System and method for organic solid waste low-tar gasification combined heat and power supply

A technology of organic solid waste and cogeneration of heat and power, which is applied in the field of solid waste resource utilization, can solve problems such as unstable gas quality and difficult control of tar content, achieve improved energy efficiency, wide applicability of raw materials, and increase carbon conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

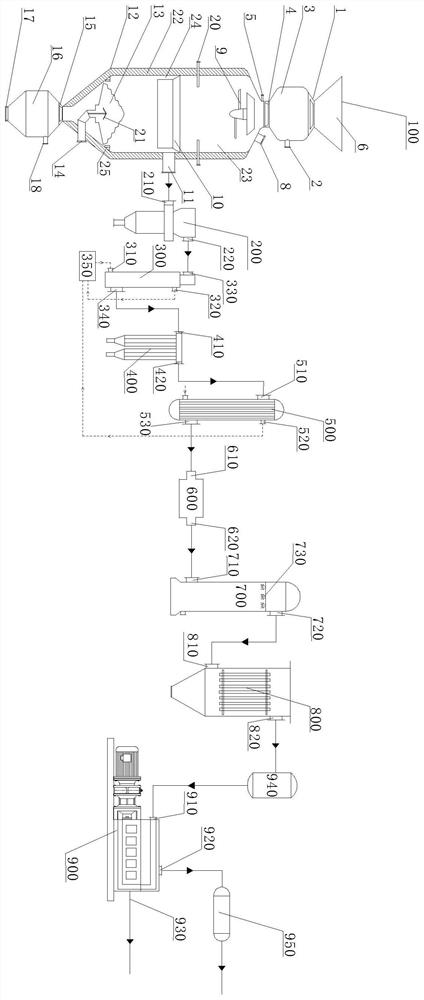

[0096] Organic solid waste low-tar gasification combined heat and power system such as figure 1 As shown, it includes a double oxide layer gasifier 100, a cyclone dust collector 200, a phenol water heat exchanger 300, an air cooler 400, an intercooler 500, a booster 600, a desulfurization tower 700, a bag filter 800 and an internal combustion unit 900 etc.

[0097] Homogeneous organic solid waste or formed RDF is transported to the feeding device after drying and other pretreatments, and enters the furnace of the gasifier through the feeding buffer bin; during the feeding process, when the material enters the feeding buffer bin, the feeding buffer The upper valve of the feed buffer bin is opened, and the lower valve of the feed buffer bin is closed. When the feed buffer bin enters the transition bin, the upper valve of the feed buffer bin is closed, and the lower valve of the feed buffer bin is opened. After the material enters the gasification furnace, it is evenly distribut...

Embodiment 2

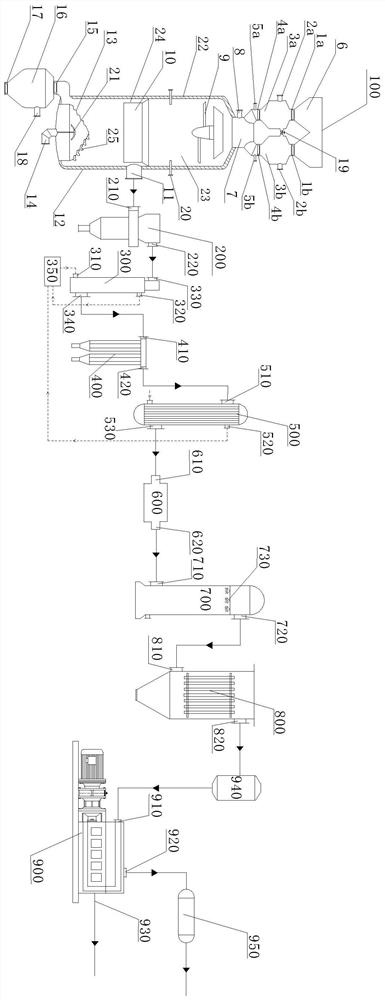

[0101] Such as figure 2 As shown, the difference from Example 1 is that the feeding device adopts double feeding channels; the slagging method adopted by the gasifier is side dry slagging, that is, the ash is rotated to the gasifier under the action of the grate The bottom side, under the action of the scraper, enters the slag chamber from the side and then discharges.

Embodiment 3

[0103] Such as image 3 As shown, the difference from Example 1 is that the slag removal method adopts the wet ash tray slag discharge, which is as follows: the gasified ash slag forms the ash tray water seal under the joint action of the grate, the ash tray and the slag ring, and there is also The scraper is welded on the furnace body and the slag ring, and the ash and slag are broken and slag is discharged during the rotation process; due to the certain pressure in the furnace, the water in the ash tray can be squeezed to a certain height to achieve a hydraulic seal. When the internal pressure is too large, the gas will emerge from the water to release the pressure safely, avoiding the safety hazard of explosion caused by the excessive pressure in the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com