Extraction frame with multiple groups of independent parallel functions

An extraction and functional technology, applied in the field of extraction racks, which can solve the problems of being susceptible to interference, inconvenient application, restricted structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

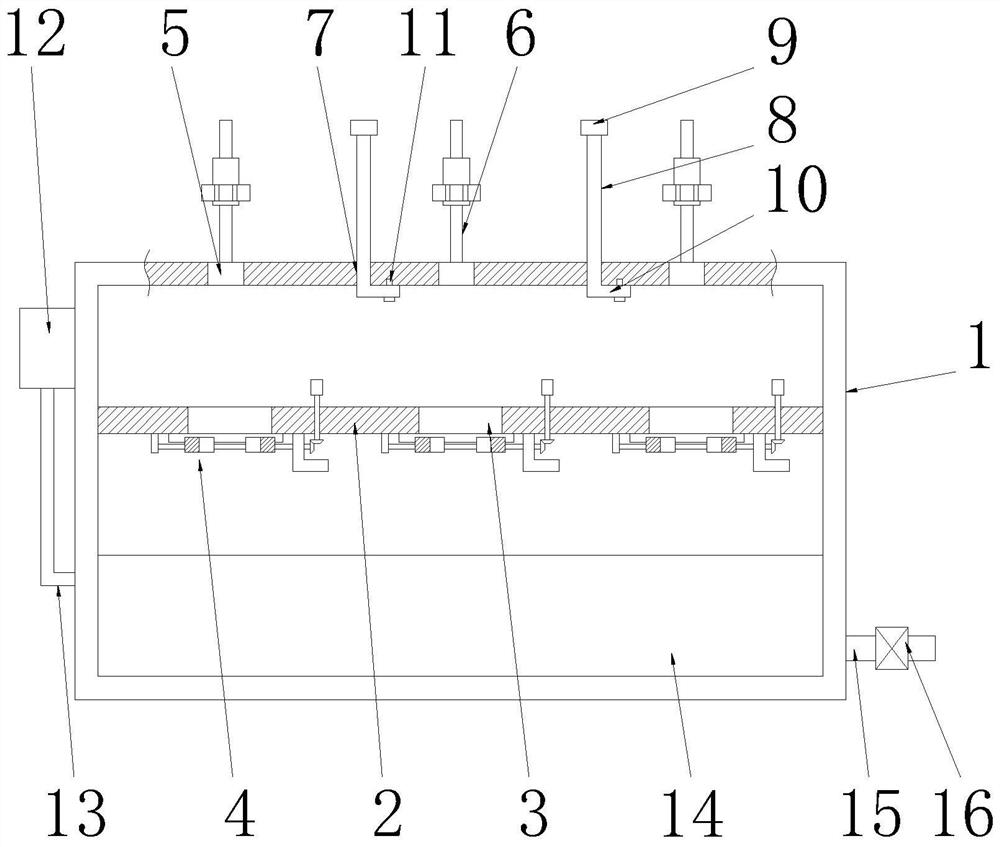

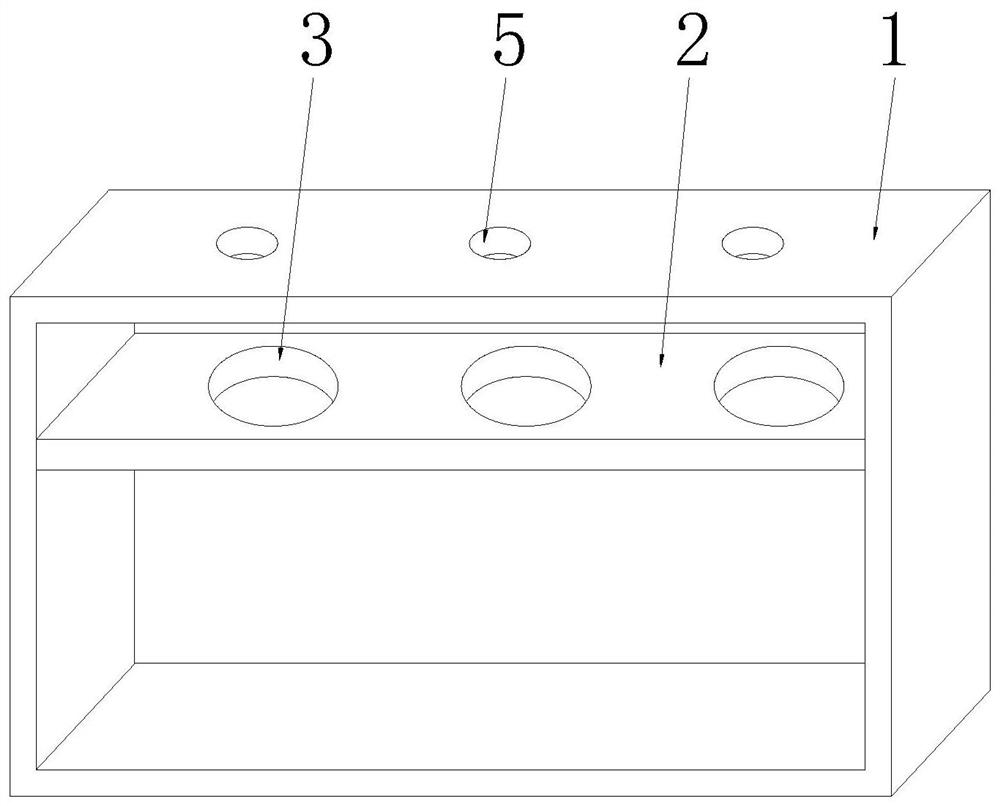

[0030] See Figure 1-2 , an extraction frame with multiple groups and independent parallel functions, comprising a seat frame 1, the seat frame 1 is a rectangular ring frame structure, the inner cavity of the seat frame 1 is provided with a supporting plate 2, and the uniform There are several supporting holes 3, and the bottom end of the supporting plate 2 is fixedly connected with a supporting clamp mechanism 4 matching with the supporting holes 3. hole 5, there is a one-to-one relationship between the drip hole 5 and the support hole 3, and the top of the mount 1 is evenly provided with a number of extraction racks 6 that match the drip hole 5, and the extraction rack There is a one-to-one correspondence relationship between 6 and the drip holes 5, and a number of partition holes 7 are evenly provided on the top wall of the mount 1, and the partition holes 7 and the drip holes 5 are interlacedly distributed. A partition 8 is slidably connected in the partition hole 7, and ...

