Sichuan-style pepper spicy flavor pre-fried meat product and preparation method thereof

A technology of meat products and flavor, which is applied in the field of Sichuan-style pepper-and-pepper-flavored pre-fried meat products and its preparation, which can solve the problems of not being crispy in flour coating, unstable amount of batter, and weak pepper and hemp flavor, so as to ensure stable quality Sexuality, variety of eating methods, and pure peppery taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

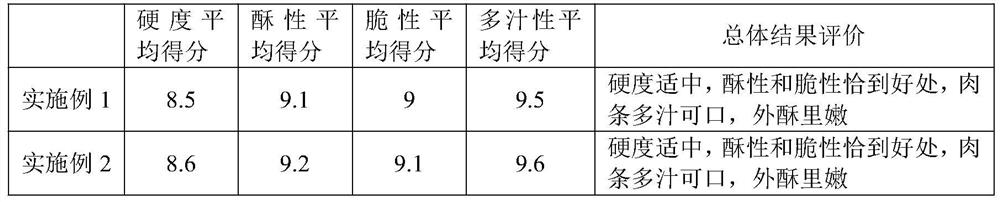

Examples

preparation example Construction

[0032] Specifically, the present invention provides a method for preparing Sichuan-style pepper and hemp flavor pre-fried meat products, comprising the following steps:

[0033] A. Pork cutting: Cut the pork with a center temperature of -1 to 4°C into pieces, and then into strips;

[0034] B. Tumbling: Add water at 0-4°C to the tumbling auxiliary material and knead, add meat strips with a temperature below 10°C, knead until the water is completely absorbed by the meat strips, and marinate;

[0035] C. Sizing: prepare the slurry by preparing whole egg liquid at 0-4°C: compound starch: prickly ash with a weight ratio of 15-18:20-23:0.2-0.22; the cured meat strips and the slurry are prepared in a weight ratio of 50 ~65:35~40 paste;

[0036] D. Frying: Heat the vegetable oil to 170-175°C, add the meat strips coated in step C, and fry.

[0037] In the step A of the present invention, pork is selected from pig hind legs, which require no pathological changes, no congestion, no for...

Embodiment 1

[0049] Cutting of pork: Choose pork hind legs without lesions, no blood, no foreign matter, and no peculiar smell. Below 25mm, the length × width × thickness of cut into meat strips is 60-90mm × 9-12mm × 7-10mm.

[0050] Tumbling: Take 0.18kg sodium tripolyphosphate, 0.32kg sodium carbonate, 0.45kg salt, 0.12kg ginger paste, 0.12kg scallion paste, 0.14kg chili powder, 0.21kg monosodium glutamate and mix to obtain rolling auxiliary materials, add 14kg 0~4℃ After adding water, the tumbling speed is 8 rpm, tumbling for 4 minutes, add 40kg of meat strips with a temperature below 10°C, and tumbling under the condition of vacuum degree below 20kPa, until the water is completely absorbed by the meat strips Afterwards, marinate for 6 hours at 0-4°C.

[0051] Sizing: Prepare compound starch: mix 16kg sweet potato starch, 3.9kg potato starch and 0.08kg baking soda. Preparation of Zanthoxylum bungeanum: Mix 0.1kg of whole Hanyuan Dahongpao Zanthoxylum bungeanum with 0.1kg of powdered M...

Embodiment 2

[0054] Cutting of pork: Choose pork hind legs without lesions, no blood, no foreign matter, and no peculiar smell. Below 25mm, the length × width × thickness of cut into meat strips is 60-90mm × 9-12mm × 7-10mm.

[0055] Tumbling: Take 0.2kg of sodium pyrophosphate, 0.35kg of sodium bicarbonate, 0.5kg of salt, 0.16kg of ginger paste, 0.16kg of green onion paste, 0.18kg of chili powder, and 0.25kg of monosodium glutamate. After adding water, the tumbling speed is 12 rpm, tumbling for 6 minutes, adding 50kg of meat strips with a temperature below 10°C, and tumbling under the condition that the vacuum degree is below 20kPa until the water is completely absorbed by the meat strips Afterwards, marinate at 0-4°C for 18 hours.

[0056] Sizing: Prepare compound starch: mix 18kg sweet potato starch, 4.1kg potato starch and 0.1kg baking soda. Preparation of Zanthoxylum bungeanum: Mix 0.11kg of whole Hanyuan Dahongpao Zanthoxylum bungeanum with 0.11kg of powdered Maowen Dahongpao Zanth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com