Polyolefin elastomer waterproof roll and preparation method thereof

A polyolefin elastomer and waterproofing membrane technology, which is applied in the direction of roofing, roofing, and roof covering using flexible materials, can solve the problems of aging resistance, weather resistance, cracking resistance and insufficient weldability, and achieve excellent resistance. The effect of aging, broad market prospects and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

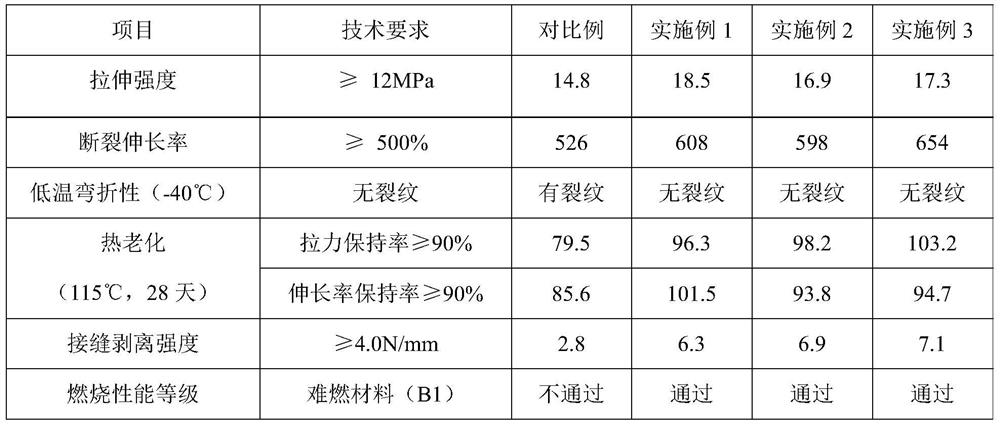

Examples

Embodiment 1

[0049] Get 60 parts of calcium carbonate (4000 mesh heavy calcium), 15 parts of antioxidant (brand, B225), 10 parts of anti-ultraviolet agent (brand, UV770), 10 parts of flame retardant (brand, Saytex102), 5 parts of rutile titanium White powder (brand, R105), mixed on a high-speed mixer for 15 minutes, put the above-mentioned uniformly mixed materials into a twin-screw extruder, set the temperature of the twin-screw extruder to 190°C, and plasticize, draw, and granulate Get loaded multifunctional additives.

[0050] Get 49.4 parts of ethylene-propylene rubber (brand, 6950), 25 parts of polyolefin elastomer (brand, POE 2300), 25 parts of polypropylene (brand, PP 7032), 0.5 part of initiator (L101), 0.1 part of auxiliary crosslinking agent (TMPTMA), mixed on a high-speed mixer for 15 minutes, put the above-mentioned homogeneously mixed materials into a twin-screw extruder, set the temperature of the twin-screw extruder to 190 ° C, and obtain waterproof rolls through screw plast...

Embodiment 2

[0053] Take 60 parts of elastomer (brand, CA60A), 15 parts of antioxidant (brand, B225), 10 parts of anti-ultraviolet agent (brand, UV770), 10 parts of flame retardant (brand, Saytex102), 5 parts of rutile titanium dioxide (brand name, R105), mixed on a high-speed mixer for 15 minutes, put the above-mentioned homogeneously mixed materials into a twin-screw extruder, set the temperature of the twin-screw extruder to 190 ° C, and obtained through screw plasticization, traction, and granulation Loaded multifunctional additive.

[0054] Get 49.6 parts of ethylene-propylene rubber (brand, 6950), 15 parts of elastomer (brand, CA10A), 35 parts of polypropylene (brand, PP7032), 0.3 part of initiator (L101), 0.1 part of auxiliary crosslinking agent (TMPTMA), Mix on a high-speed mixer for 15 minutes, put the above-mentioned homogeneously mixed materials into a twin-screw extruder, set the temperature of the twin-screw extruder at 190°C, and obtain polyolefin for waterproof membranes thr...

Embodiment 3

[0057] Get 60 parts of calcium carbonate (4000 mesh heavy calcium), 15 parts of antioxidant (brand, B225), 10 parts of anti-ultraviolet agent (brand, UV770), 10 parts of flame retardant (brand, Saytex102), 5 parts of rutile titanium dioxide (brand name, R105), mixed on a high-speed mixer for 15 minutes, put the above-mentioned homogeneously mixed materials into a twin-screw extruder, set the temperature of the twin-screw extruder to 190 ° C, and obtained through screw plasticization, traction, and granulation Loaded multifunctional additive.

[0058] Get 39.3 parts of ethylene-propylene rubber (brand, 6950), 25 parts of elastomer (brand, CA10A), 35 parts of polypropylene (brand, PP7032), 0.4 part of initiator (L101), 0.3 part of auxiliary crosslinking agent (TMPTMA), Mix on a high-speed mixer for 15 minutes, put the above-mentioned homogeneously mixed materials into a twin-screw extruder, set the temperature of the twin-screw extruder at 190°C, and obtain polyolefin for waterp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com