Heat dissipation device for SYQT intelligent dynamic liquid resistance speed regulator and using method

A technology of liquid resistance governor and heat sink, applied in liquid resistors, resistors, resistor parts and other directions, can solve the problem of unsatisfactory cooling effect, increased cabinet temperature of starting cabinet, and cabinets with high temperature Internal problems, to achieve the effect of maintaining work efficiency, reducing internal temperature and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

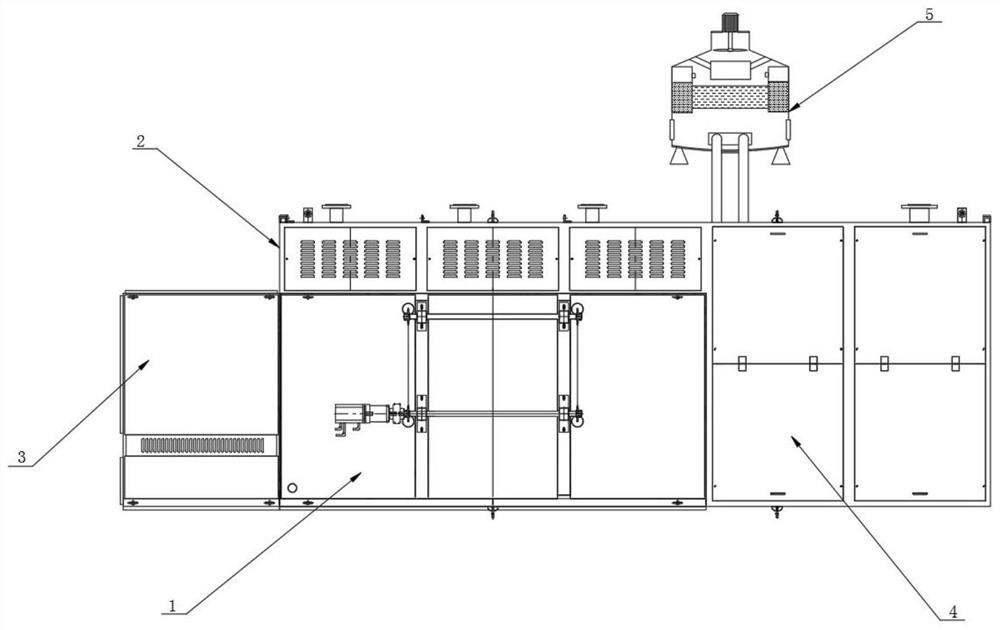

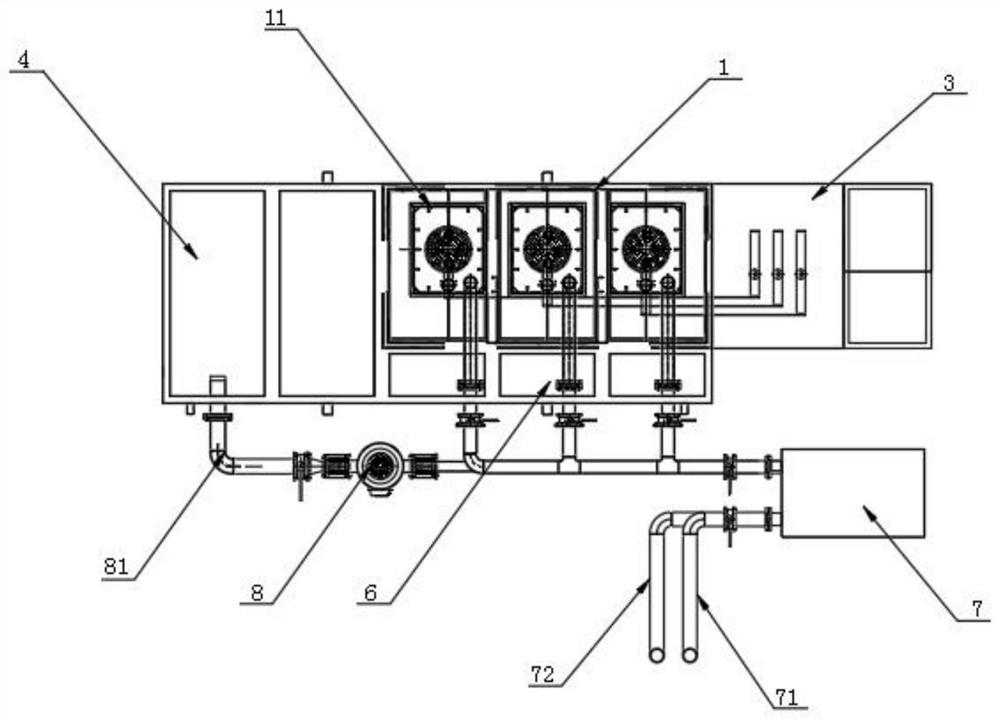

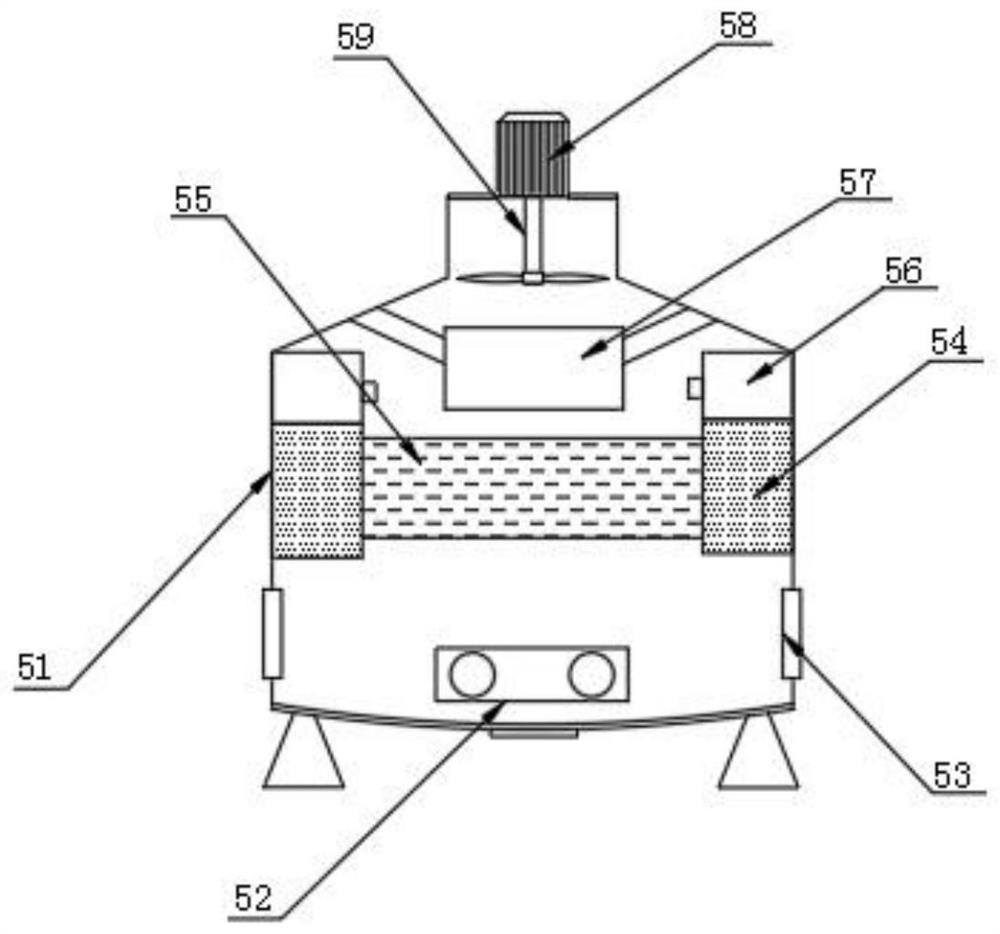

[0028] refer to Figure 1-4 A cooling device for a SYQT intelligent dynamic liquid resistance speed controller and a method of use shown include a resistance speed control cabinet 1, the number of the resistance speed control cabinets 1 is set to be multiple, and the front surface of the resistance speed control cabinet 1 There is a heat dissipation plate 2, a shorting cabinet 3 is provided on one side of the resistance speed control cabinet 1, a control cabinet 4 is provided on the other side of the resistance speed control cabinet 1, and a cooling tower is connected to the outside of the top of the resistance speed control cabinet 1 5. An lye storage box 6 is provided on the rear surface of the resistance speed control cabinet 1, and a plate heat exchanger 7 is connected to the outside of the lye storage box 6, and a water pump 8 is provided at the bottom of the lye storage box 6, so that The plate heat exchanger 7 communicates with the water pump 8;

[0029] The cooling to...

Embodiment 2

[0033]The surface of the mounting plate 11 is evenly provided with heat dissipation holes, the surface of the heat dissipation plate 2 is evenly provided with hinged windows, and the inside of the heat dissipation plate 2 is provided with a heat dissipation fan, and the heat dissipation fan is arranged on the top of the inner wall of the resistance speed control cabinet 1 .

