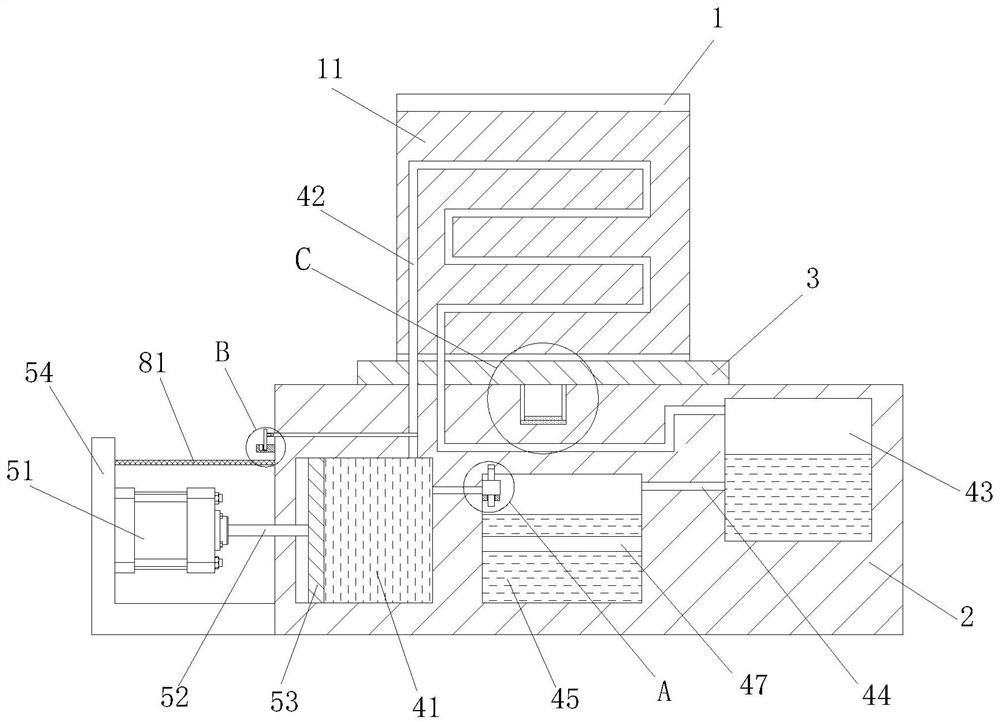

Cooling system for oven door of cooking oven

A cooling system and oven door technology, which is applied in the direction of oven doors/flap gates, etc., can solve the problems of easy burns and burns on the skin, and achieve the effects of saving water resources and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

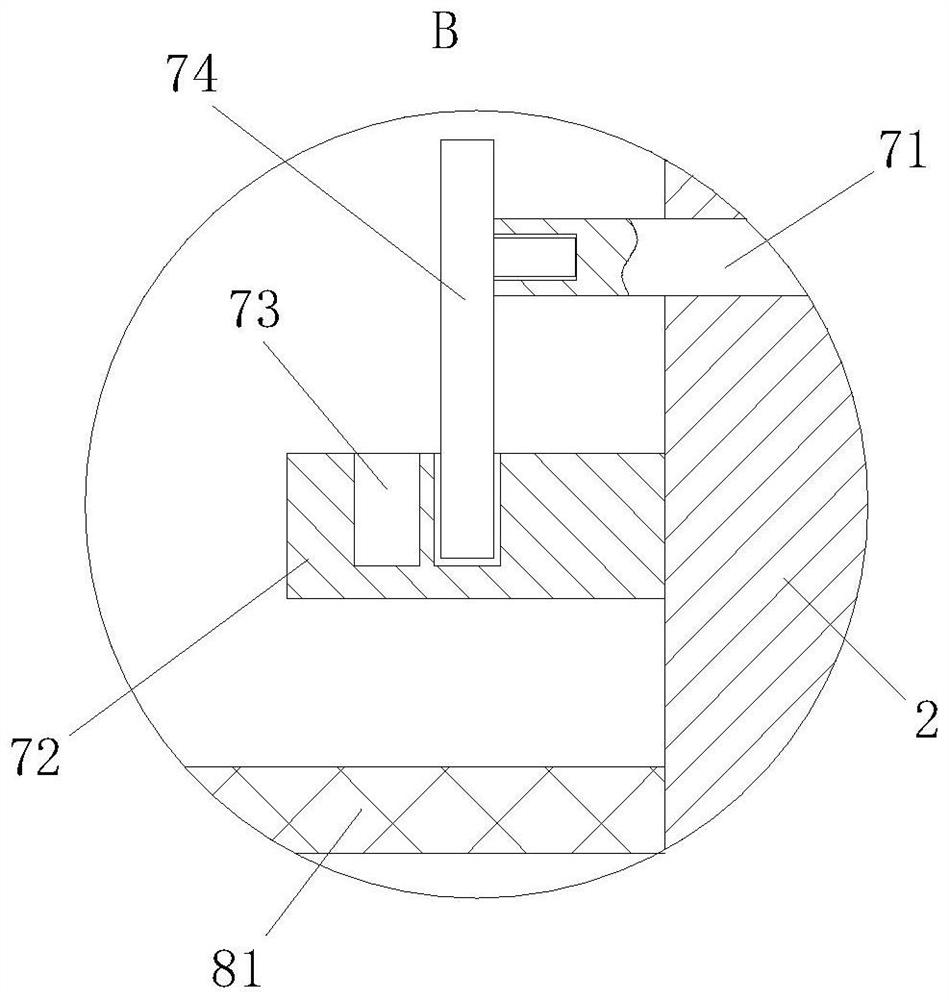

[0023]As an embodiment of the present invention, the drive mechanism includes a tacho 51, a push rod 52, and a push plate 53; the side wall of the base 2 is fastened to a L-shaped support plate 54; the cylinder 51 is fixed The sidewall of the L-shaped support plate 54; the push rod 52 is fixed to the output terminal of the electrical cylinder 51; the push plate 53 is slidably connected to the interior of the No. 1 cavity 41; the push rod 52 is solid to the push plate 53 When used, the cylinder 51 is activated so that the electrical cylinder 51 moves toward the right movement to the right, so that the push plate 53 will extrud the cold water inside the No. 1 cavity 41, so that the cold water flows out from the No. 1 water pipe 42, and realizes the oven The cooling of the door 11, then flows into the second cavity 43 and the third cavity 45, and finally return to the interior of the No. 1 cavity 41, and the circulation flow and cyclic use of water are realized, and the waste of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com