A device for accurately picking and placing a special-shaped gluing bucket from an incubator

A technology for incubators and rubber barrels, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the deformation of special-shaped thin-walled rubber barrels, cannot meet the requirements of accurate identification, grasping, throwing, coating automation and high efficiency, and increase the labor intensity of operators, etc. problem, to achieve the effect of safe transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

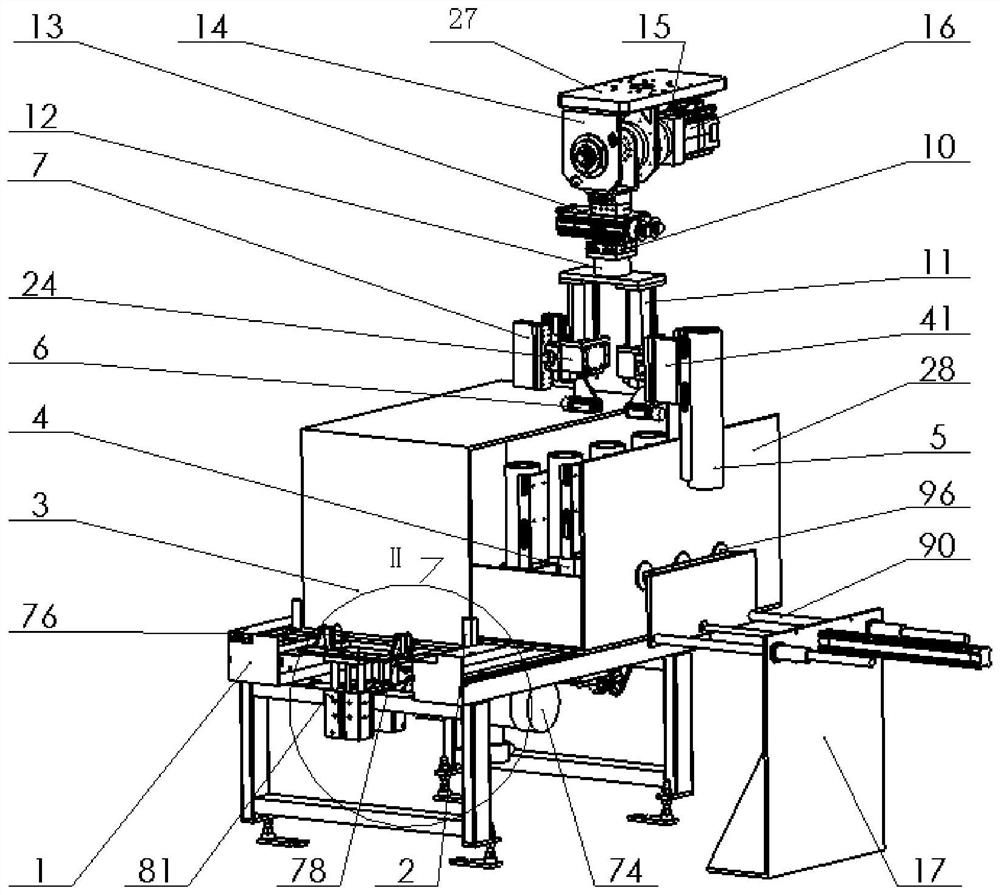

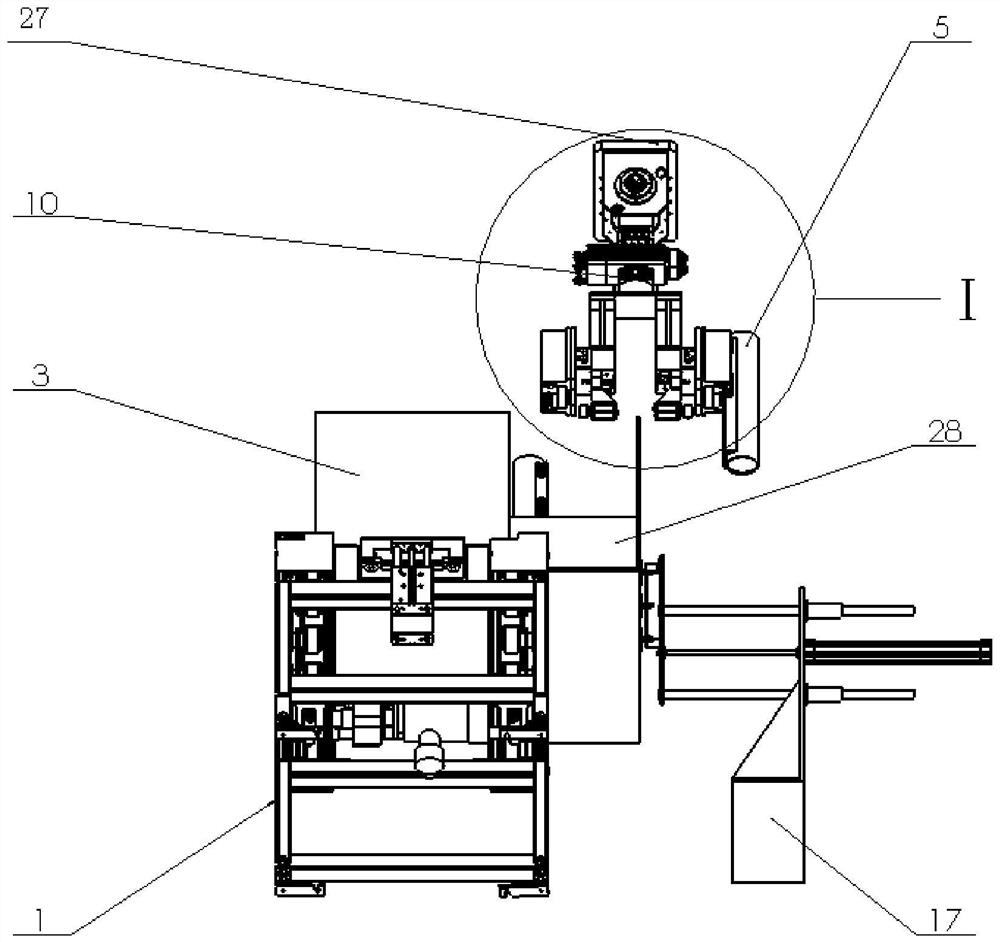

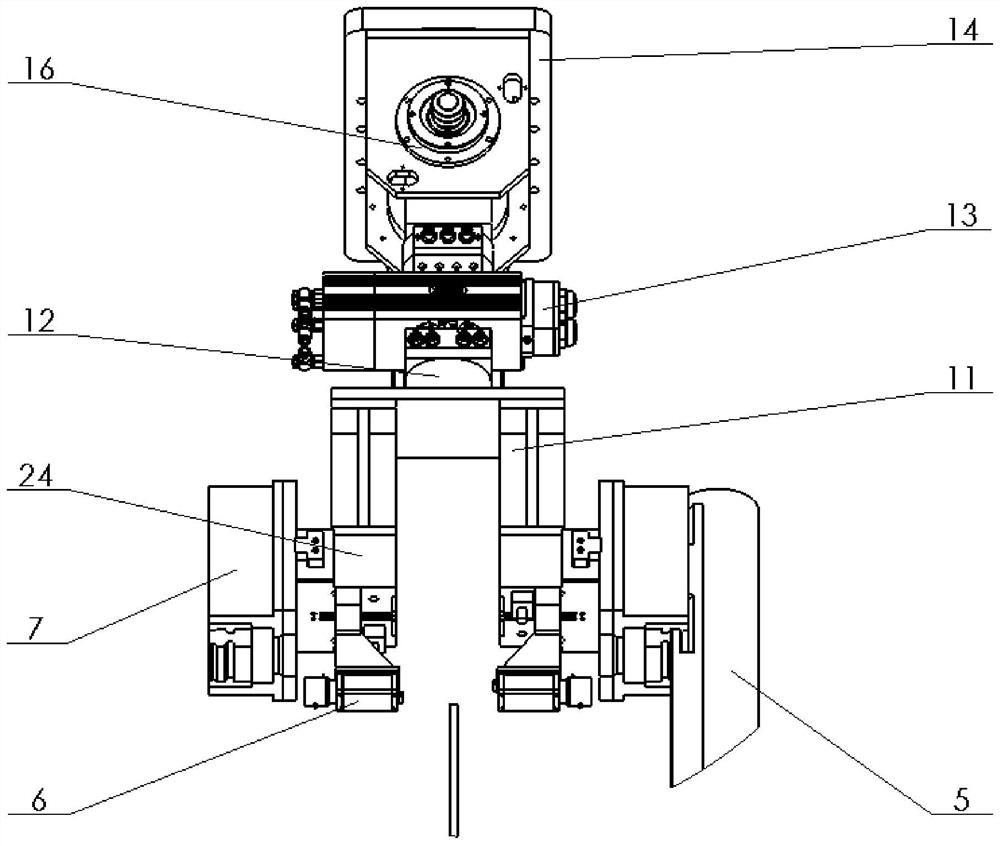

[0032] Such as figure 1 As shown, a device for accurately picking and placing special-shaped throwing glue buckets from the incubator. It includes: a line body support conveying unit 1, a pallet conveying device 2, a rubber bucket moisturizing unit 3, a gripper unit 7, an opening and closing mechanism unit 17, a rotating seat 11 and an overturning unit 14. Wherein, the line support conveying unit 1 is placed at the bottom to support the transmission; the unit 3 for moisturizing the rubber bucket is placed at the upper end to maintain the humidity in the box and carry the workpiece; the rotating seat 11 and the turning unit 14 Placed at one end of the rubber bucket moisturizing unit 3, it can realize the functions of precise positioning, grasping,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com