Classification garbage can with automatic bag breaking and classified throwing functions

A garbage bin and bag breaking technology, which is applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of not having the separation operation of garbage bags and garbage, unsanitary, and increasing the workload of work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

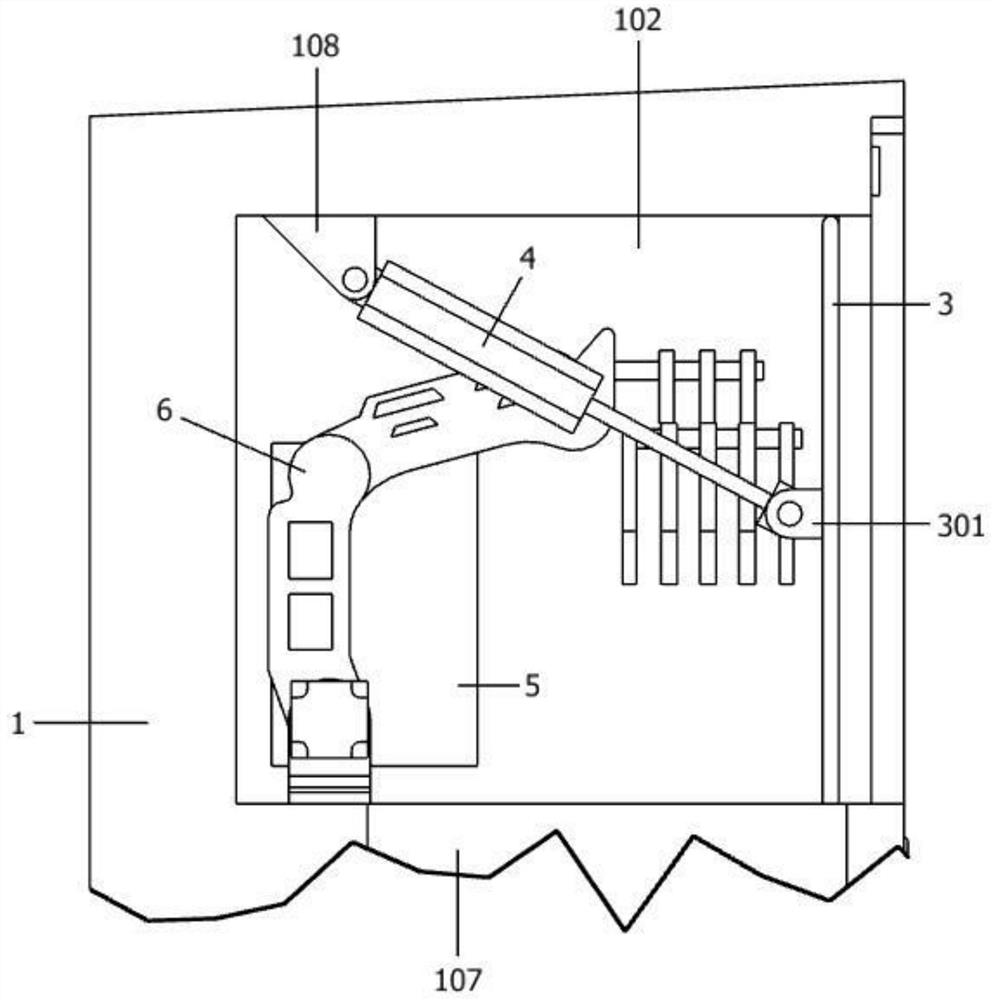

[0033] as attached figure 1 to attach Figure 7 Shown:

