Liquid-phase hydrogenation reactor and hydrogenation method thereof

A technology of liquid-phase hydrogenation and reactor, which is applied in chemical instruments and methods, hydrogenation process, hydrocarbon oil treatment, etc., and can solve problems such as severe heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

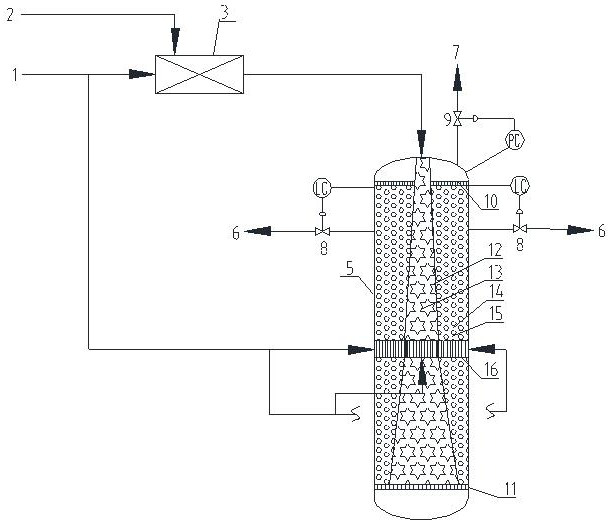

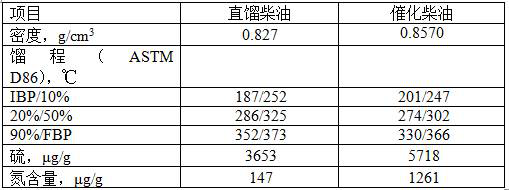

[0042] Attached figure 1In the described method, the catalyst used in the conical inner cylinder of the hydrogenation reactor is FH-40C of the Fushun Petrochemical Research Institute, and the catalyst used in the annular cavity space is FHUDS-2; the hydrogen contained in the feed of the hydrogenation reactor is Feedstock oil (the sum of fresh feedstock oil and cycle oil) is 0.23% (straight-run diesel feedstock) and 0.23% (catalytic diesel feedstock), and the amount of hydrogen supplemented in the conical inner cylinder of the hydrogenation reactor is feedstock oil (fresh feedstock oil and 0.25% (straight-run diesel feedstock) and 1.15% (catalyzed diesel feedstock) of the mass of the circulating oil, and the amount of hydrogen in the annular cavity is 0.13% of the mass of the feedstock (the sum of fresh feedstock oil and cycle oil) ( straight-run diesel feedstock) and 0.62% (catalytic diesel feedstock). The reaction conditions of the conical inner cylinder of the hydrogenation...

Embodiment 2

[0045] Attached figure 1 In the described method, the catalyst used in the conical inner cylinder of the hydrogenation reactor is FH-40C of Fushun Petrochemical Research Institute, and the catalyst used in the annular cavity is FHUDS-5; the hydrogen contained in the feed of the hydrogenation reactor is 0.22% (straight-run diesel feedstock) and 0.25% (catalyzed diesel feedstock) of the feedstock oil (the sum of fresh feedstock oil and cycle oil), and the amount of hydrogen supplemented in the conical inner cylinder of the hydrogenation reactor is feedstock oil (fresh feedstock oil and 0.26% (straight-run diesel feedstock) and 1.08% (catalyzed diesel feedstock) of the mass of circulating oil, the amount of hydrogen in the annular cavity space is 0.12% of the mass of feedstock (the sum of fresh feedstock oil and cycle oil) (straight-run diesel feedstock) and 0.65% (catalytic diesel feedstock). The reaction conditions of the conical inner cylinder of the hydrogenation reactor are...

Embodiment 3

[0048] Attached figure 1 In the method described, the catalyst used in the conical inner cylinder of the hydrogenation reactor is FHUDS-2 of the Fushun Petrochemical Research Institute, and the catalyst used in the annular cavity is FHUDS-5; the hydrogen contained in the feed of the hydrogenation reactor is used as the raw material 0.21% (straight-run diesel feedstock) and 0.23% (catalyzed diesel feedstock) of oil (the sum of fresh feedstock oil and cycle oil), and the amount of hydrogen replenishment in the conical inner cylinder of the hydrogenation reactor is feedstock oil (fresh feedstock oil and cycle oil) The sum of oil) is 0.22% (straight-run diesel feedstock) and 1.14% (catalytic diesel feedstock), and the amount of hydrogen in the annular cavity is 0.17% (straight-run diesel feedstock) of the mass of feedstock oil (the sum of fresh feedstock oil and cycle oil) (straight-run diesel feedstock) distillate diesel feedstock) and 0.58% (catalyzed diesel feedstock). The rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com