Recombinant tobacco and preparation method of recombinant tobacco

A technology for recombining tobacco and tobacco, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation. It can solve the problems of low coating rate of finished reconstituted tobacco leaves, poor film base absorption performance, and low extraction rate of raw materials, so as to achieve controllable production operations. Strong, high absorption performance, highly restored the effect of intrinsic quality characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

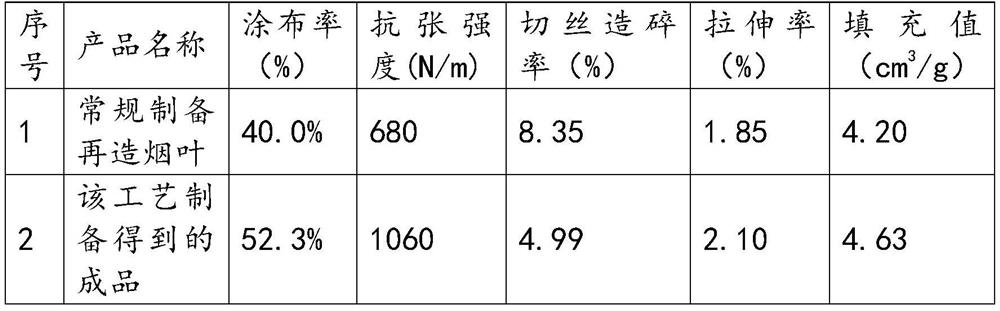

[0040] Tobacco raw materials are pulverized by crushing equipment to prepare superfine tobacco powder. The median diameter (D50) of superfine tobacco powder is 50.19um, and the particle size content of less than 20um is 25.26%. Take 87 parts (dry weight) of the above-mentioned Put the ultra-fine tobacco powder in an extraction tank, add 4.6 times the mass of water to it, and extract at 70°C for 30 minutes. After the extraction is completed, filter to obtain the extract and filter residue, and concentrate the extract to obtain a concentrate. Add 1 part of the concentrate to the concentrate Prepare the coating solution after blending high-quality flavor and fragrance for later use;

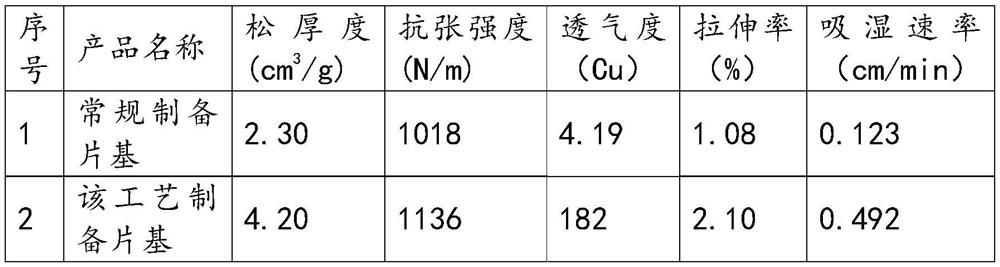

[0041] Get 13 parts of quality cellulose fibers (wherein hemp pulp accounts for 10 parts and wood pulp accounts for 3 parts), and pulping is carried out by the reconstituted tobacco leaf pulping process of papermaking method. After the completion, mix the tobacco powder residue and the cellulose fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com