Reinforcing structure of loom battening device and water-spray type loom comprising the same

A technology for strengthening structures and looms, applied to looms, metal processing equipment, textiles, etc., to achieve the effects of firm structure, reduced vibration, and ensured operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] [definition of terms]

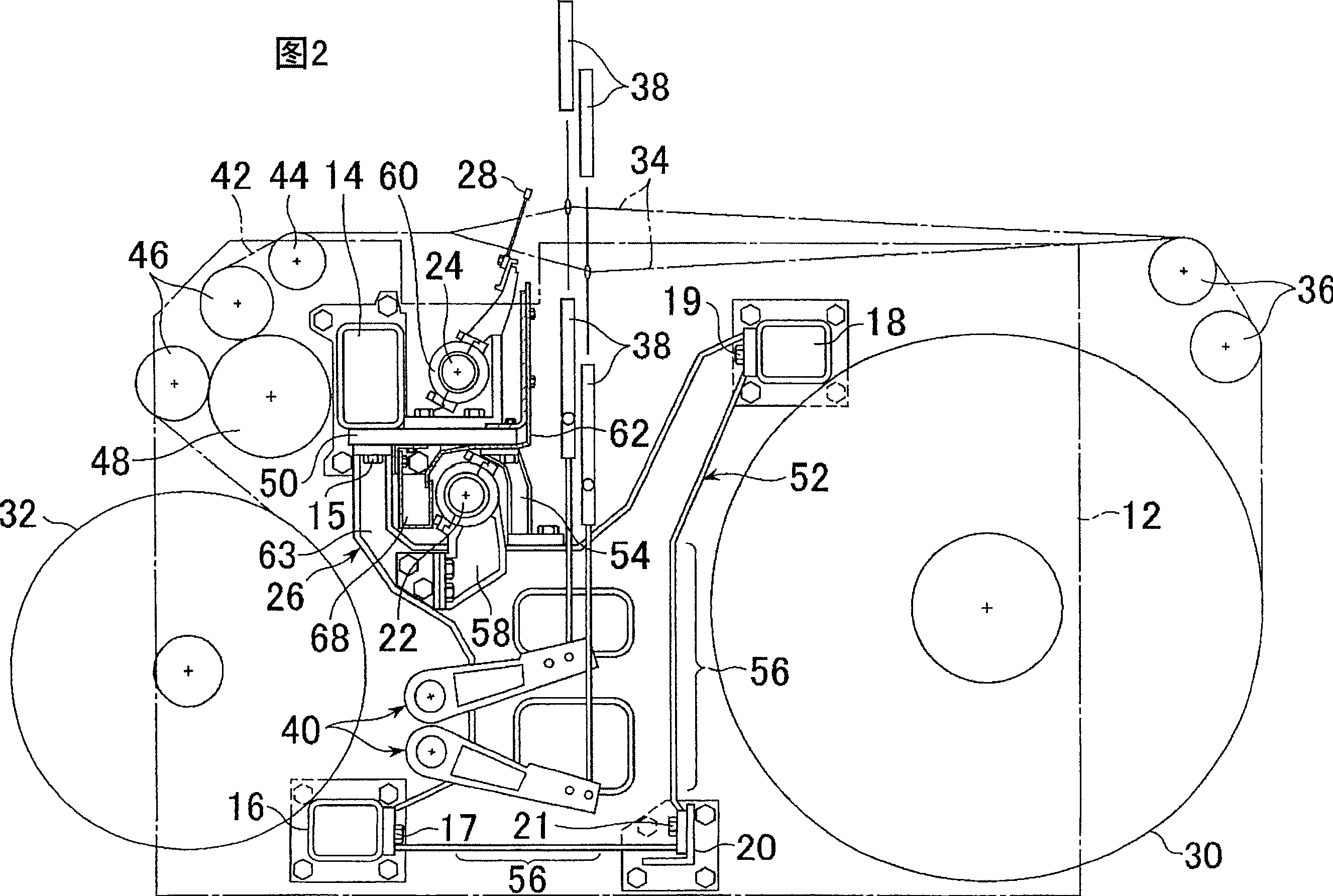

