Cooking-resistant improver for frozen flour products as well as preparation method and application of cooking-resistant improver

A technology of frozen noodles and cooking resistance, applied in the application, food ingredients as thickeners, food ingredients, etc., can solve the problems of damage to consumers' health, high price, and insignificant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

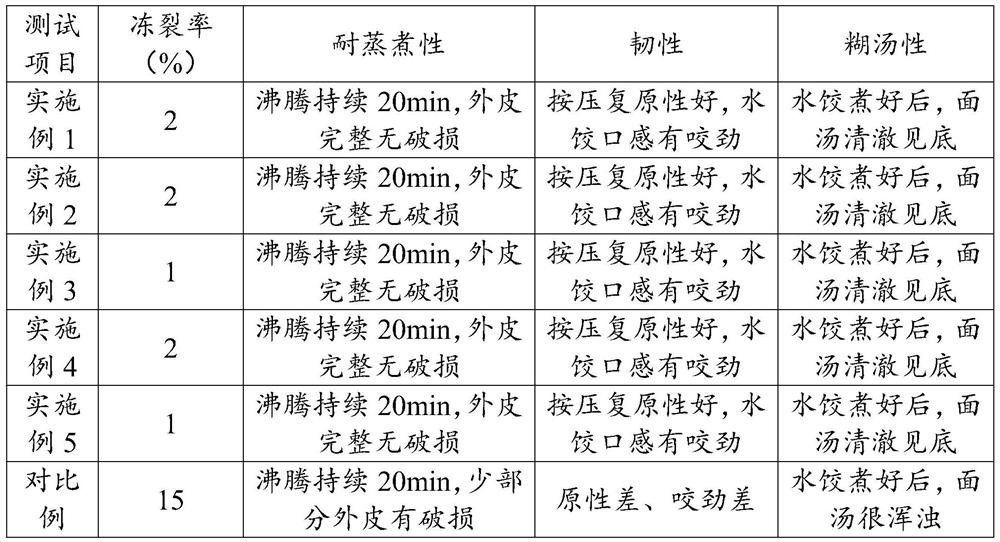

Examples

Embodiment 1

[0031] The retort improving agent for frozen noodle products, including the following raw materials: 30 kg of sodium carboxymethyl cellulose, 25 kg of xanthan gum, 15 kg of sodium tripolyphosphate, 5 kg of L-cysteine and 3 kg of phosphate monoester;

[0032] The preparation method of the retort-resistance improver for frozen noodle products specifically comprises the following steps:

[0033] (1) Take each raw material by the weight of the above-mentioned frozen noodle product retort resistance improver;

[0034] (2) sodium carboxymethylcellulose, xanthan gum, sodium tripolyphosphate, L-cysteine and phosphoric acid monoester are passed through 80 mesh sieves respectively;

[0035] (3) Add the sieved sodium carboxymethylcellulose, xanthan gum and sodium tripolyphosphate into deionized water, stir at a speed of 100r / min for 30min until uniformly mixed, and obtain a mixed solution;

[0036] (4) Add sieved L-cysteine and phosphoric acid monoester to the mixed solution, stir...

Embodiment 2

[0038] Retort improving agent for frozen noodle products, including the following raw materials: 35 kg of sodium carboxymethyl cellulose, 28 kg of xanthan gum, 18 kg of sodium tripolyphosphate, 6 kg of L-cysteine and 4 kg of phosphate monoester;

[0039] The preparation method of the retort-resistance improver for frozen noodle products specifically comprises the following steps:

[0040] (1) Take each raw material by the weight of the above-mentioned frozen noodle product retort resistance improver;

[0041] (2) sodium carboxymethylcellulose, xanthan gum, sodium tripolyphosphate, L-cysteine and phosphoric acid monoester are passed through 80 mesh sieves respectively;

[0042] (3) Add the sieved sodium carboxymethylcellulose, xanthan gum and sodium tripolyphosphate into deionized water, stir at a speed of 100r / min for 30min until uniformly mixed, and obtain a mixed solution;

[0043] (4) Add sieved L-cysteine and phosphoric acid monoester to the mixed solution, stir at ...

Embodiment 3

[0045] The retort improving agent for frozen noodle products includes the following raw materials by weight: 45kg of sodium carboxymethylcellulose, 32kg of xanthan gum, 22kg of sodium tripolyphosphate, 9kg of ascorbyl palmitate and 6kg of hydroxyalkyl starch;

[0046] The preparation method of the retort-resistance improver for frozen noodle products specifically comprises the following steps:

[0047] (1) Take each raw material by the weight of the above-mentioned frozen noodle product retort resistance improver;

[0048] (2) Sodium carboxymethylcellulose, xanthan gum, sodium tripolyphosphate, ascorbyl palmitate and hydroxyalkyl starch are passed through 120 mesh sieves respectively;

[0049] (3) Add the sieved sodium carboxymethylcellulose, xanthan gum and sodium tripolyphosphate into deionized water, stir at a speed of 150r / min for 40min until uniformly mixed, and obtain a mixed solution;

[0050] (4) Add sieved ascorbyl palmitate and hydroxyalkyl starch to the mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com