Angle-adjustable lens base

A lens holder and lens technology, applied in installation, optics, instruments, etc., can solve the problems of complex support structure, poor rigidity, high cost, etc., and achieve the effect of simple operation, low cost, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

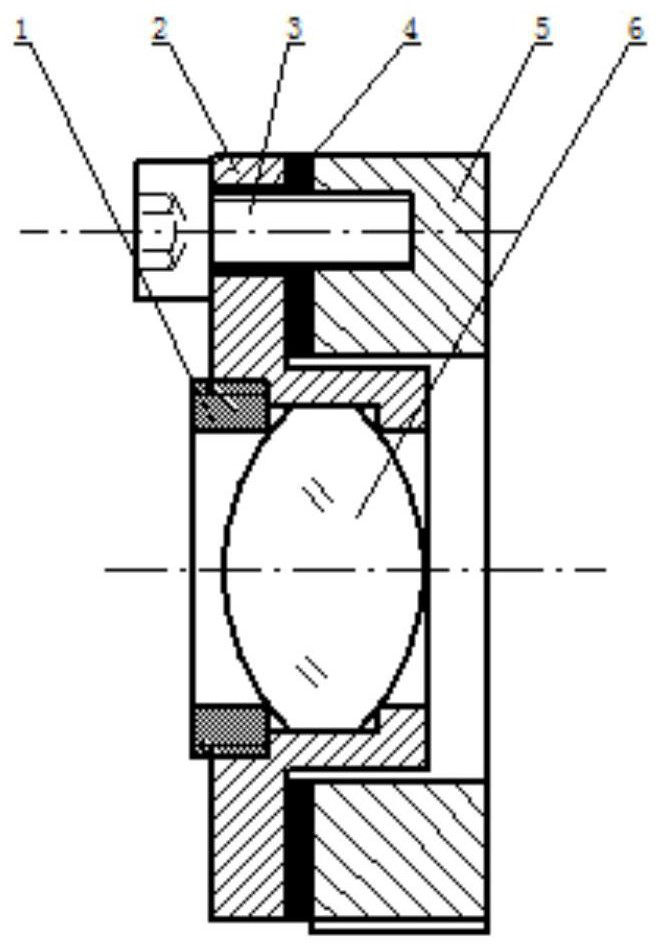

[0012]DETAILED DESCRIPTION One: Combinationfigure 1In the present embodiment, an angularly adjustable lens base includes a lens compression ring 1, a lens seat 2, and a base 5, wherein the mounting base 5 is fixed on an optical platform, and the mounting base 5 is opened. The through hole is mounted, and the lens seat 2 has a "convex" glyph structure and there is a three-stage step through hole thereof, and the lens seat 2 is fixed to the mounting base 5 and secured between the mounting base 5. , There is a regulating spacer 4 between the shoulder surface of the lens seat 2 and the end face of the mounting base 5, and the lens 6 is mounted in the middle of the three-stage step through hole and one end surface is passed through the lens pressure in the three-stage step through the surface. Circle 1 fixed position. The three-stage step through hole is from left to right to one-stage through hole. The lens 6 is fitted within the secondary through hole, and both ends of the lens 6 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com