High-precision sound film intelligent punching production line based on visual positioning function

A visual positioning, high-precision technology, used in metal processing, conveyor objects, transportation and packaging, etc., can solve problems such as errors and affect the quality of acoustic film punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following is attached Figure 1-14 The application is described in further detail.

[0058] The embodiment of the present application discloses a high-precision acoustic film intelligent punching production line based on the visual positioning function.

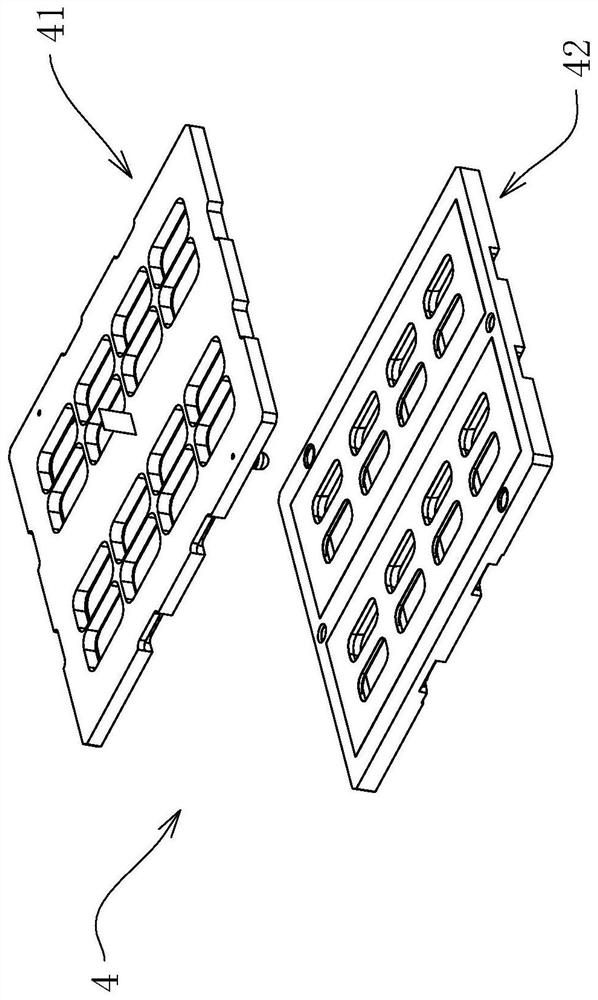

[0059] refer to figure 1 , is the sound film band and the jig assembly 4 for placing the sound film band. There are two sound film bands in total, and 8 sound films to be punched are evenly distributed on each sound film band, and the sound film is hollow and oval. The jig assembly 4 is divided into an upper jig 41 and a lower jig 42 , and the acoustic membrane tape is attached to the lower jig 42 and pressed by the upper jig 41 .

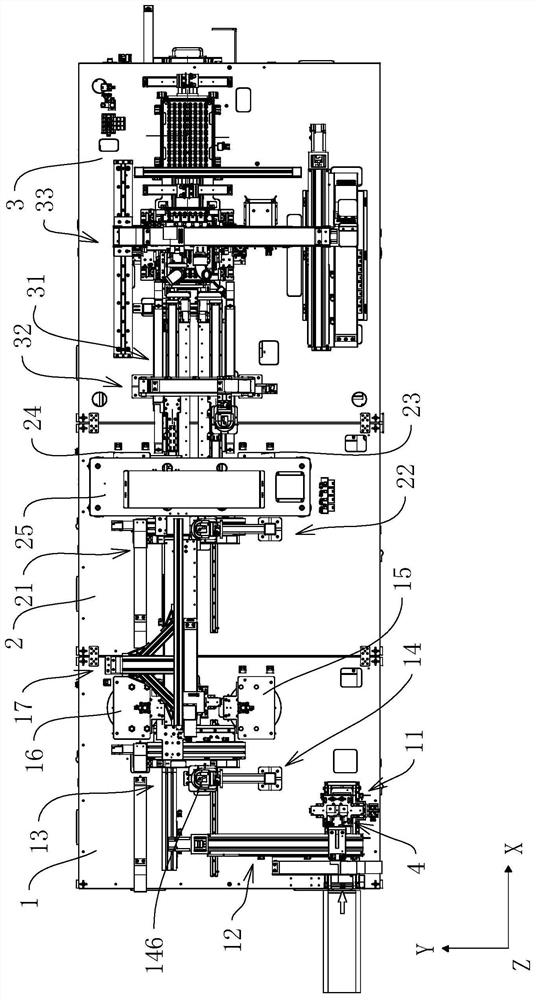

[0060] refer to figure 2 , the production line includes the first workstation 1, the second workstation 2 and the third workstation 3 in sequence along the processing direction of the acoustic membrane. The first workstation 1, the second workstation 2 and the third workstation 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com