Warping device for cloth weaving

A technology of warp beams and sliders, which is applied in warping machines, textiles, papermaking, and tool manufacturing, and can solve problems such as insufficient pressure, affecting the finishing effect of warp yarns, and insufficient pressure on warp beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

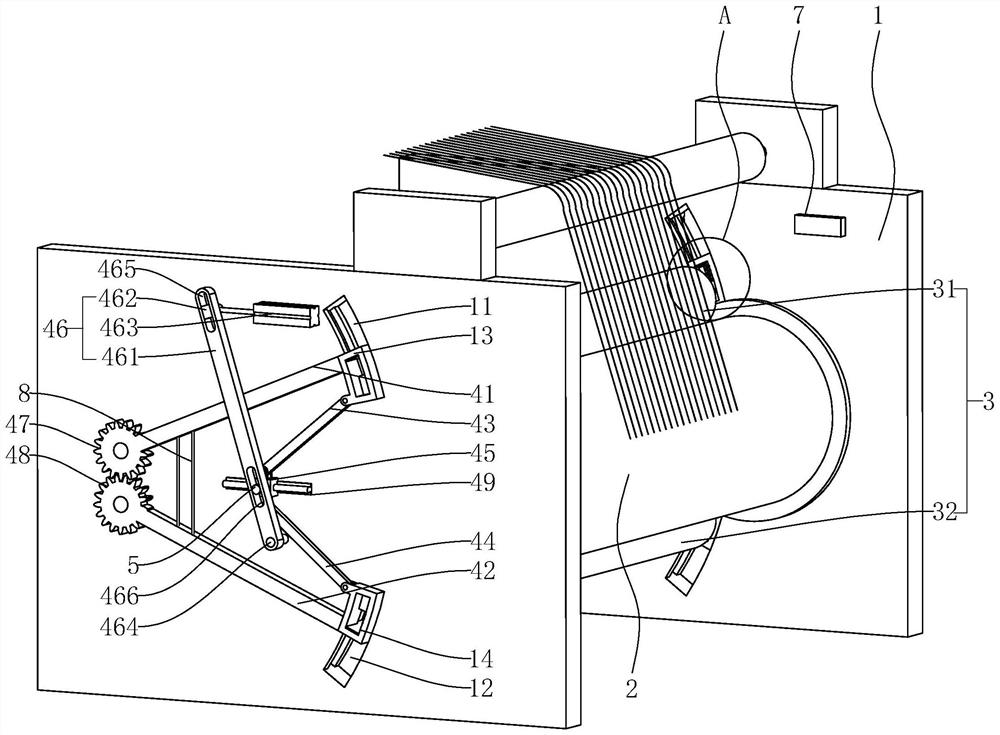

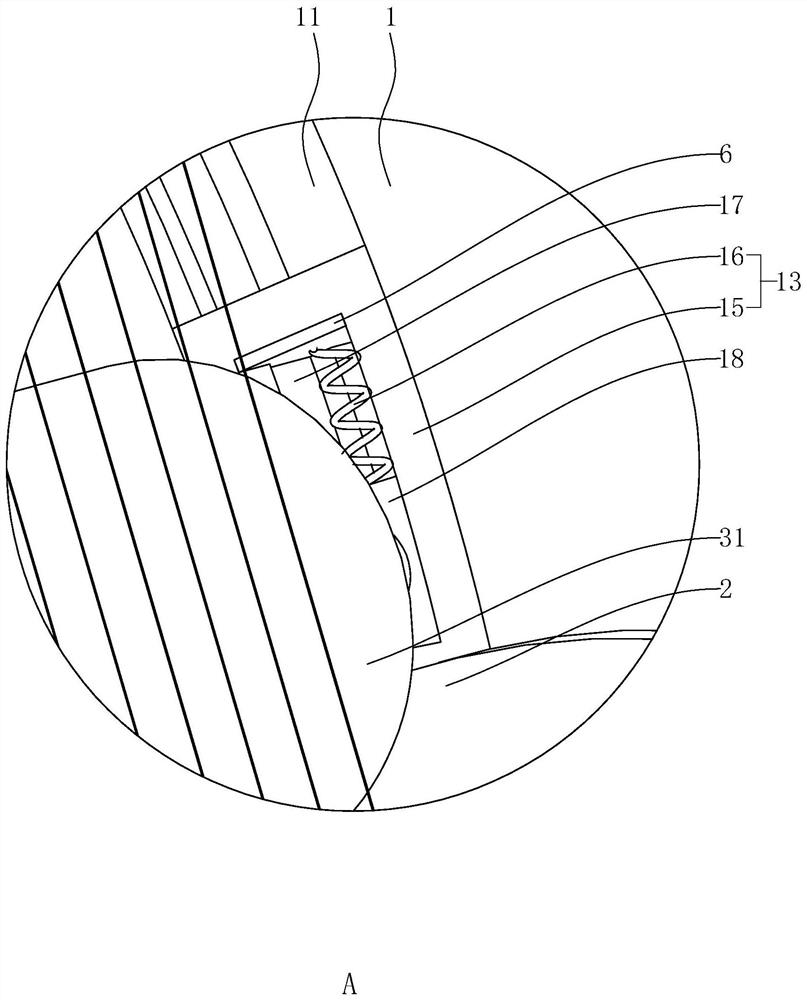

[0034] The following is attached Figure 1-2 The application is described in further detail.

[0035] The embodiment of the present application discloses a warping device for weaving cloth.

[0036] refer to figure 1 , the warping device used for weaving includes a frame 1, a warp beam 2 and a pressure roller 3, wherein the two ends of the warp beam 2 are respectively rotatably worn on both sides of the frame 1, and are preset in the positive Under the action of the driving motor, it rotates around its own axis to wind up a certain number of warp yarns to make preliminary preparations for weaving.

[0037] In this embodiment, the pressure roller 3 includes an upper pressure roller 31 and a lower pressure roller 32 arranged in parallel with each other at intervals, wherein the upper pressure roller 31 and the lower pressure roller 32 have the same size and shape, and the upper pressure roller 31 and the lower pressure roller 32 have the same size and shape. The rollers 32 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com