High-precision wheelchair armrest fixing frame pipe bending device and working method

A bending device and wheelchair armrest technology, applied in the field of wheelchair manufacturing, can solve problems such as unfavorable maintenance and repair, complex structural design, complex bending operation, etc., and achieve the effects of easy manufacturing and use, convenient use, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

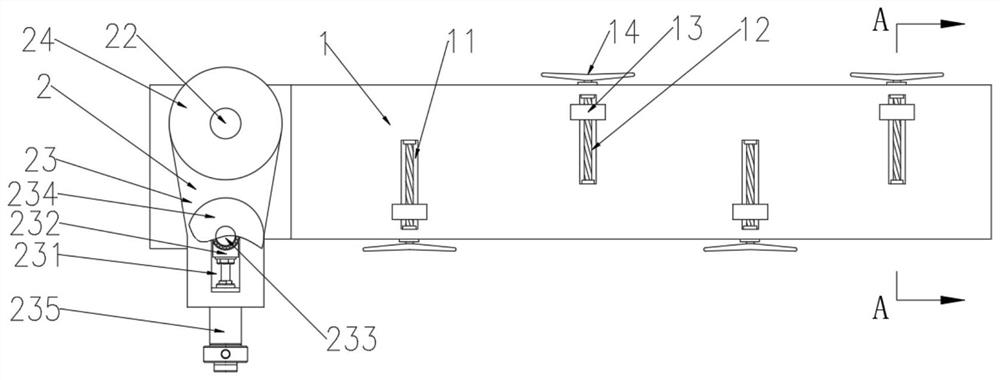

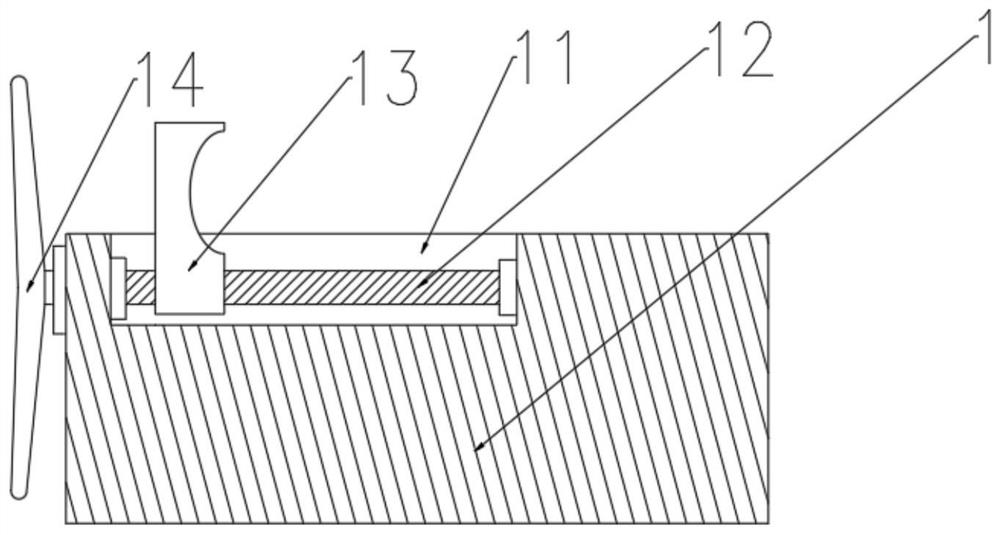

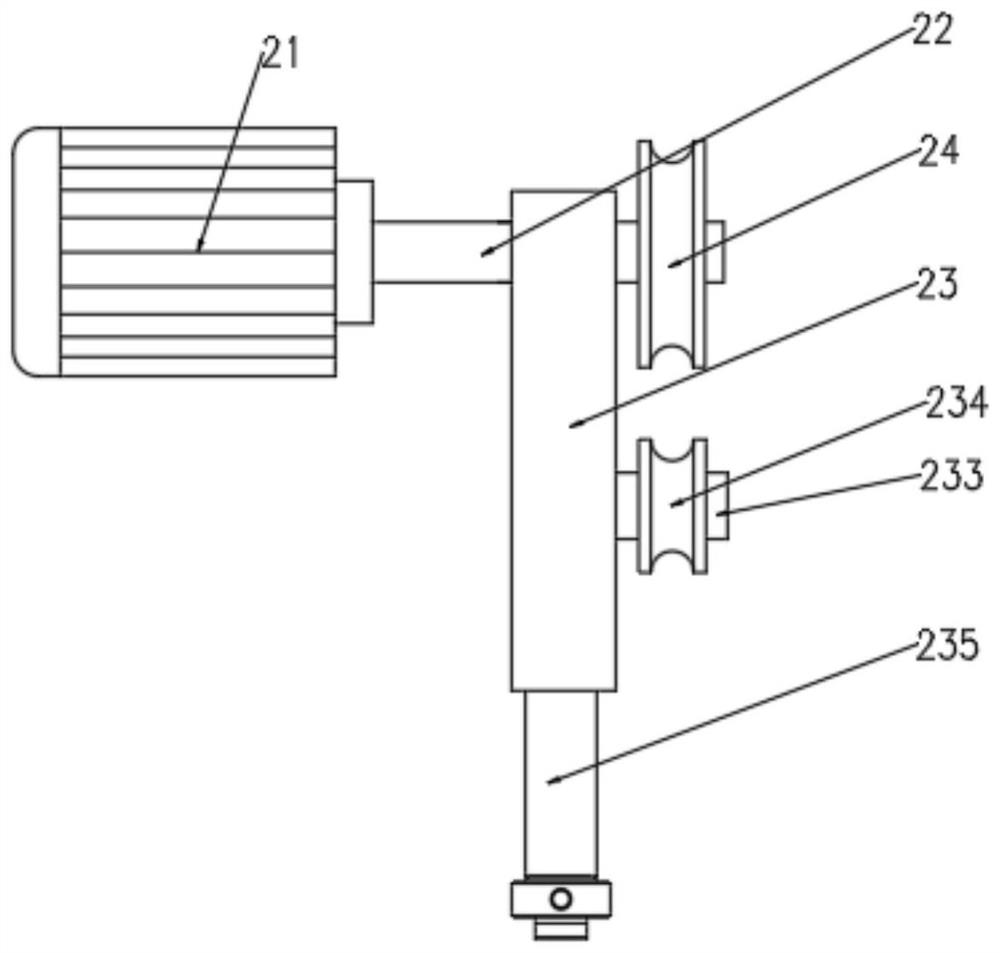

[0022] Such as Figure 1-3 As shown, a high-precision wheelchair armrest fixing frame pipe bending device and working method include a base plate 1 and a bending device 2, the bending device 2 includes a motor 21, and the rotor shaft 22 of the motor 21 passes through the base plate 1 is provided with a fixed seat 23 and an upper mold wheel 24, the fixed seat 23 is fixedly connected with the rotor shaft 22, the bending disc 24 is rotatably connected with the rotating shaft 22; the lower end of the fixed seat 23 is provided with a window 231, so The window 231 is provided with a slider 232, the slider 232 is provided with a first rotating shaft 233, the first rotating shaft 233 is rotatably connected with a lower mold wheel 234, and the lower end of the fixing seat 23 is provided with a hydraulic cylinder 235 , the piston rod of the hydraulic cylinder 235 passes upwards through the bottom of the window 231 and is connected with the slider 232 . The upper mold wheel 24 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com