A multi-directional spraying system and spraying process based on glass bottle production

A glass bottle, multi-directional technology, applied in coatings, spray booths, spraying devices, etc., can solve the problems of paint waste, prolonging the processing time of glass bottles, and not being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

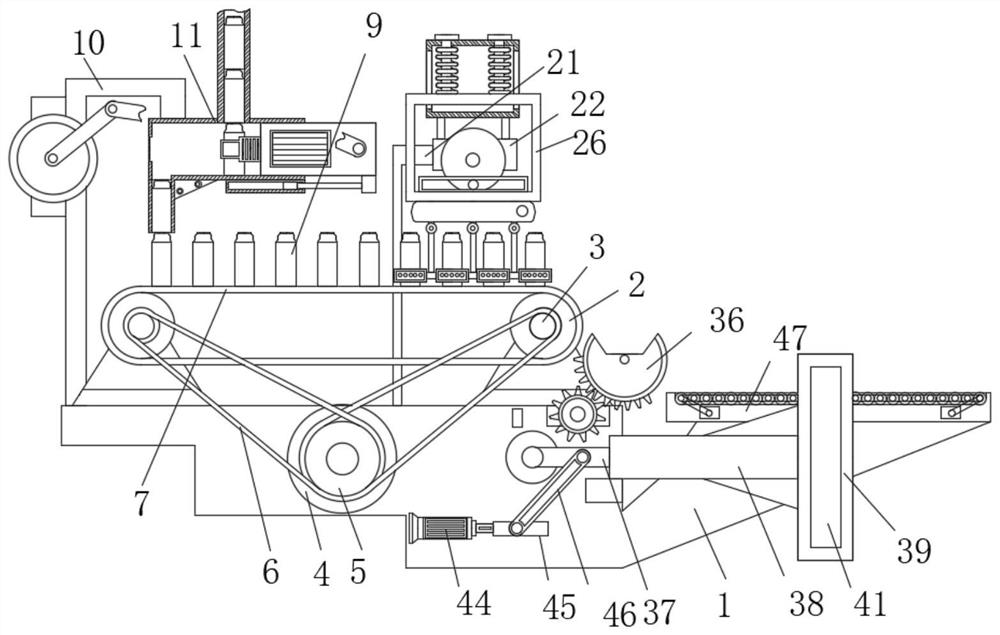

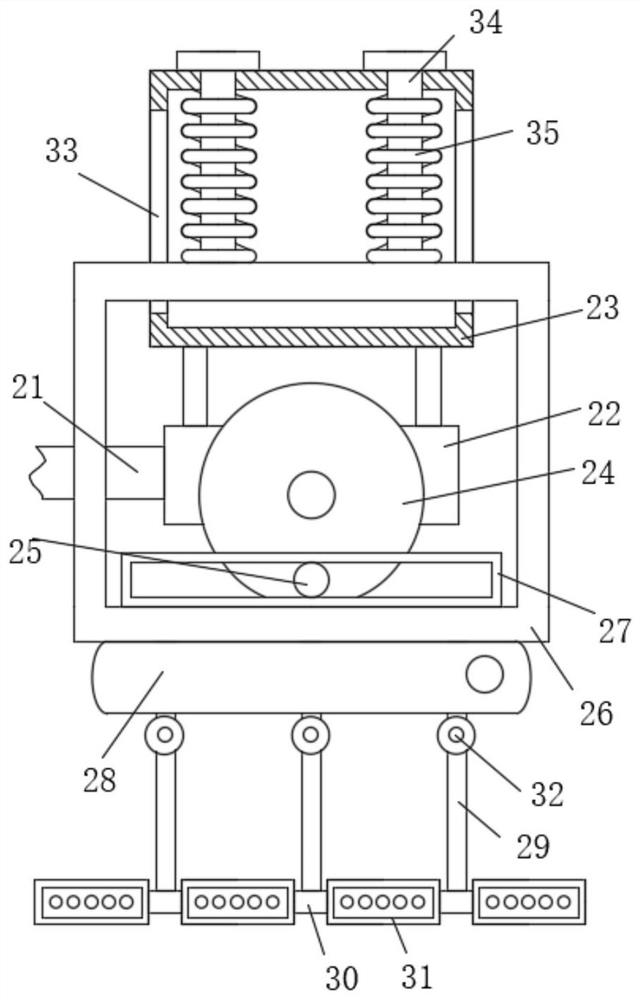

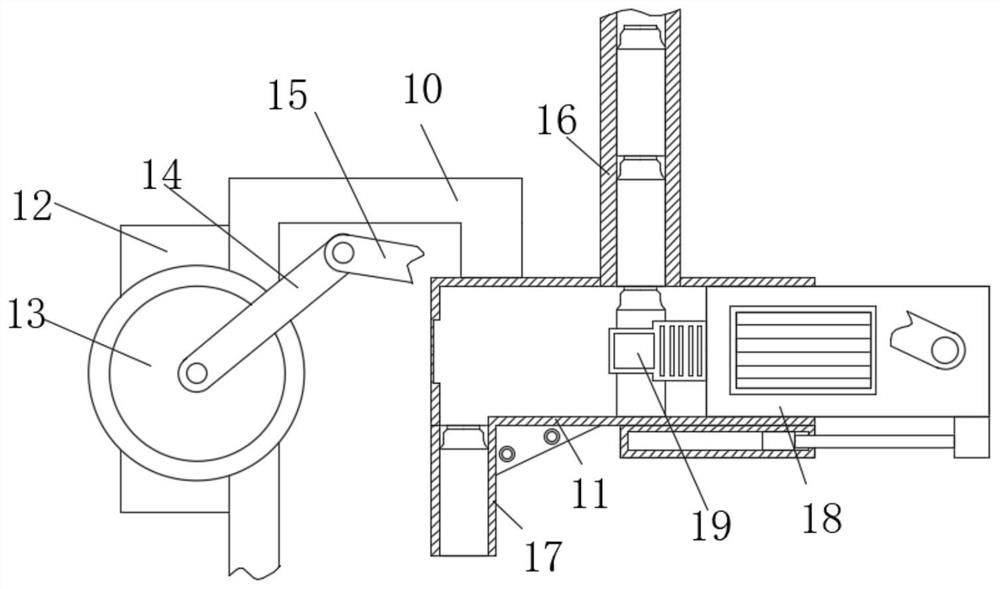

[0045] Embodiment one: if Figure 1-14 As shown, a multi-directional spraying system based on glass bottle production includes a mounting base 1. Two symmetrically arranged drive rollers 2 are installed on the top of the mounting base 1. One side of the mounting base 1 is provided with a driving drive roller. 2 The driving assembly that rotates at the same time, the outer sides of the two transmission rollers 2 are connected to the same conveyor belt 7, and the top of the conveyor belt 7 is equidistantly arranged with a plurality of glass bottles 9, and the top of the conveyor belt 7 is equipped with multiple The positioning holes 8 are arranged equidistantly in the horizontal direction, and the positioning holes 8 and the glass bottles 9 are compatible. When the glass bottles 9 fall into the designated positioning holes 8 through the feeding pipe 17, the positioning holes 8 can be used to improve the glass bottle. The stable performance of the bottle 9 movement, the top of th...

Embodiment 2

[0058] Embodiment two: if Figure 15 As shown, a multi-directional spraying system based on the production of glass bottles, the difference between this embodiment and Embodiment 1 is that: the discharge assembly 47 includes a discharge seat 4701, and the top of the discharge seat 4701 is provided with a strip-shaped transportation groove, and the transportation A plurality of transport rollers 4702 are rotatably connected to the inner wall of the bottom of the trough, and the plurality of transport rollers 4702 are connected by transmission. One side of the discharge seat 4701 is fixedly connected with two rotating cylinders 4704 arranged symmetrically. Two rotating rollers 4703 arranged symmetrically are rotationally connected, and the rotating rollers 4703 and the conveying rollers 4702 are connected by transmission. The second sprocket 4706 is fixedly installed on the center of one side of the rotating rollers 4703, and the output shaft of the rotating cylinder 4704 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com