Air seal type wet spraying machine discharging system and using method thereof

A wet spraying machine and air sealing technology, which is applied in underground chambers, earthwork drilling, spraying devices, etc., can solve the problems of equipment damage, high air pressure at the discharge port, and large wear of the distributor equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

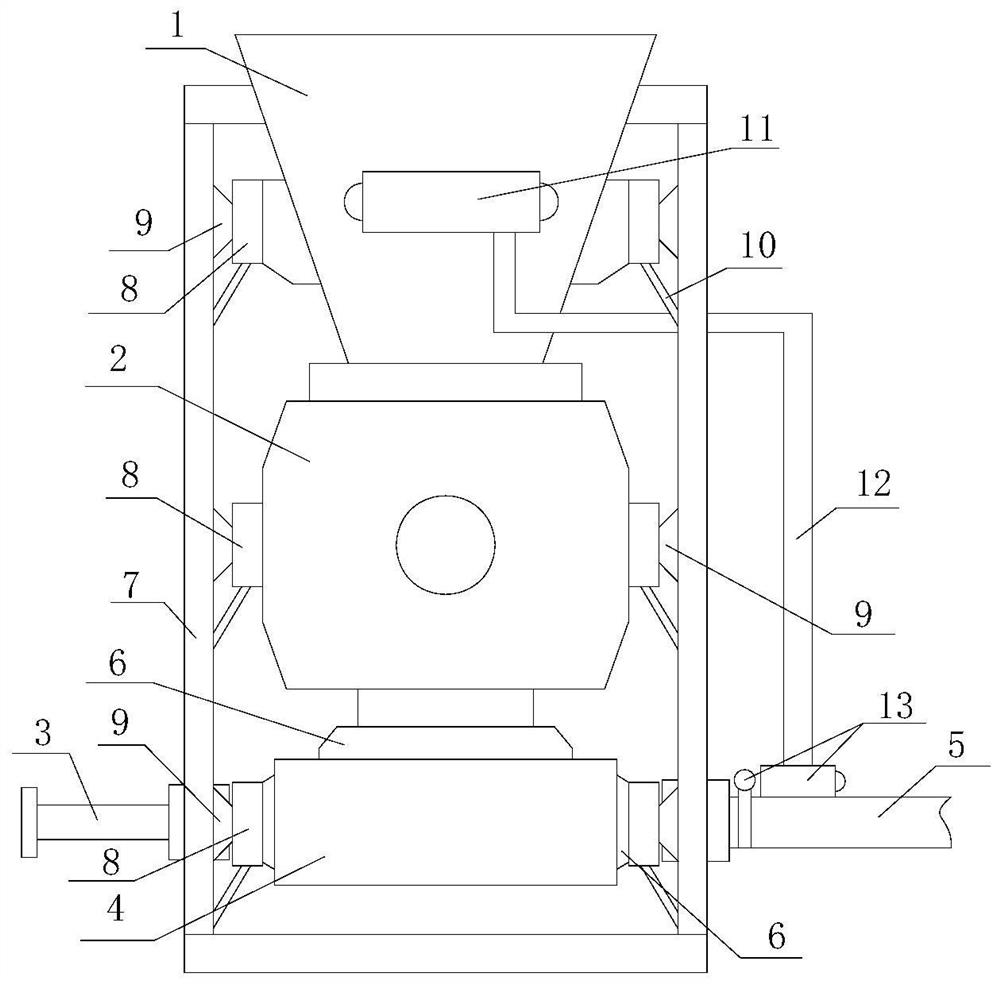

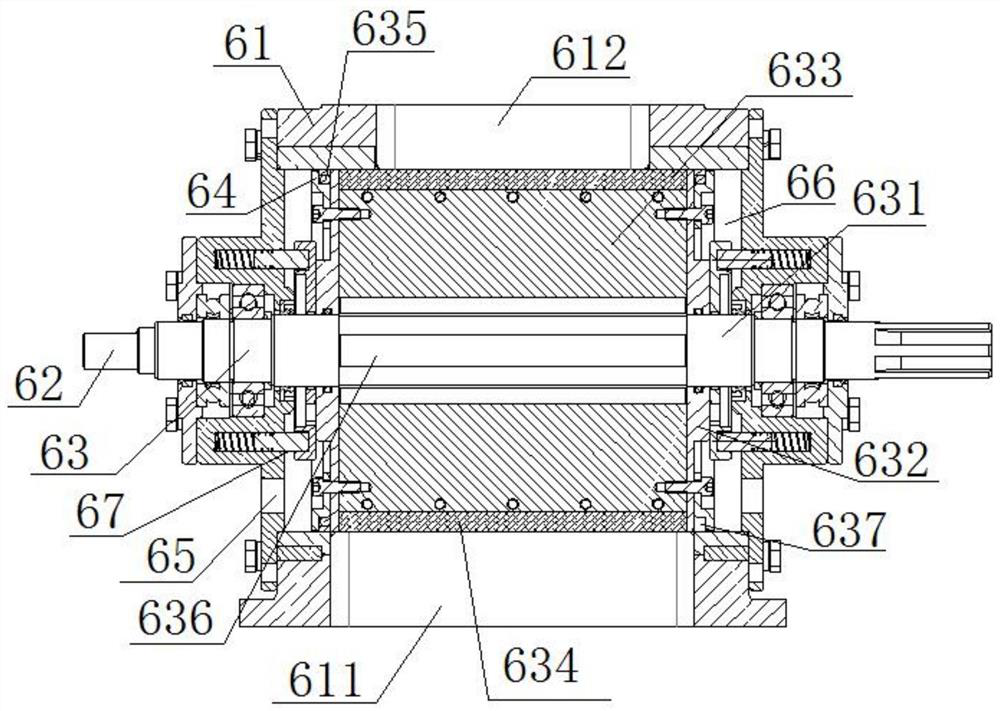

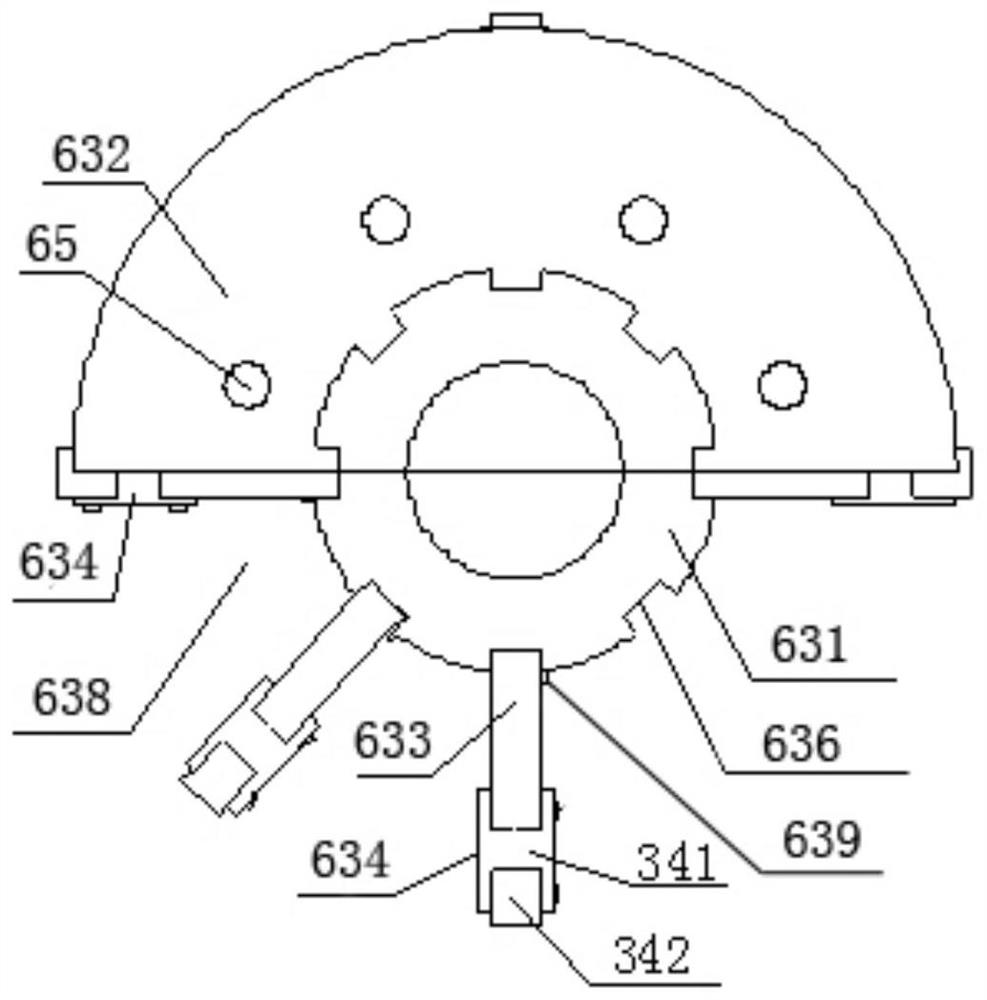

[0023] Such as figure 1 As shown in -3, a kind of air-sealed wet spraying machine blanking system comprises a lower hopper 1, a material distributor 2, a discharge pipe 3, a material receiving tray 4, and a high-pressure air pipe 5, wherein the upper end surface of the material distributor 2 is connected to the lower surface The hopper 1 is connected, and the lower end surface is connected with the material receiving tray 4, and the lower hopper 1, the distributor 2, and the material receiving tray 4 are coaxially distributed, and the front end surface and the rear end surface of the material receiving tray 4 are provided with a diversion port 6. The front end surface of the material tray 4 communicates with the discharge pipe 3 through the diversion port 6, and the rear end face communicates with the high-pressure air pipe 5 through the diversion port 6. The lower hopper 1 is a groove-shaped structure with an inverted isosceles trapezoidal axial section. The material receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com