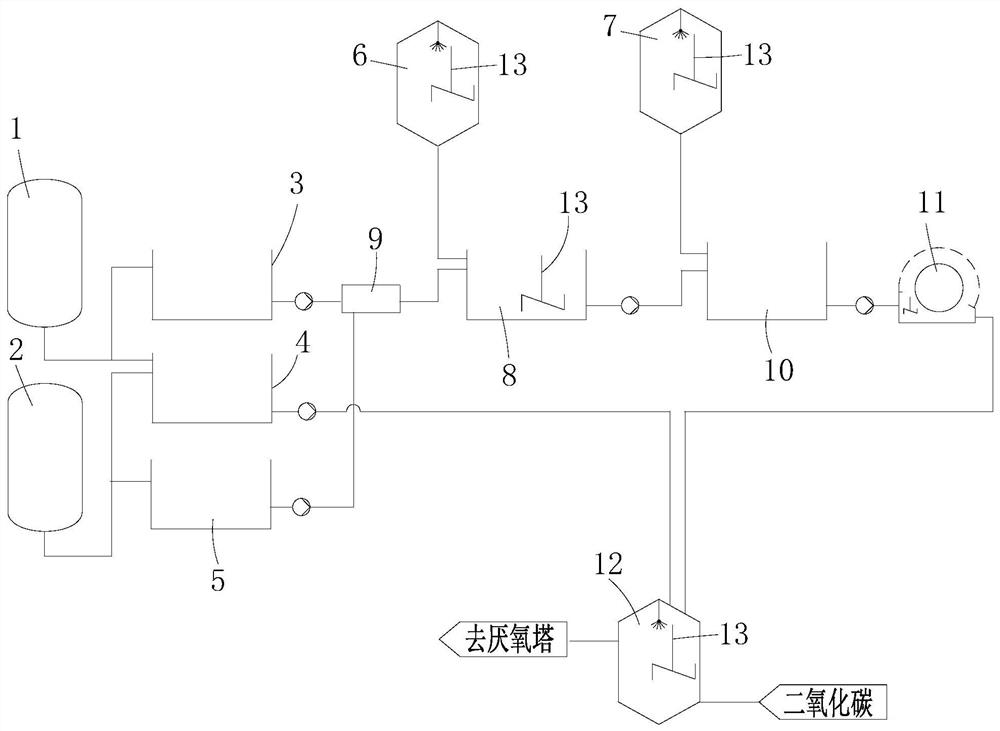

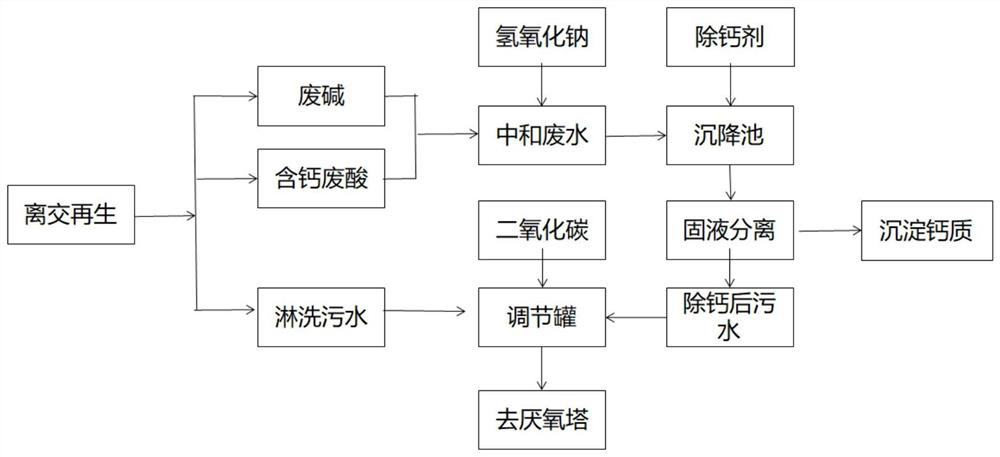

Method used

Image

Examples

Embodiment 1

[0055] Taking the separation of xylose mother liquor as an example, the calcium ion content of the material before separation is 1800ppm, and the calcium ion content is controlled at 20ppm after separation. The positive column regeneration consumes 12m³ of dilute acid (4wt% hydrochloric acid) per time, and the total sewage generated for one regeneration is 42m³; Column regeneration consumes 8m³ of dilute alkali (4wt% sodium hydroxide) per time, and produces 40m³ of sewage once regeneration, and the calcium ion concentration of mixed sewage reaches 1000ppm.

[0056] In the first step, when the Lijiaoyang column 1 is regenerated, the first 12m³ of sewage (calcium-containing waste acid) is discharged into the waste acid buffer pool 3 (in order to recover completely, the recovery time can be slightly extended), and the rest of the sewage (calcium-free) is rinsed. Switch to rinse sewage buffer tank 4.

[0057] In the second step, when the detached negative column 2 is regenerated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com