Textile yarn waxing device

A technology for spinning yarns and yarns is applied in the field of textile yarn waxing devices, which can solve the problems of uneven waxing, easy to fall into wax blocks, damage to wax blocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

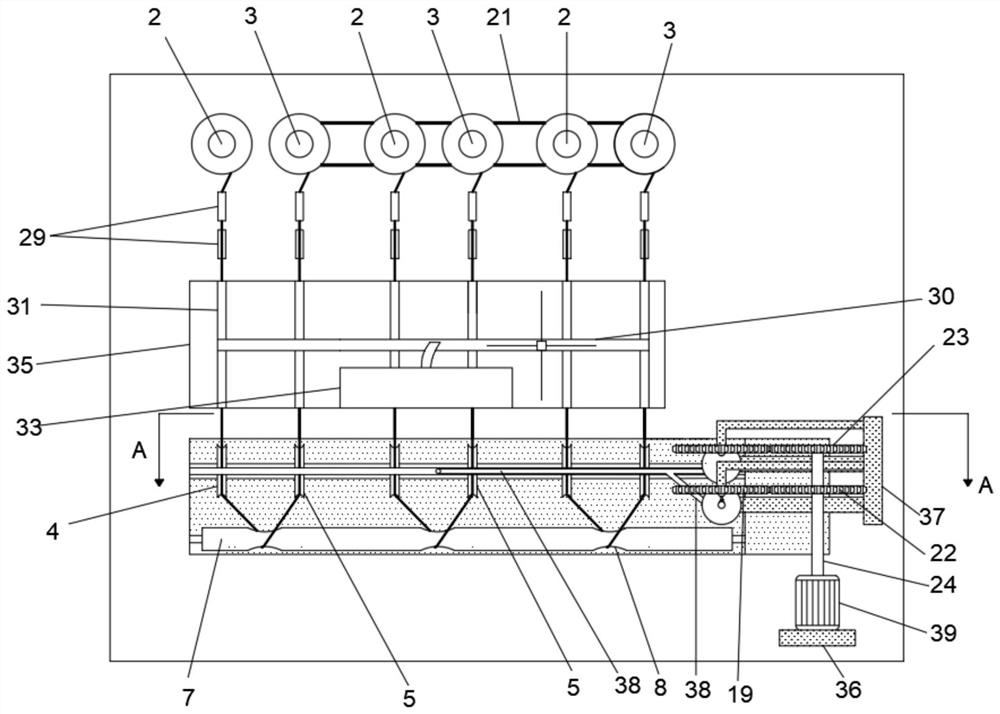

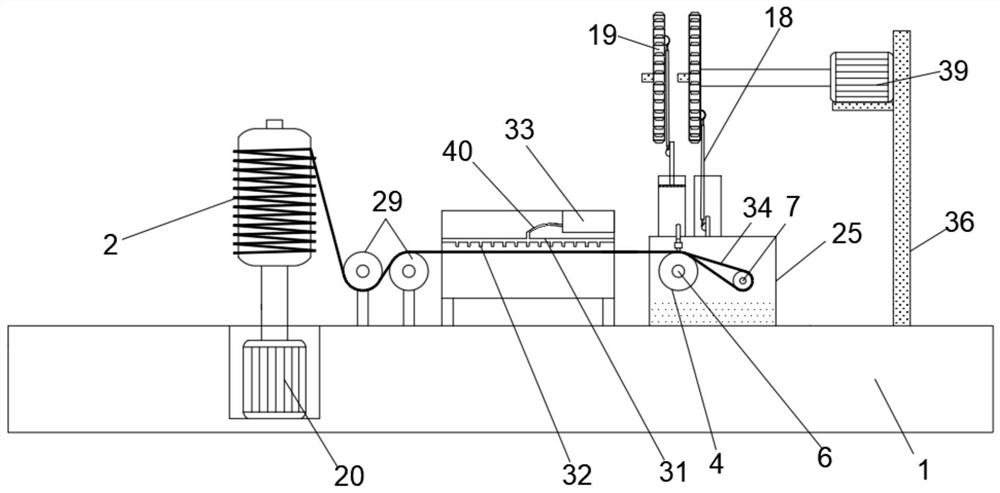

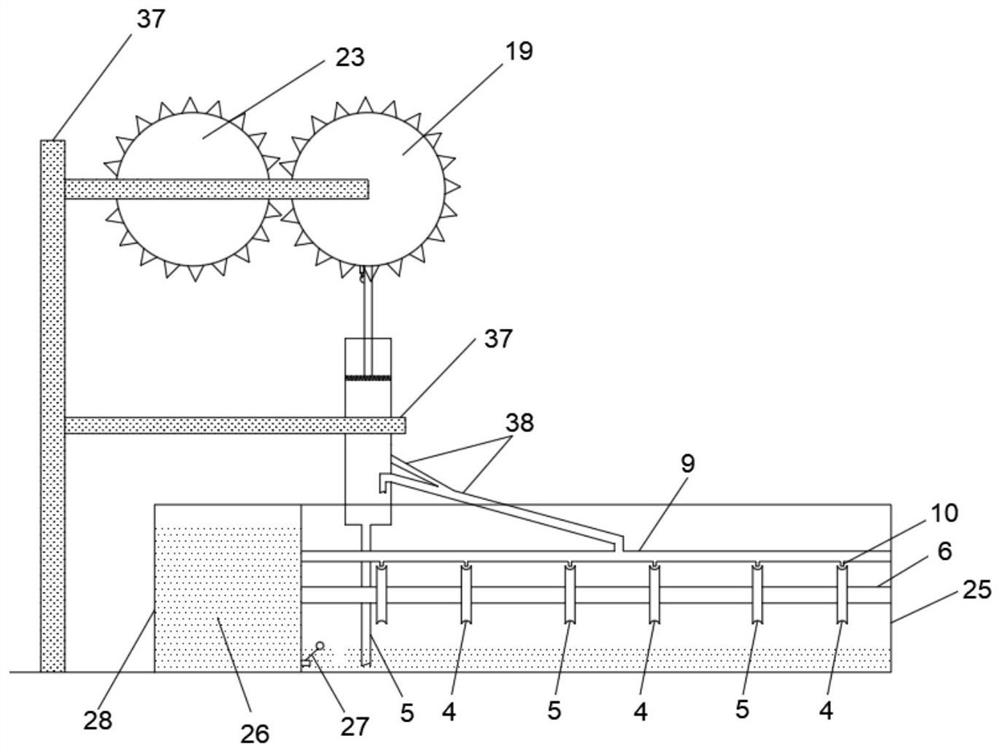

[0035] Such as Figure 1-5 As shown, the present invention provides a kind of textile yarn waxing device, comprising:

[0036] base1;

[0037]The pay-off and take-up mechanism, which is located on the base 1, includes a plurality of sets of pay-off and take-up reels arranged side by side, and each pay-off and take-up group includes a pay-off reel 2 and a take-up reel 3 that are all vertically arranged. One end of the spool 2 and the take-up spool 3 is rotatably connected to the base 1. Specifically, one end of each pay-off spool 2 and each take-up spool 3 is mounted on the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com