Annular detachable rubber probe sidewall contact device

A pusher and rubber technology, which is applied in measurement, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as limited volume, unstable support foundation, insufficient friction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

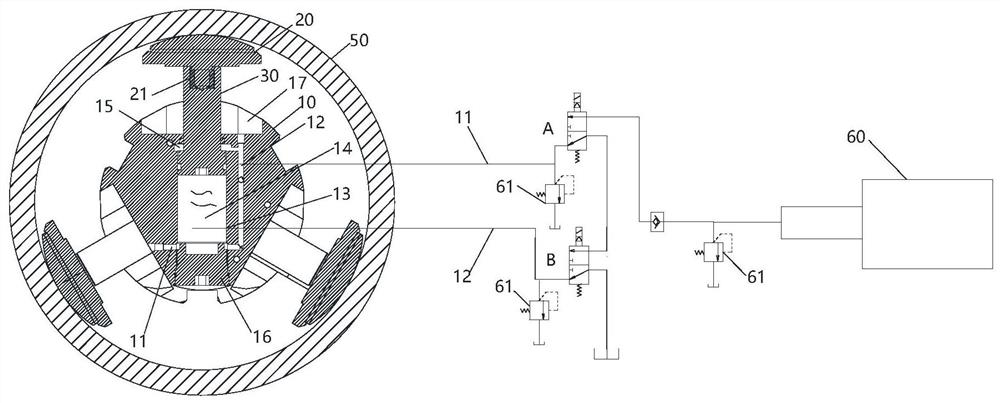

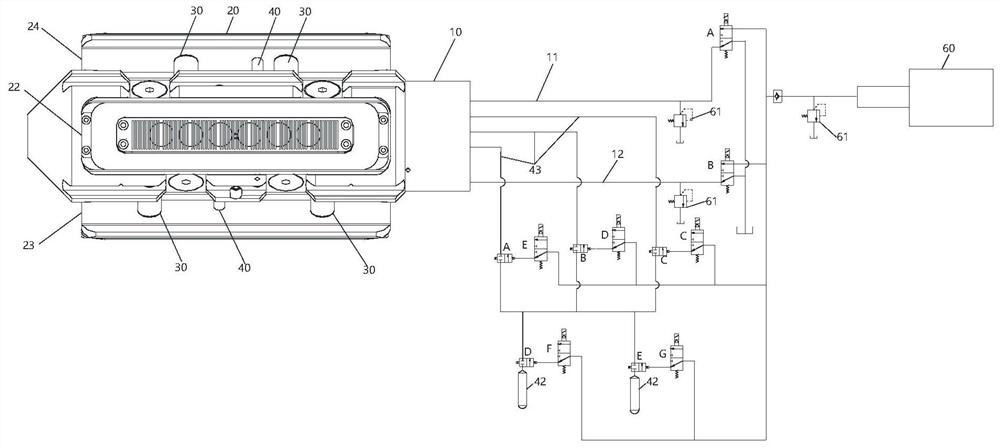

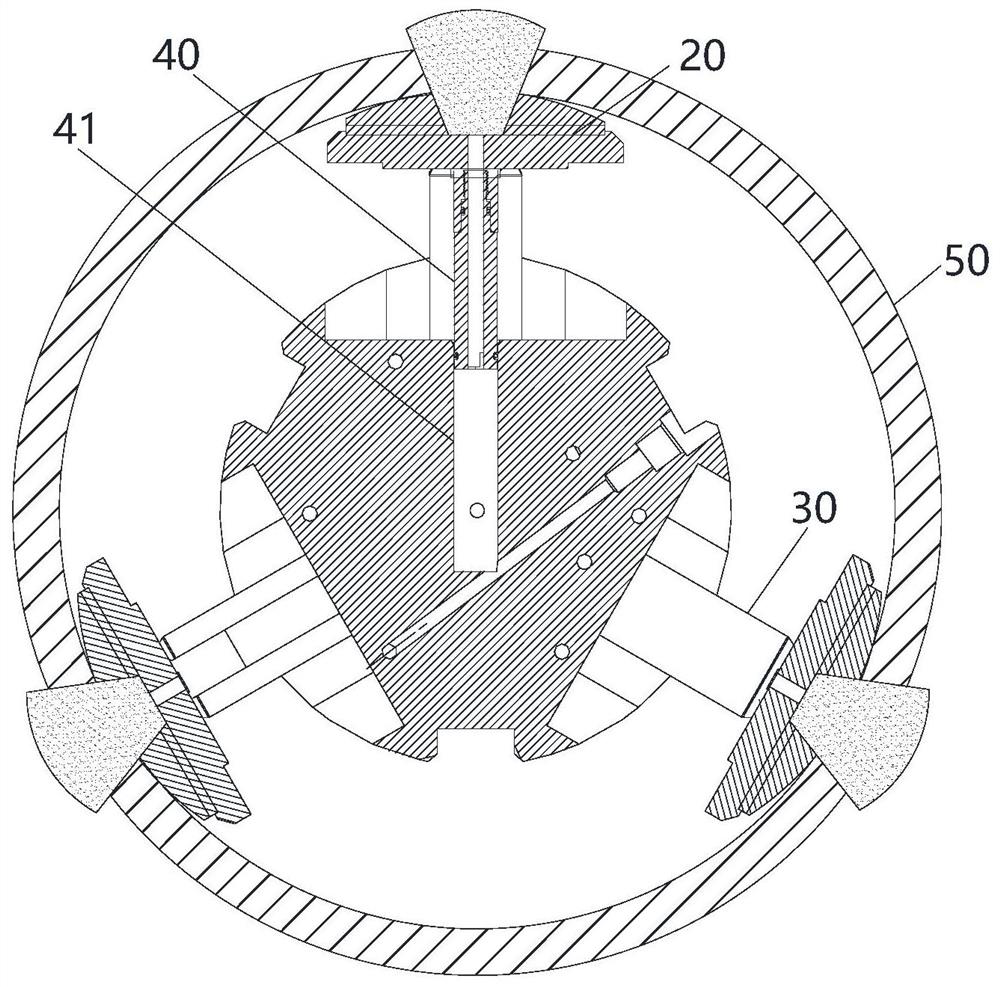

[0024] Such as figure 1 As shown, in one embodiment of the present invention, an annular detachable rubber probe pusher is disclosed, and the pusher can be connected with the main base, so that the pusher can realize supporting stay downhole. A specific pusher includes a body 10 , a pusher arm and a sampling tube 40 .

[0025] The machine body 10 is columnar, and it can be connected with the forward end of the main body through one end, so as to be an independent detachable part, such as figure 2 As shown, a high-pressure output oil circuit 11 and a high-pressure contraction oil circuit 12 are arranged inside the body 10, and the high-pressure output oil circuit 11 and the high-pressure contraction oil circuit 12 are respectively used to transport high-pressure hydraulic oil to drive the push arm to realize stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com