Stator and permanent magnet motor

A permanent magnet motor and stator technology, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of low winding efficiency and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

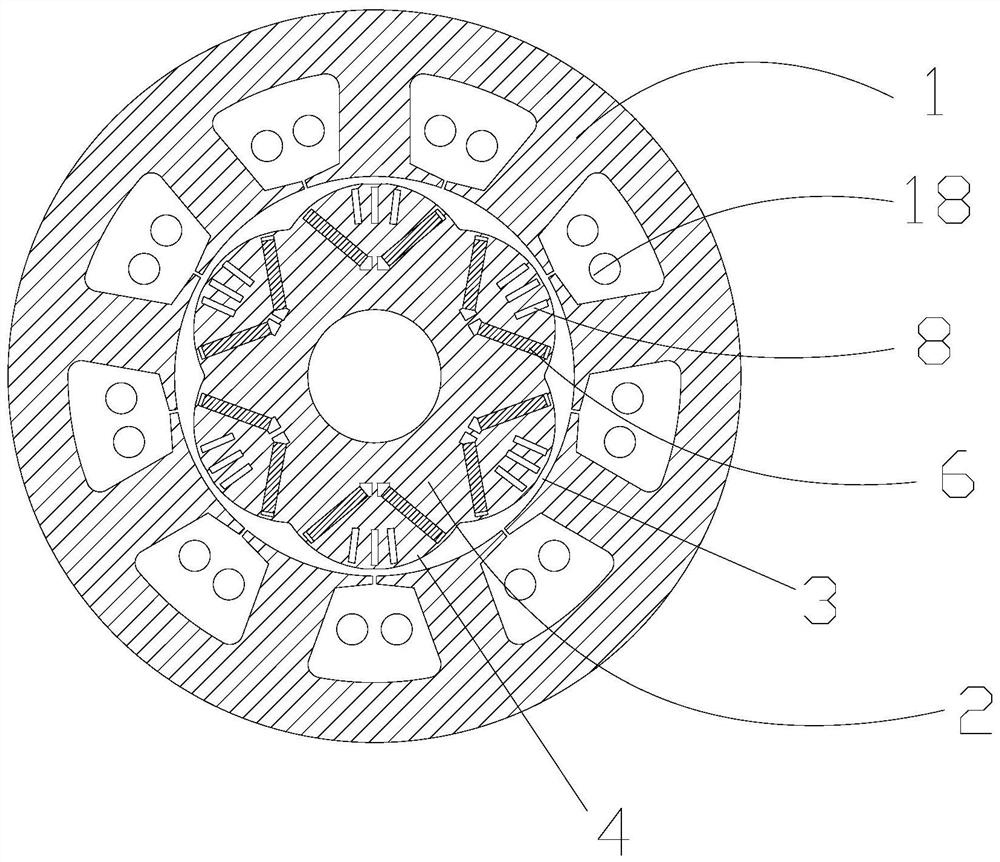

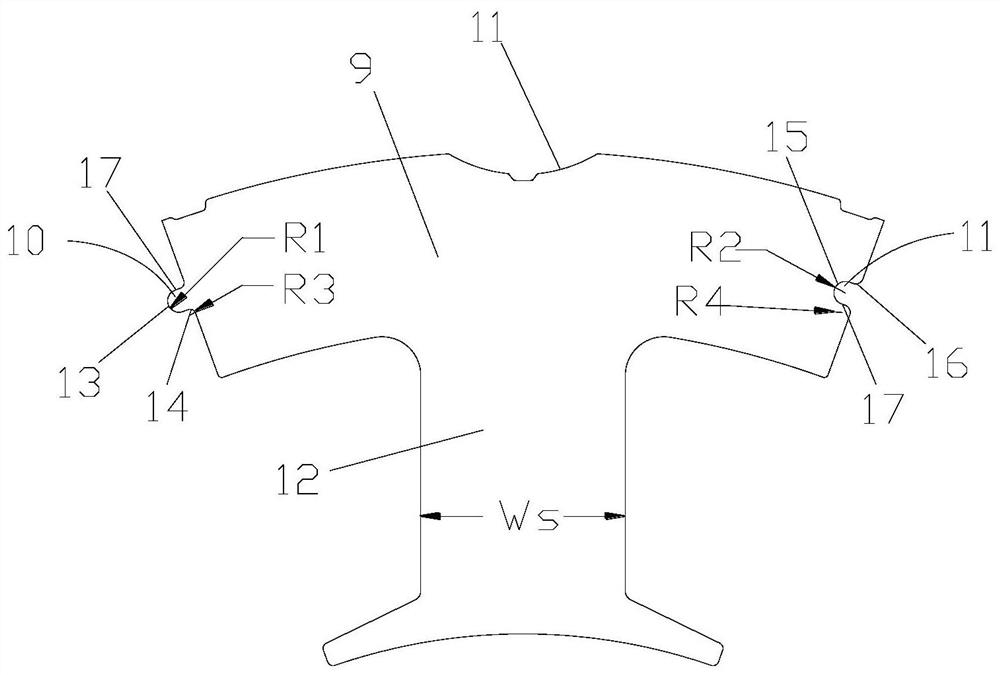

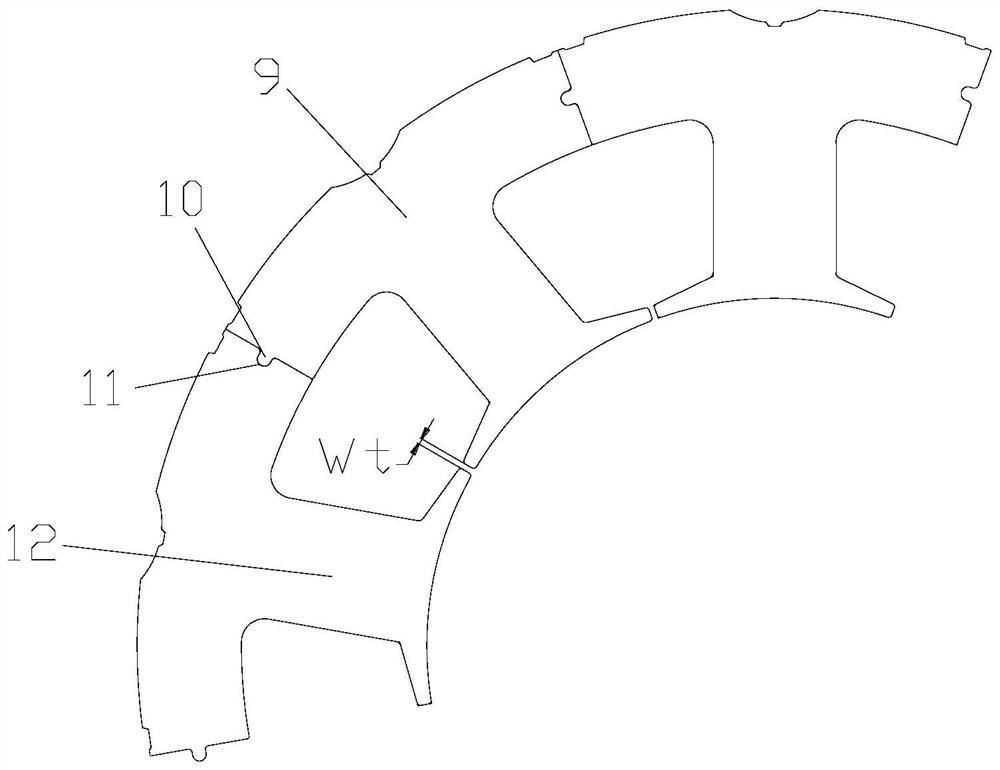

[0035] see in conjunction Figure 1 to Figure 10 As shown, according to the embodiment of the present application, the stator includes a plurality of iron core segments 9, and the plurality of iron core segments 9 are arranged in sequence along the circumferential direction. Each iron core segment 9 includes protrusions 10 and grooves 11, and the protrusions 10 is located on the first side surface of the iron core block 9 along the circumferential direction, the groove 11 is located on the second side surface of the iron core block 9 along the circumferential direction, the protrusion 10 matches the groove 11, each The protrusions 10 of the iron core segments 9 are embedded in the grooves 11 of the adjacent iron core segments 9 .

[0036] In this embodiment, the stator adopts a segmented structure. After winding each iron core segment 9, all the iron core segments 9 can be assembled into an integral stator. Since each iron core segment 9 They are all individually wound, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com