Multi-stage drying device for LED production

A technology of drying device and mounting frame, applied in drying, drying machine, lighting device and other directions, can solve the problems of LED influence, single-sided drying effect, single speed and temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

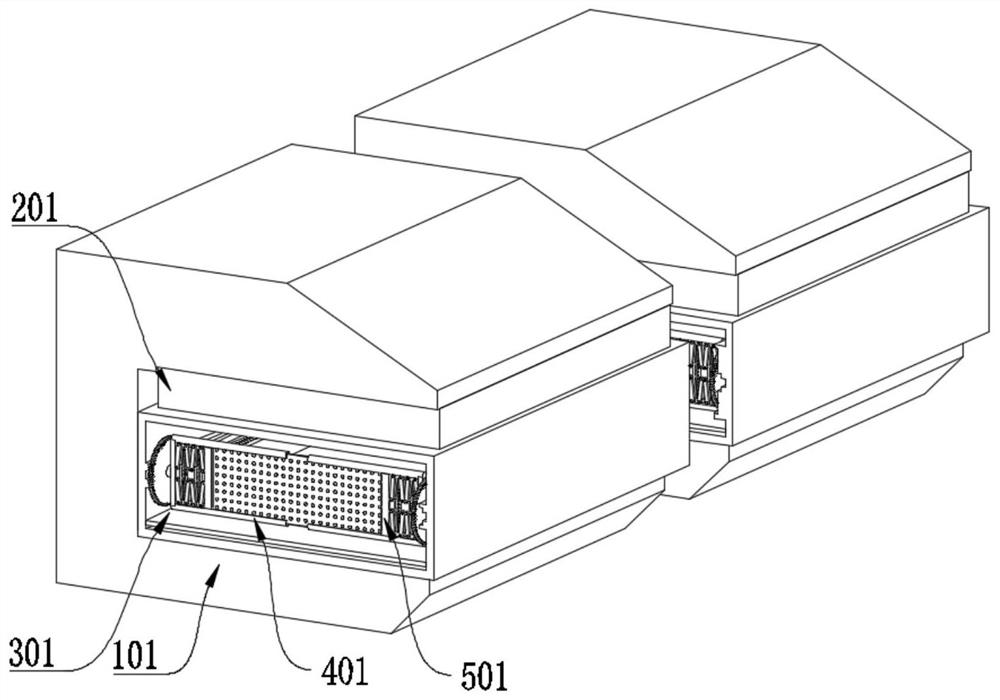

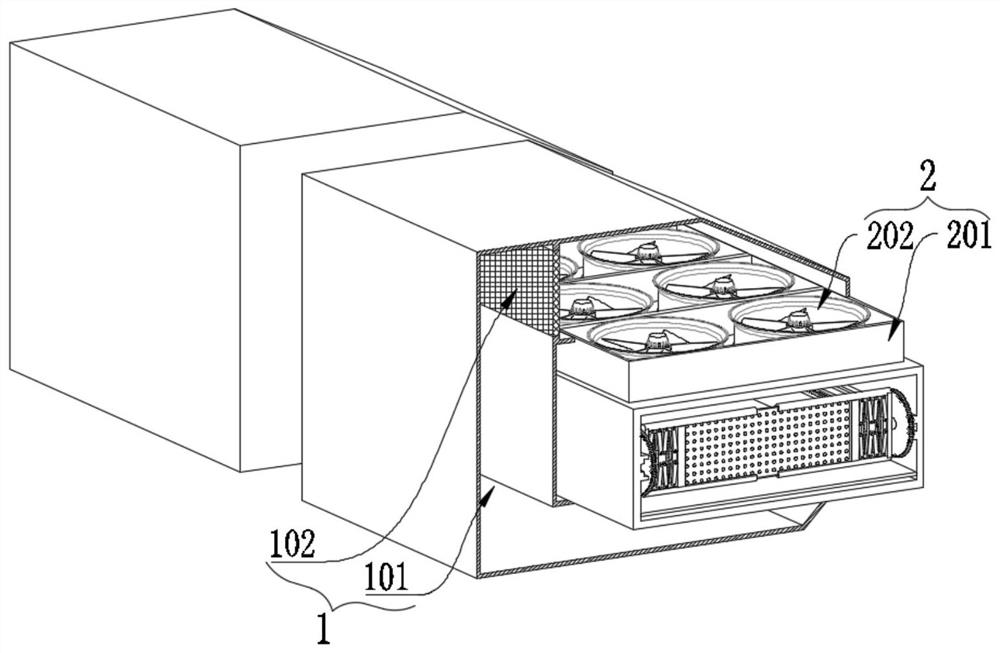

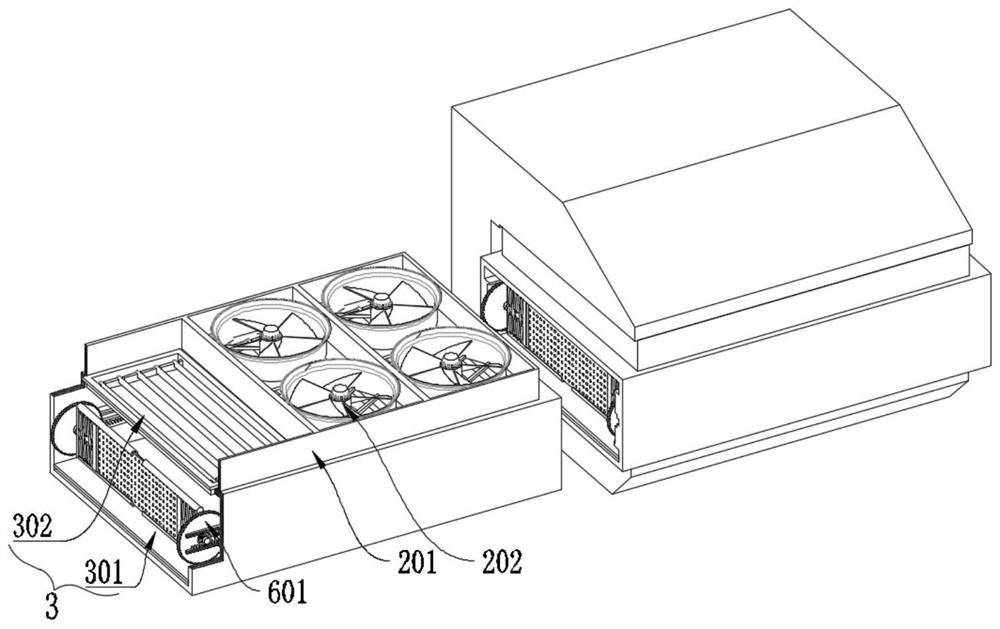

[0034] as attached figure 1 to attach Figure 7 Shown:

[0035] The present invention provides a multi-stage drying device for LED production, comprising a pipeline structure 1; a blower structure 2 is installed on the pipeline structure 1; a filter structure 3 is installed at the lower end of the blower structure 2; a clamp structure 4 is installed at the position of the filter structure 3; An auxiliary structure 5 is installed at the outer end of the fixture structure 4 ; a transmission structure 6 is fixed at the outermost end of the fixture structure 4 .

[0036] Among them, the pipeline structure 1 also includes an air duct 101 and a filter plate 102. The air duct 101 is installed at the outer end of the drying device, and the overall structure of the air duct 101 is C-shaped. The upper end and the lower end of the air duct 101 are connected to each other. The upper end of the air duct 101 is vertically installed with a filter plate 102, the air duct 101 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com