Tunnel construction method

A technology for tunnel construction and material transportation, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of inconvenient transfer of ballast materials, multi-ballast materials, and easy falling of ballast materials to the middle part to be excavated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

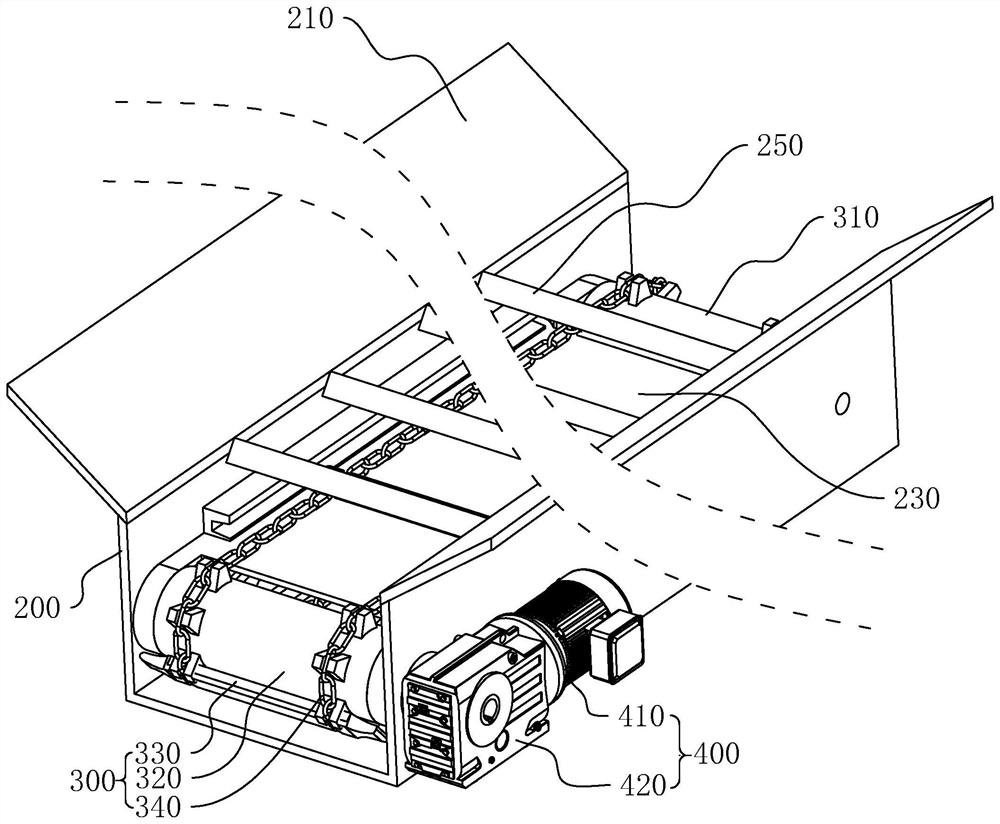

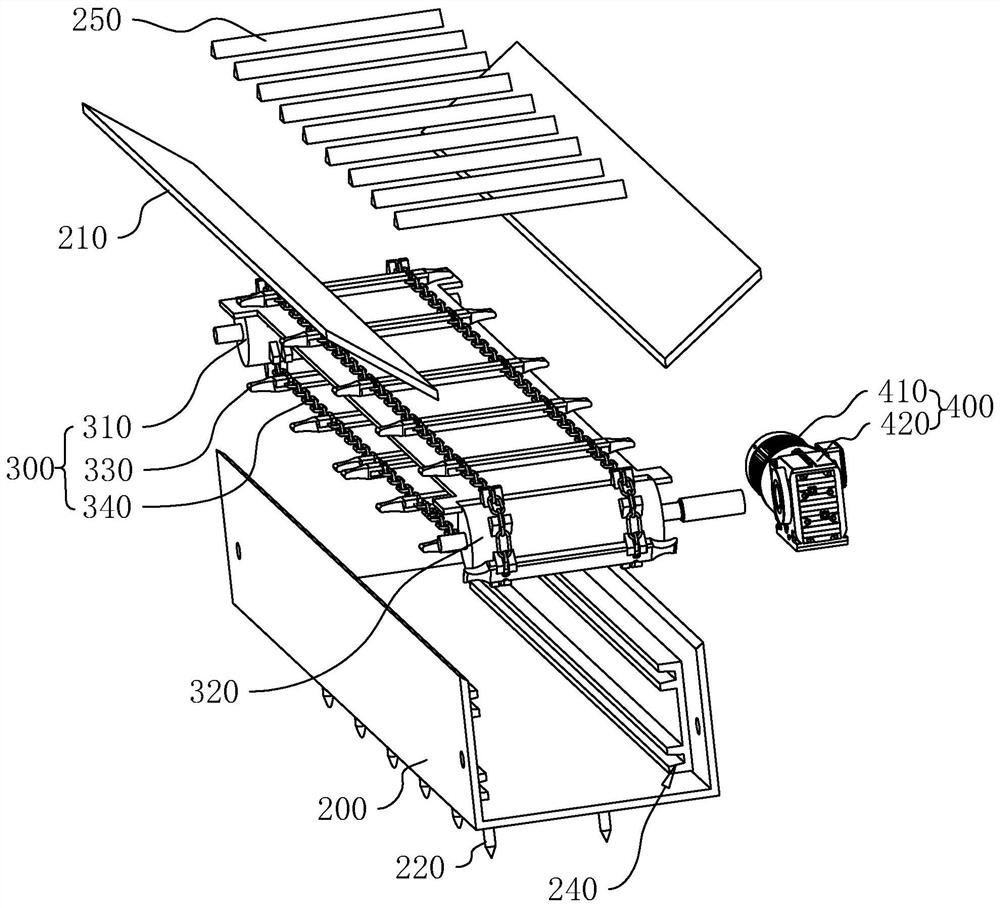

[0034] The following is attached Figure 1-3 The application is described in further detail.

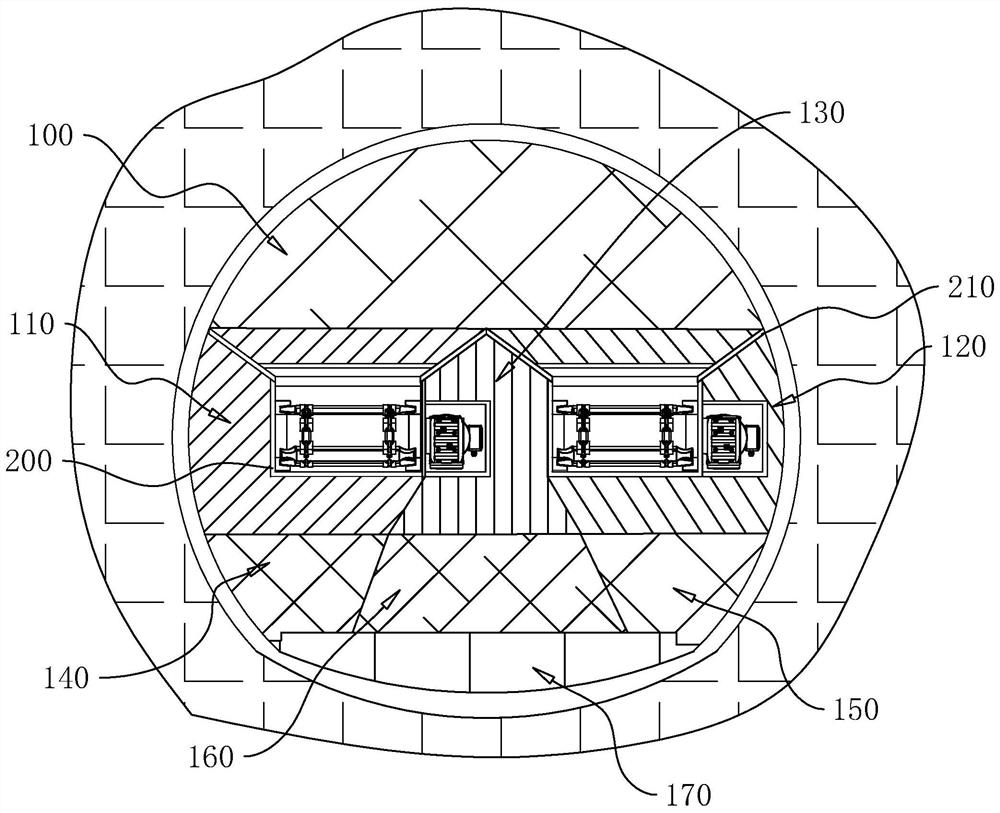

[0035] The embodiment of the present application discloses a tunnel construction method. refer to figure 1, the entire section to be excavated is divided into four parts: the upper part to be excavated 100, the middle part to be excavated 180, the lower part to be excavated 190 and the bottom part to be excavated 170, wherein the middle part to be excavated 180 is divided into the middle left area 110, The middle right area 120 and the central middle area 130, and the middle part to be excavated 190 are also divided into the lower left area 140, the lower right area 150 and the lower middle area 160, and excavating these four parts by step method, Wherein, the upper portion to be excavated 100 is about 3 to 5 m ahead of the middle portion to be excavated 180, the middle portion to be excavated 180 is ahead of the middle portion to be excavated 190 by about 3 to 5 m, the middle port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com