[0034] The lye storage box 6 is fixedly arranged on the rear side surface of the resistance speed control cabinet 1, and the top of the lye storage tank 6 is connected with an lye return pipe 61, and the lye return pipe 61 is circularly arranged in the resistance speed control cabinet 1 The surface of the inner wall penetrates through the resistance speed control cabinet 1 and extends to the outside. The outside of the lye storage tank 6 is connected with an lye connecting pipe 62 , and the lye connecting pipe 62 is connected with the plate heat exchanger 7 .

[0035] The outer bottom of the plate heat exc...

Embodiment 3

[0038] The present invention also provides a method for using the cooling device of the SYQT intelligent dynamic liquid resistance governor, the specific steps are:

[0039] Step 1: When the equipment is working normally, the cooling fan on the inner wall of the cooling plate 2 works and accelerates the air flow inside the resistance speed control cabinet 1 to dissipate heat through the hinged window and cooling holes;

[0040] Step 2: The lye storage tank 6 outside the resistance speed control cabinet 1 is filled with lye to cool down the resistance speed control cabinet 1, and the cooled lye is transferred to the plate heat exchanger 7 for heat exchange and then passes through the lye transmission pipe in turn 72 and lye return pipe 61 are transported back to the lye storage tank 6 to carry out circulation heat dissipation and cooling, and the lye is transferred back to the lye storage tank 6 after being circulated and cooled by the resistance speed control cabinet 1 inwall d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com