Crisp and fragrant cartilage cutting machine and method

A cutting machine and cartilage technology, which is applied in poultry segmentation, poultry transfer/conveying devices, metal processing, etc., can solve the problems of low safety, uneven cartilage cutting, manual error deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

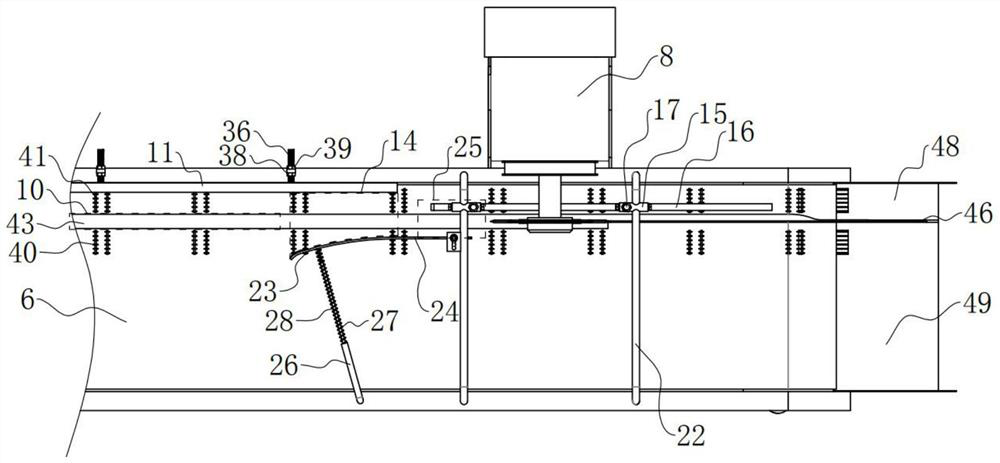

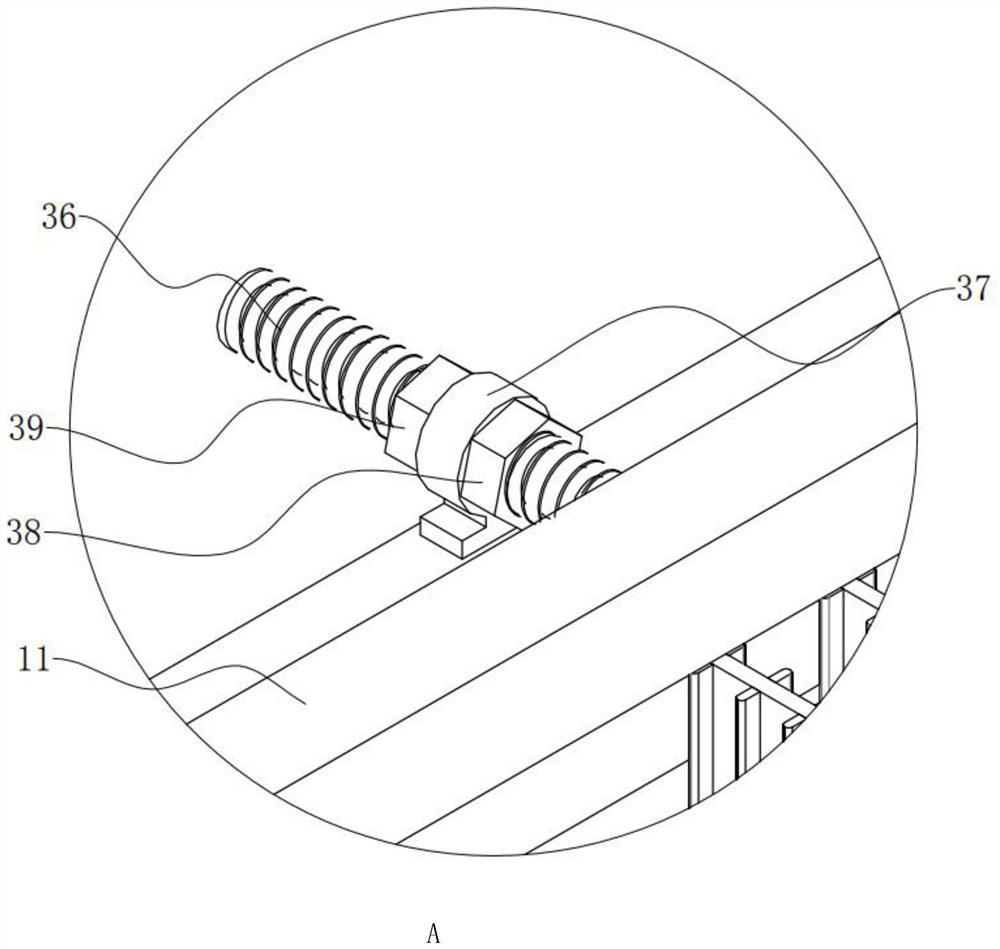

[0027] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings. It should be noted that the words "upper" and "lower" used in the following description refer to the attached figure 2 In the directions, the words "bottom" and "top" refer to the attached figure 1 and figure 2 In the direction towards the geometric center of a particular part; in addition, the "front end" and "rear end" in the text refer to the image 3 in the left and right directions.

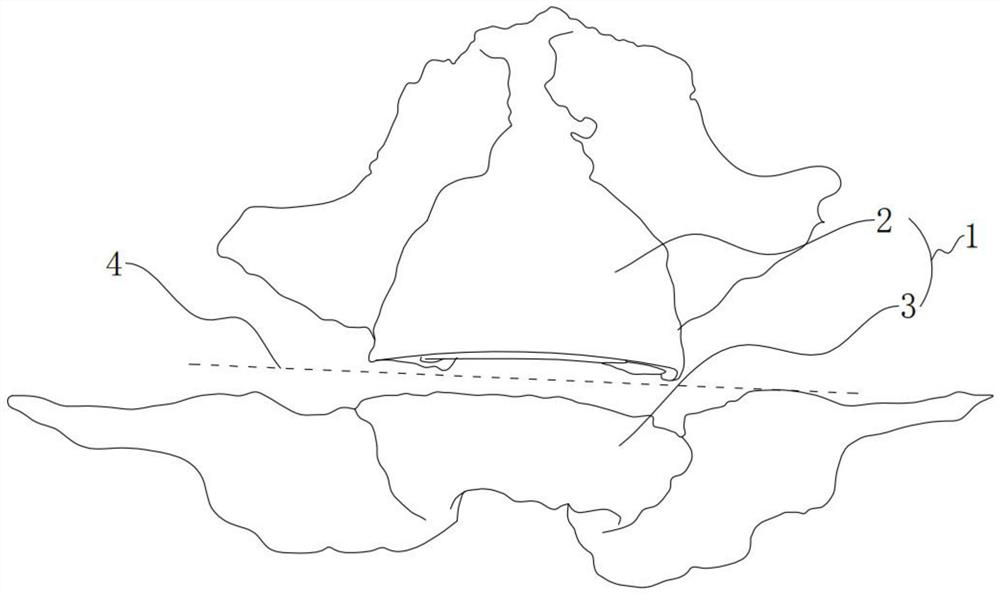

[0028]The most critical idea of the present invention is: by limiting and compressing the chicken raw material 1 to be cut multiple times during transportation, the subsequent cutting uniformity, cutting efficiency and safety are improved; through the conveying device 6 and the positioning block group 9 , and because the positioning block group 9 is provided with several,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com