Edible salt refining production equipment

A technology for production equipment and edible salt, applied in the direction of alkali metal chloride, energy input, etc., which can solve the problems of prolonged salt precipitation period and no salt field, and achieve the effect of preventing rewetting and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

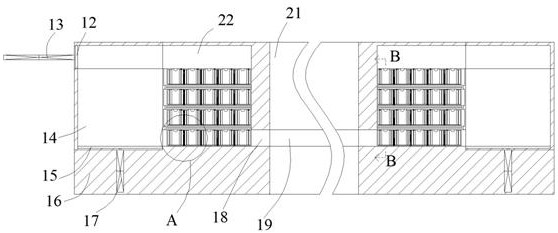

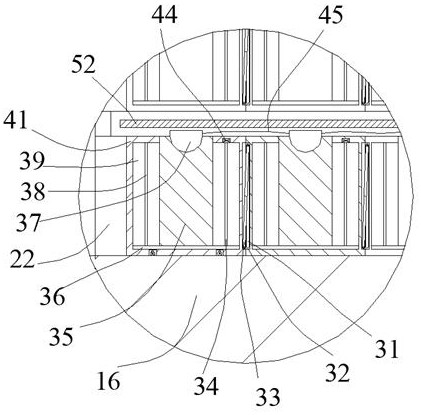

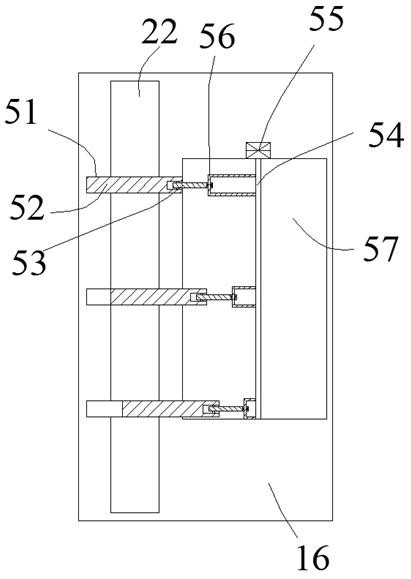

[0023]Such asFigure 1 - Figure 6As shown, the present invention will be described in detail, which is convenient, and now, the orientation of the following statements are as follows: The front and back and solapping direction of the followingfigure 1 According to the upper and lower left and so on the projection relationship of the projection relationship, an edible salt refining production apparatus of the present invention includes a casing 16, and an inner cavity 21 is provided in the casing 16, and the inner cavity 21 end wall is connected. The connection slip groove 19 is provided with a loading inner cavity 14 in which the mounting inner cavity 14 is connected, and the attachment chamber 22 and the connection chute 19 are connected. Connection is provided with passage through the hole 18, and an top-out cylinder 17 is provided in the lower end wall of the loading inner cavity 14, and a push plate 15 is provided with a push plate 15 and the top plate 15 and the top outlet. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com