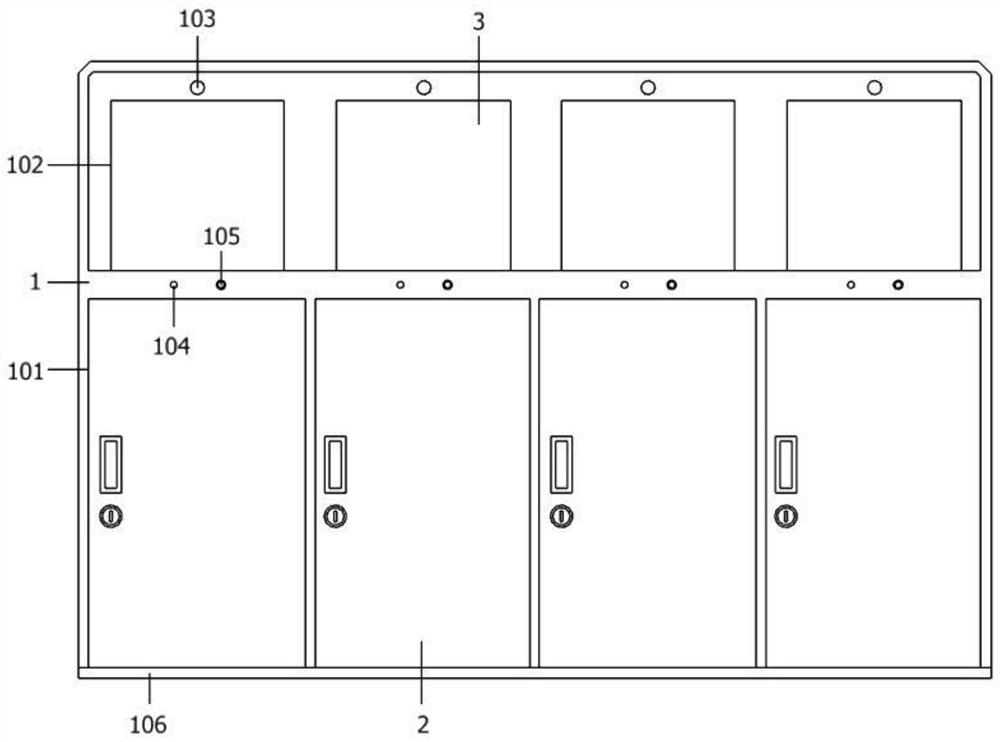

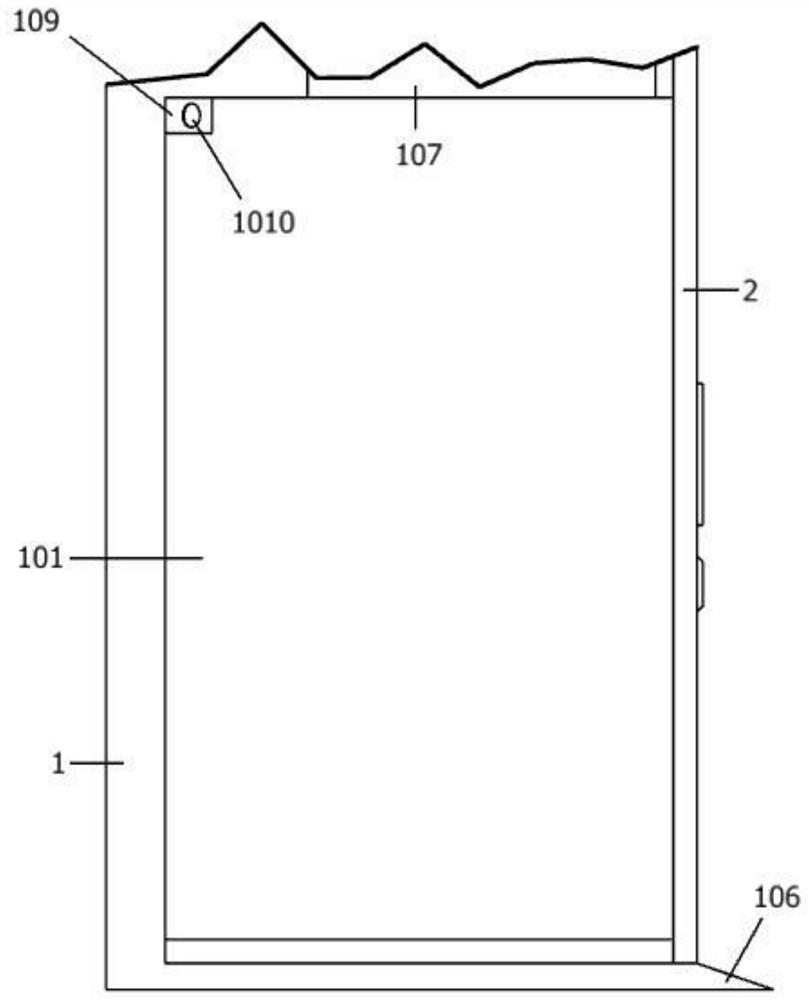

[0034] The present invention provides a sorting garbage bin with the function of automatically breaking bags, sorting and putting in, comprising: a garbage bin 1, the garbage bin 1 includes a garbage bin temporary placement opening 101, a garbage insertion opening 102, a reminder light 103, and a human body infrared sensor probe 104 , button 105, connecting seat A108 and loudspeaker 1014, the lower half of the dustbin 1 is evenly distributed from left to right, and there are four temporary placement openings 101 for the dustbin, and the temporary placement openings 101 for the four dustbins all pass through the front end of the dustbin 1 On the front, the front side of the garbage bin 1 is uniformly distributed from left to right and has four garbage delivery openings 102, and the four garbage delivery openings 102 correspond to the positions of the temporary storage openings 101 of the four garbage cans respectively, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com