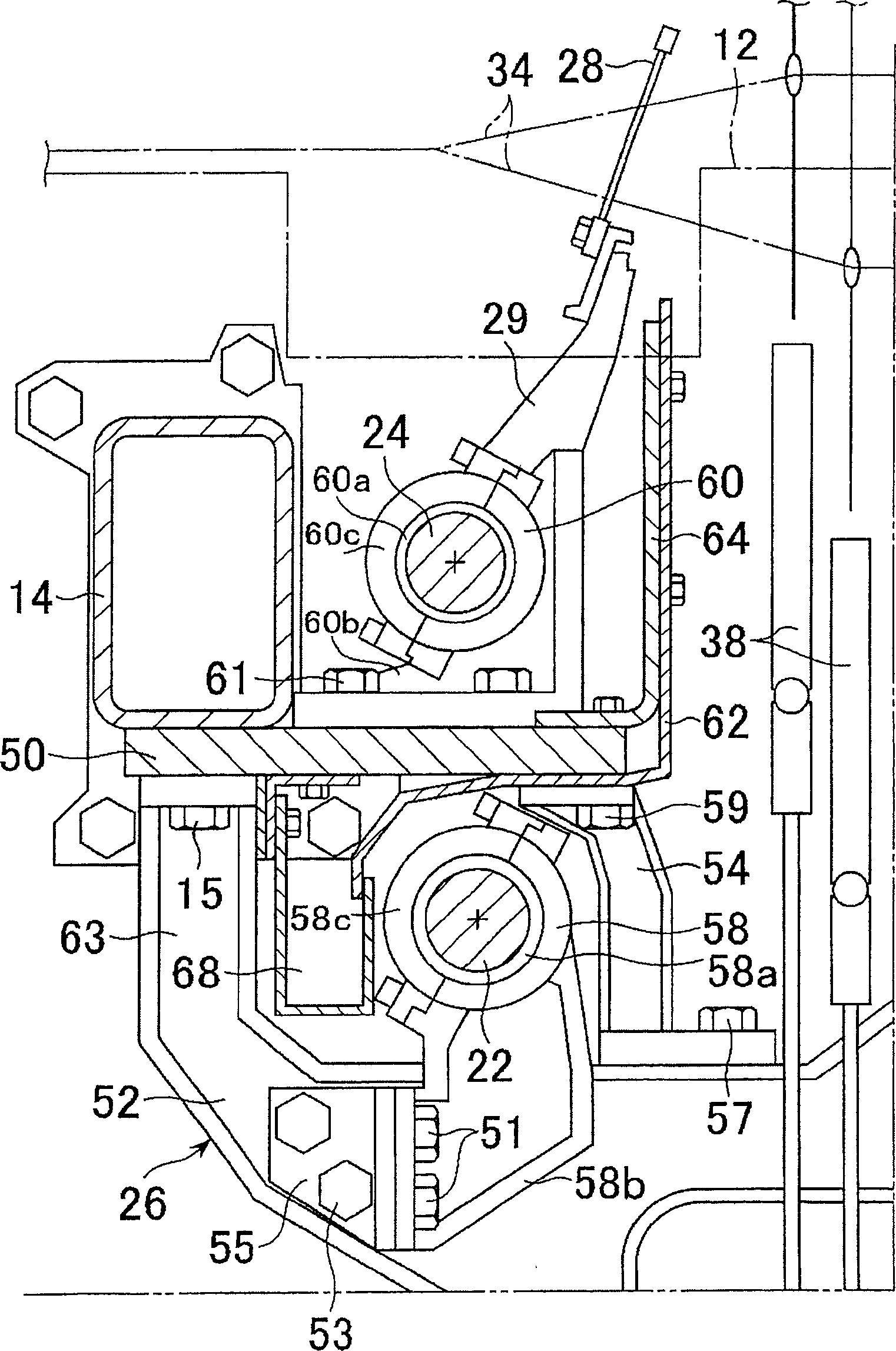

[0048] In the present invention, the weaving direction is referred to as the left-right direction, the warp feeding direction is referred to as the front-rear direction, the downstream side of the warp moving direction is referred to as the front side, the upstream side is referred to as the rear side, and the moving direction of the heald frames is referred to as called the up-down direction.

