Triangular-section arc-shaped composite truss and preparation method thereof

A composite material and cross-section technology, which is applied to fuselage frames, space navigation equipment, space navigation equipment, etc., can solve problems such as the inability to form arc-shaped curved composite material truss structures, many overlapping parts of limbs and tubes, and insufficient geometric accuracy. Achieve the effect of good light weight, high rigidity of the overall structure and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

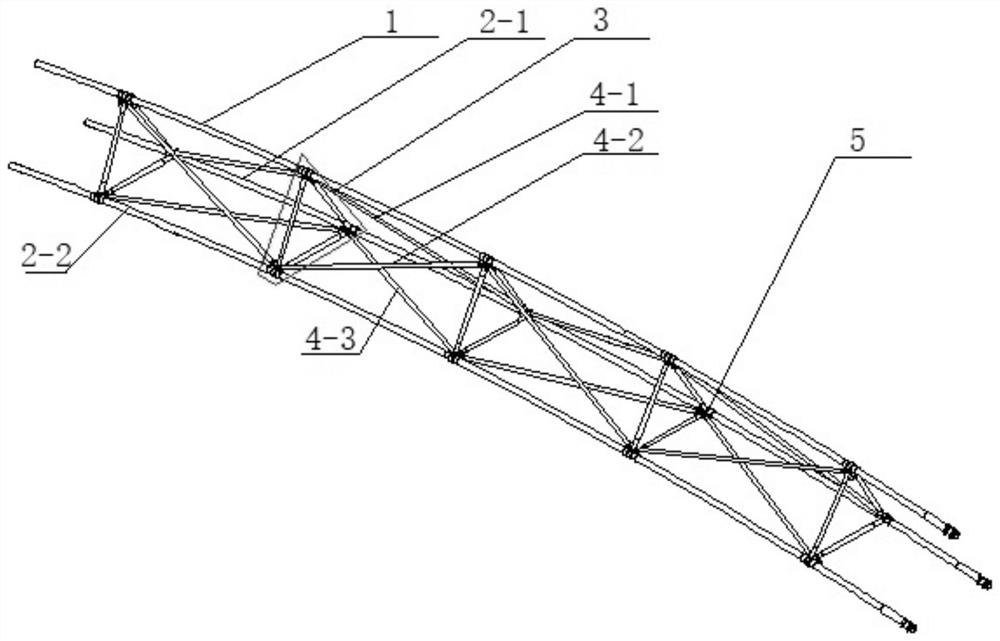

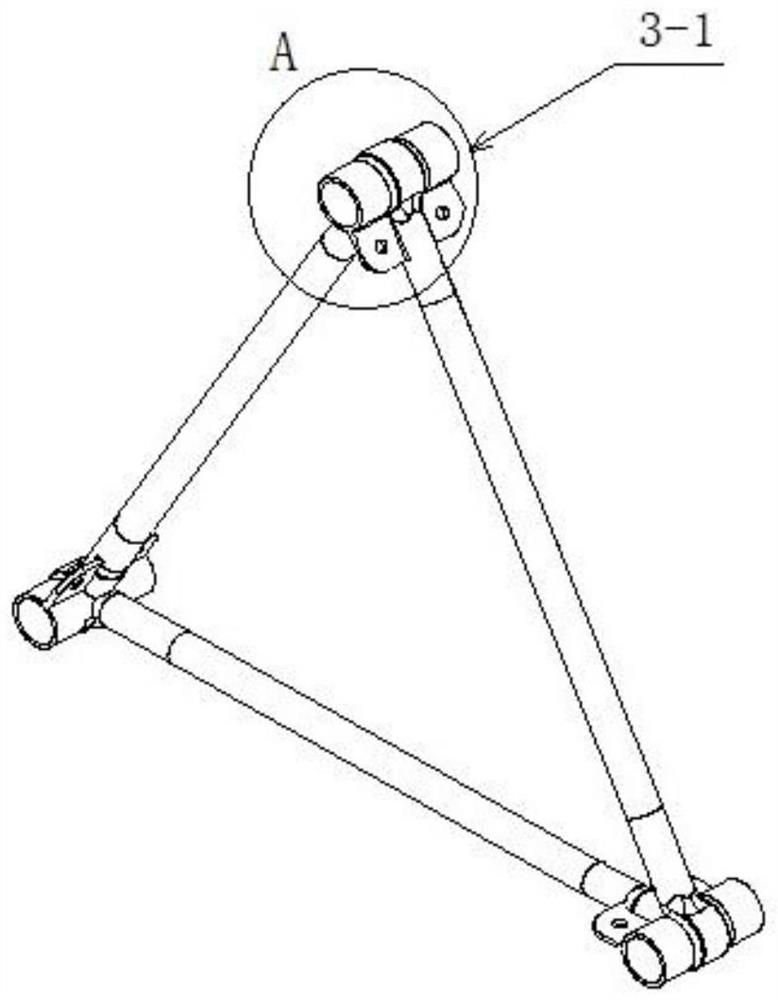

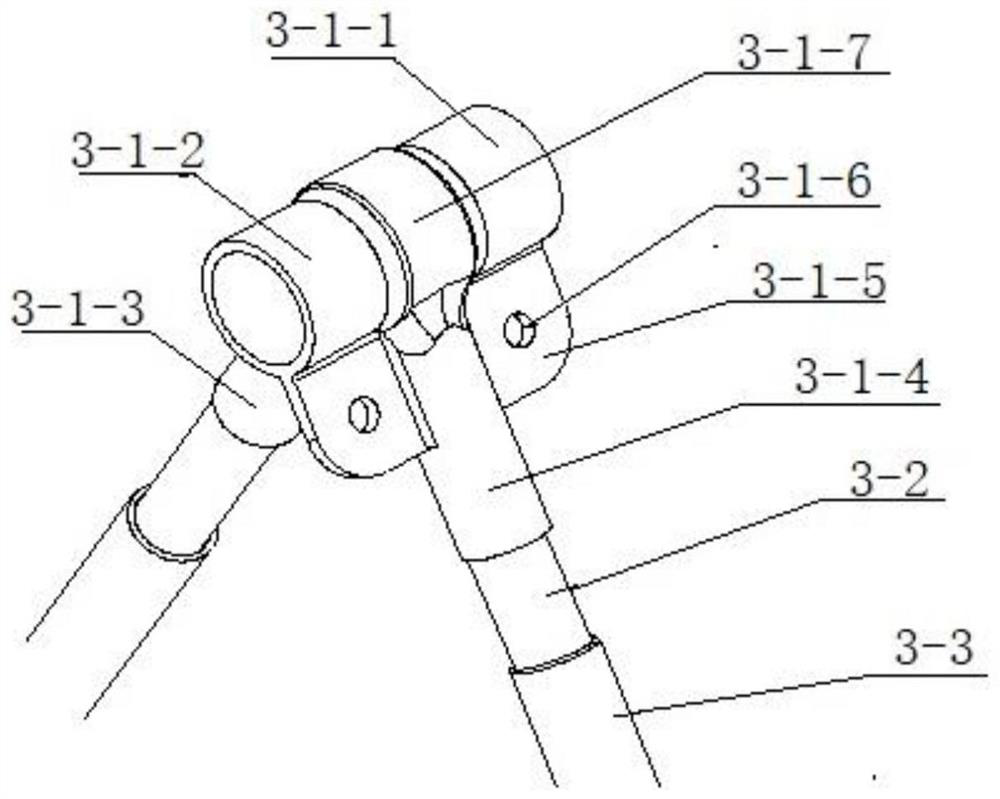

[0042] Such as figure 1 As shown, the triangular section arc-shaped composite material truss of this embodiment includes an outer chord 1, a first inner chord 2-1 and a second inner chord 2-2 parallel to each other, the outer chord 1, the first The inner chord 2-1 and the second inner chord 2-2 are connected in the same direction through evenly arranged triangular-section web members 3 and form an arc-shaped three-dimensional structure. The triangular-section web member 3 is passed through by three web members Three four-way joints 3-1 are connected in pairs, and the outer chords 1 and the first inner chords 2-1 between the adjacent triangular section web members 3 are provided with first outer oblique webs diagonally 4-1, and the adjacent first outer oblique web members 4-1 are staggered, and the outer chords 1 and the second inner chords 2-2 between the adjacent triangular section web members 3 are arranged diagonally The second outer oblique web 4-2, and the adjacent secon...

Embodiment 2

[0052] The preparation method of the arc tube in the triangular section arc-shaped composite material truss of this embodiment, that is, the outer chord 1, the first inner chord 2-1 and the second inner chord 2-2 is: The surface is covered with nylon air bags to form a soft inner mold, and then the epoxy resin high-strength carbon fiber prepreg is laid flat on the surface of the soft inner mold according to the designed layer structure to form a prefabricated body, and then the prefabricated body is placed in the lower mold cavity of the outer mold Inside the body, close and fasten the upper mold, pressurize to 0.8MPa ~ 1.1MPa, heat, heat and hold pressure for solidification and molding, and demould after cooling.

[0053] Such as Figure 7 As shown, the specific preparation process of the arc tube in the triangular cross-section arc-shaped composite truss of this embodiment, that is, the outer chord 1, the first inner chord 2-1 and the second inner chord 2-2 is: first accept ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com