Adjustable gold nanostructure as well as preparation method and application thereof

A gold nanostructure and nanoseed technology, applied in the field of nanomaterials, can solve problems such as complex processing of hard templates, changing nanostructure growth conditions, etc., to achieve good catalytic activity and mass activity, improved catalytic performance, and good anti-aggregation properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

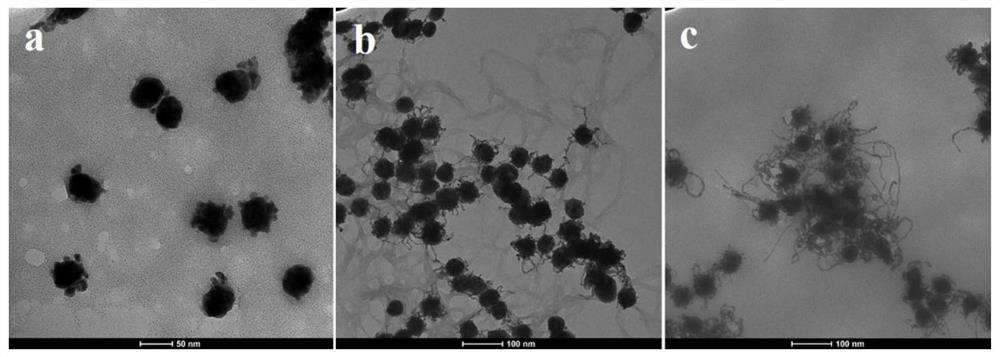

[0047] Synthesis of 3D gold nanograss and gold nanoislands:

[0048] APTES solutions with concentrations of 0.1mM, 0.01mM, and 0.6μM (pH 5, solvent mixed with ethanol and water) were added to 4ml vials, and the prepared 15nm gold nanoparticles were added thereto. The mixture was left to stand for 1 hour. A growth solution containing 4-mercaptophenylacetic acid (4-MPAA), chloroauric acid, and ascorbic acid was added to each vial under vigorous stirring to induce nanowire growth, wherein The molar ratio is 1:3:3. After 5 min of growth, the reaction was terminated with ethanol. The gold nanostructures obtained under different APTES concentrations are as follows figure 1 shown. figure 1 a obtained the gold nano-island structure, figure 1 b, c obtained gold nanograss structure.

[0049] In addition, gold nanorods, gold nanotriangular sheets and gold nanocubes are used to replace gold nanoparticles to carry out the above steps, and the obtained gold nanograss-like structure is...

Embodiment 2

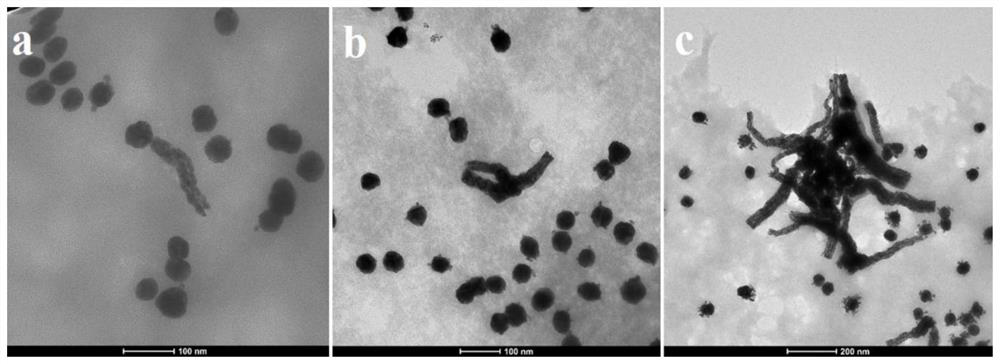

[0051] Synthesis of 3D Gold Nanotadpole Structures:

[0052] APTES solution (0.1 mM concentration, pH 7, solvent is a mixed solution of ethanol and water) was first mixed with PVA for 10 minutes and then added to a 4 ml vial, and the prepared 40 nm gold nanoparticles were added thereto. The mixture was left to stand for 1 hour. A growth solution containing 4-mercaptophenylacetic acid (4-MPAA), chloroauric acid, and ascorbic acid was added to the vial under vigorous stirring to induce the growth of the nanowires, where moles of 4-mercaptophenylacetic acid, chloroauric acid, and ascorbic acid The ratio is 2:1:1. After 10 min of growth, the reaction was terminated with ethanol.

[0053] The obtained gold nanostructures are as image 3 shown. Gold nano tadpole structures with different numbers of tails can be obtained by changing the action time of APTES and PVA.

Embodiment 3

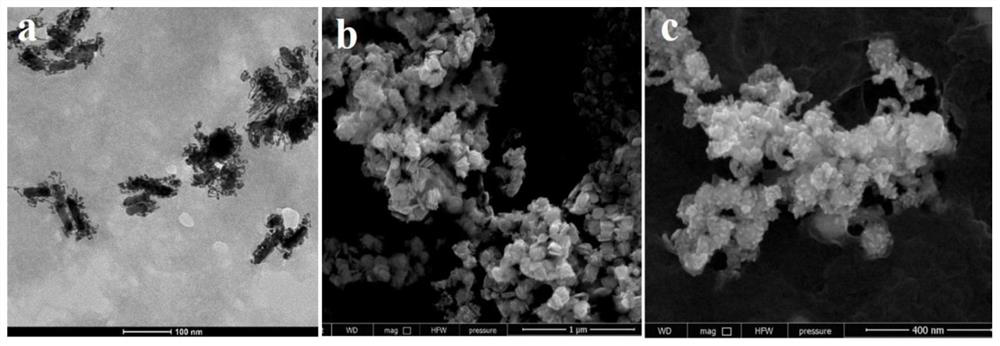

[0055] Synthesis of three-dimensional pompom-like gold nanosprings:

[0056] The APTES and PVP solutions were fully mixed, wherein the concentration of APTES was 1 μM, the solvent was a mixed solution of ethanol and water, the pH was 8, the concentration of PVP was 0.05M, and the molecular weight of PVP was 40,000. Silica nanoparticles of 20 nm diameter were then added. APTES hydrolyzes and condenses on the silica surface, providing surface amine groups. After 1 hour, gold nanoparticles with a particle size of 40 nm were added to allow the amine-functionalized silica nanoparticles to attach to the surface of the gold nanoparticles. Then add the ligand 4-mercaptophenylacetic acid (4-MPAA), tetrachloroauric acid (HAuCl 4 ) and the growth solution of reducing agent L-ascorbic acid to start the growth of nanowires, wherein the molar ratio of 4-mercaptophenylacetic acid, chloroauric acid and ascorbic acid is 1:1:1. The color of the mixture gradually changed from pink to black in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com