Manufacturing method of comfortable full-mouth adsorption false tooth meeting aesthetic function

A production method and functional technology, applied in the direction of dentures, etc., can solve the problems of high requirements for technicians, high treatment costs, and low manufacturing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

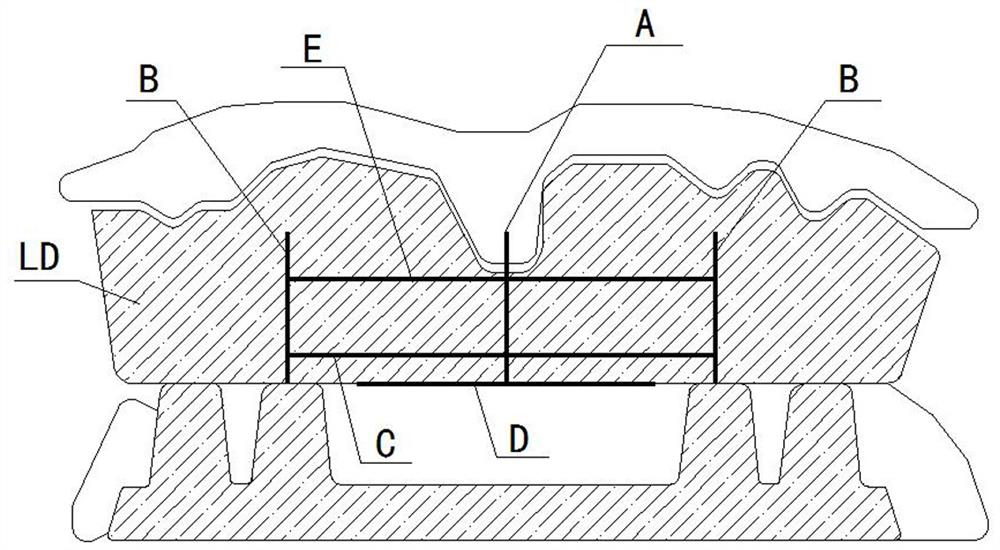

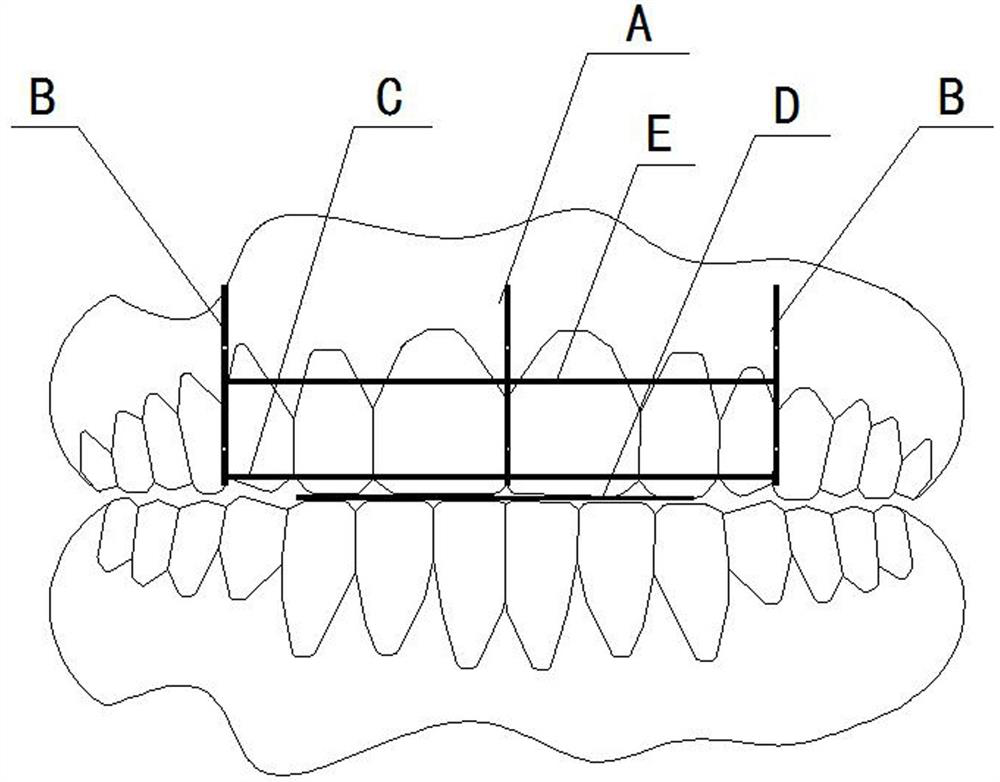

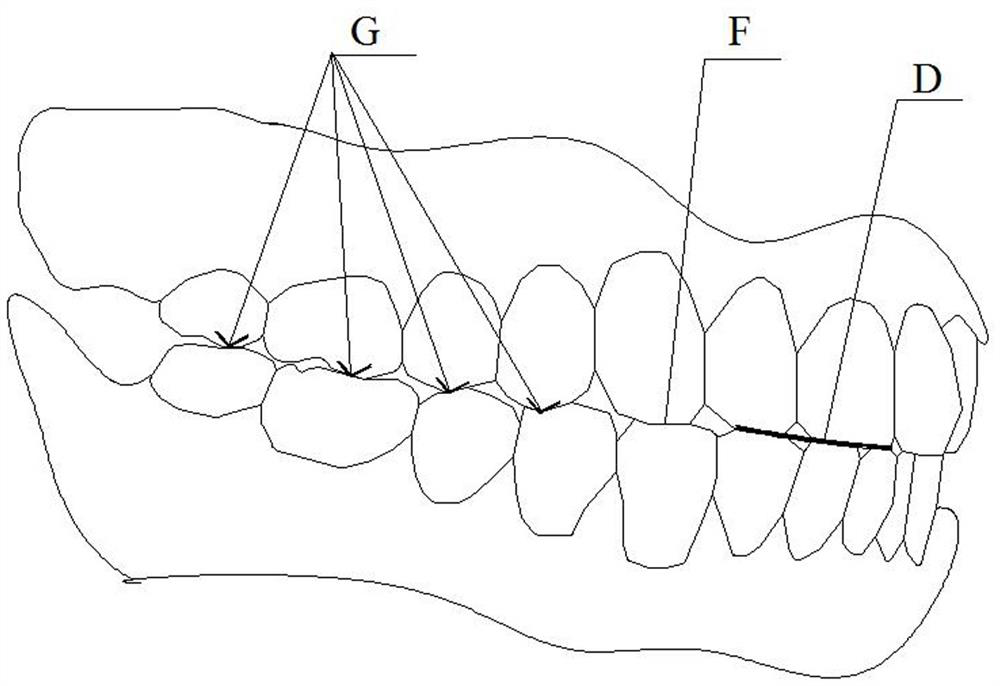

[0027] A method for making a comfortable full-mouth adsorption denture that satisfies the aesthetic function of the present invention is to use the vertical distance from the corner of the patient's eye to the corner of the mouth minus 2 to 3 mm as the size from the nose to the corner of the mouth on a temporary base bearing a wax embankment LD. The vertical distance from the bottom of the chin to the bottom of the chin, and the wax embankment on the temporary base was made according to this size. After the occlusal test, the midline A, the corner line B and the lip bottom line C were drawn on the wax embankment according to the actual situation of the patient, and then taken The bisector of the gap between the jaws after the occlusal test mouth, so far, the basic data of the patient’s denture p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com