Embodiment 2

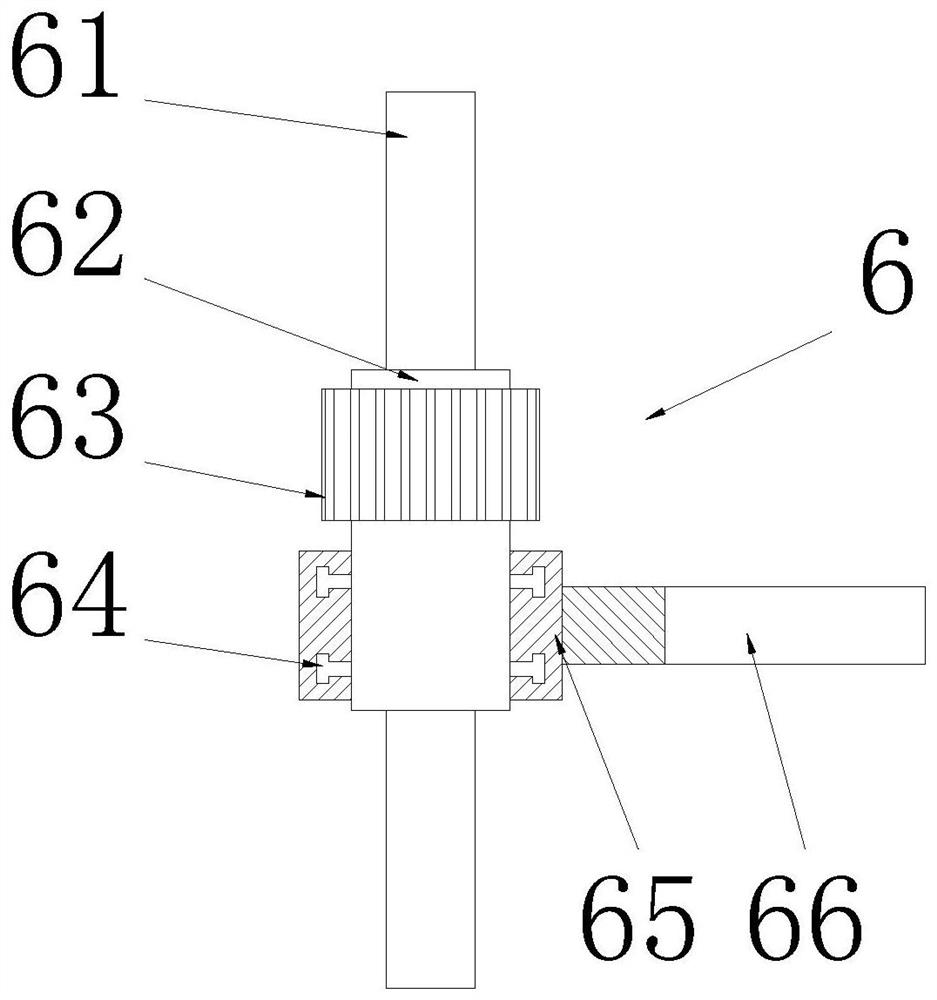

[0033] See image 3 The difference from Example 1 is that the extraction frame 6 includes a column 61, the column 61 is fixedly connected to the top of the seat frame 1, the column 61 is arranged on the rear side of the drip hole 5, and the threaded sleeve on the column 61 is provided with Lifting tube 62, the axis of the column 61 coincides with the axis of the lifting tube 62, and the outer side of the lifting tube 62 is provided with a rotary sleeve 63 and two slide rails 64, and the rotary sleeve 63 is arranged on all the slide rails 64 Above, the axis of the rotating sleeve 63 coincides with the axis of the lifting cylinder 62. The rotating sleeve 63 is made of rubber material. The slide rail 64 is a circular structure, and the slide rail 64 is a T-shaped slide rail. An angle cylinder 65 is slidably connected to the rail 64, the axis of the angle cylinder 65 coincides with the axis of the lifting cylinder 62, and the side end of the angle cylinder 65 is fixedly connected ...

Embodiment 3

[0035] See Figure 4 The difference from Embodiment 1 is that the bracket mechanism 4 includes a transmission rod 47 and two guide rails 41, the guide rails 41 are in a T-shaped structure, and the two guide rails 41 are symmetrically arranged on the bottom of the bracket hole 3. Front and rear sides, lead screw 43 is arranged between two described guide rails 41, and described lead screw 43 is arranged on the rear side of support hole 3, and one end of lead screw 43 is connected on the supporting plate 2 by bearing seat 44 rotation, and screw The other end of the bar 43 runs through the transmission frame 42 and is fixedly connected to the driven gear 45. The lead screw 43 is rotatably connected to the transmission frame 42. The transmission frame 42 is an L-shaped structure, and the transmission frame 42 is fixedly connected to the bottom end of the supporting plate 2. , the transmission rod 47 is embedded on the supporting plate 2, the transmission rod 47 is rotatably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com