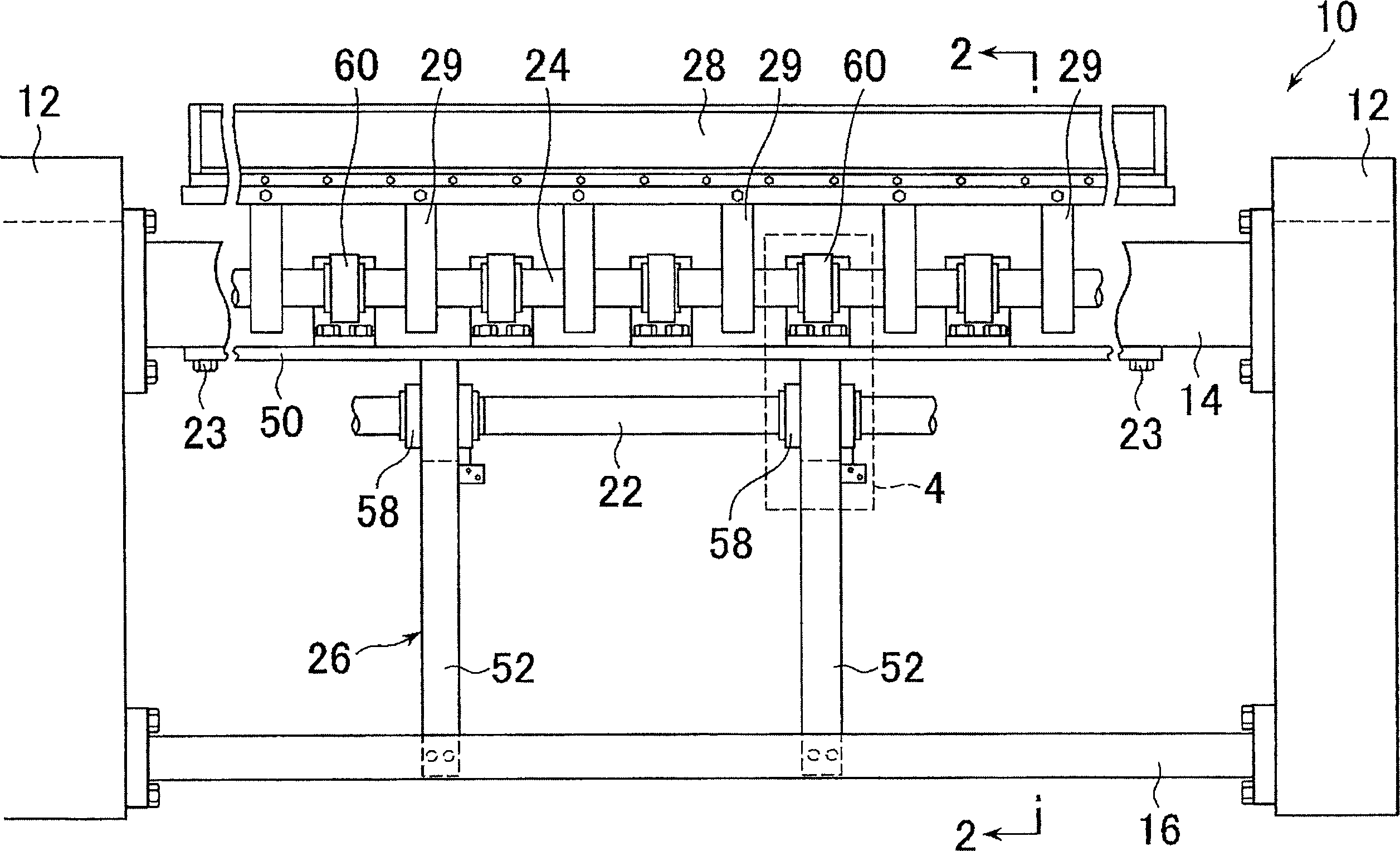

[0049] refer to Figure 1 to Figure 5 , the water jet loom 10 comprises a pair of loom frames 12,12 spaced apart in the left-right direction, extending to the left-right direction between the loom frames 12,12 and connecting the two loom frames 12,12's first to fourth struts 14,16,18,20.

[0050] The 1st, the 2nd, the 3rd and the 4th strut 14,16,18 and 20 connect the two weaving cloths at the front side upper part, the front side lower part, the rear side upper part and the rear side lower part of the two loom frames 12 respectively. machine rack 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com