Automobile lightweight door frame assembly

A lightweight, door technology, applied to vehicle parts, doors, transportation and packaging, etc., can solve problems such as poor safety factor of anti-collision, falling off of anti-collision frame, and stabbing of drivers and passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

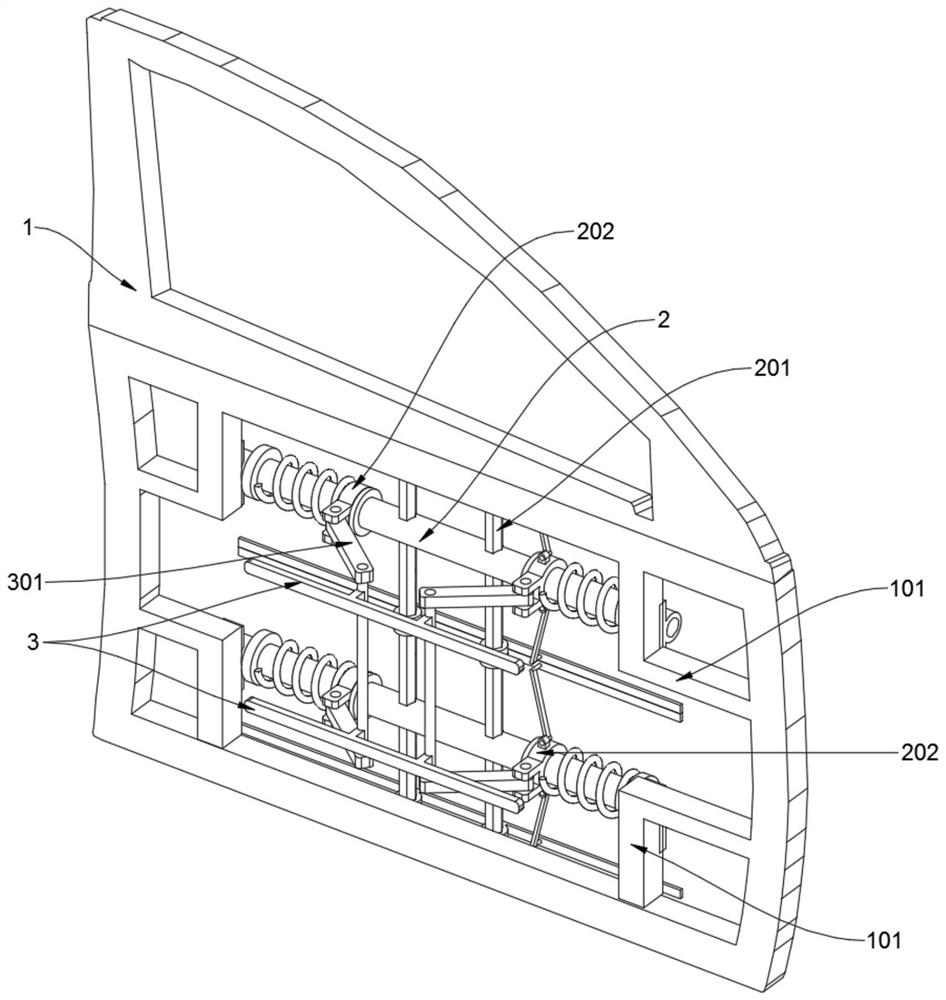

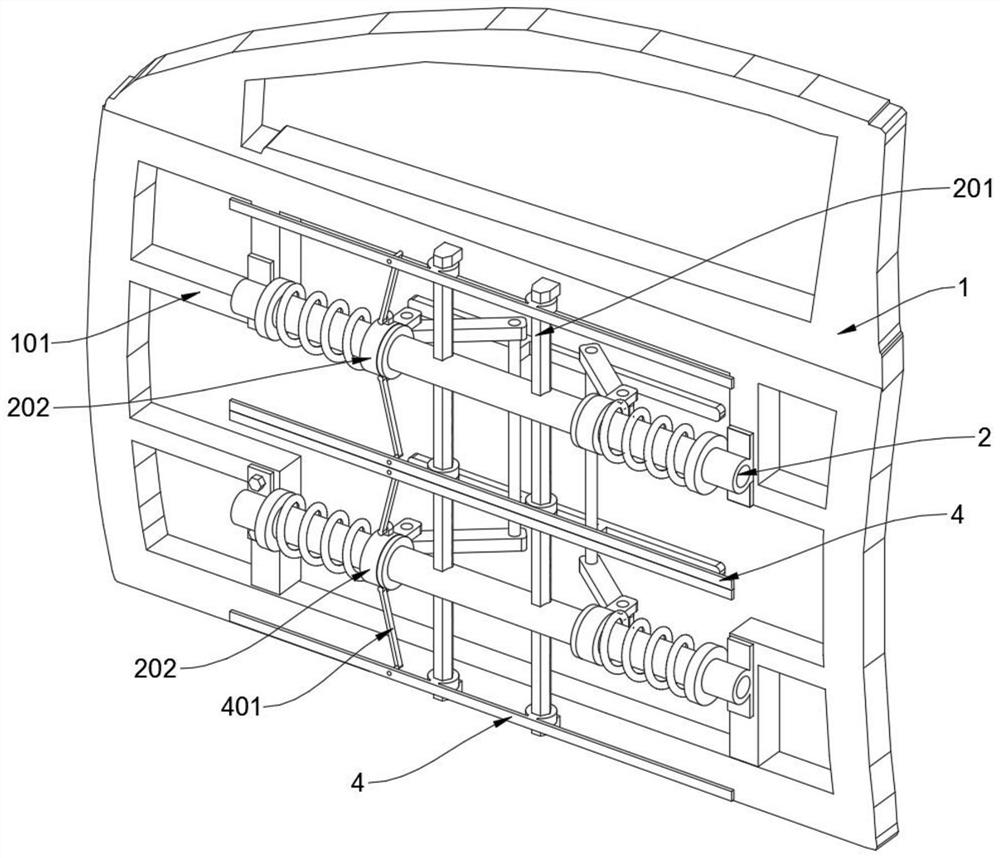

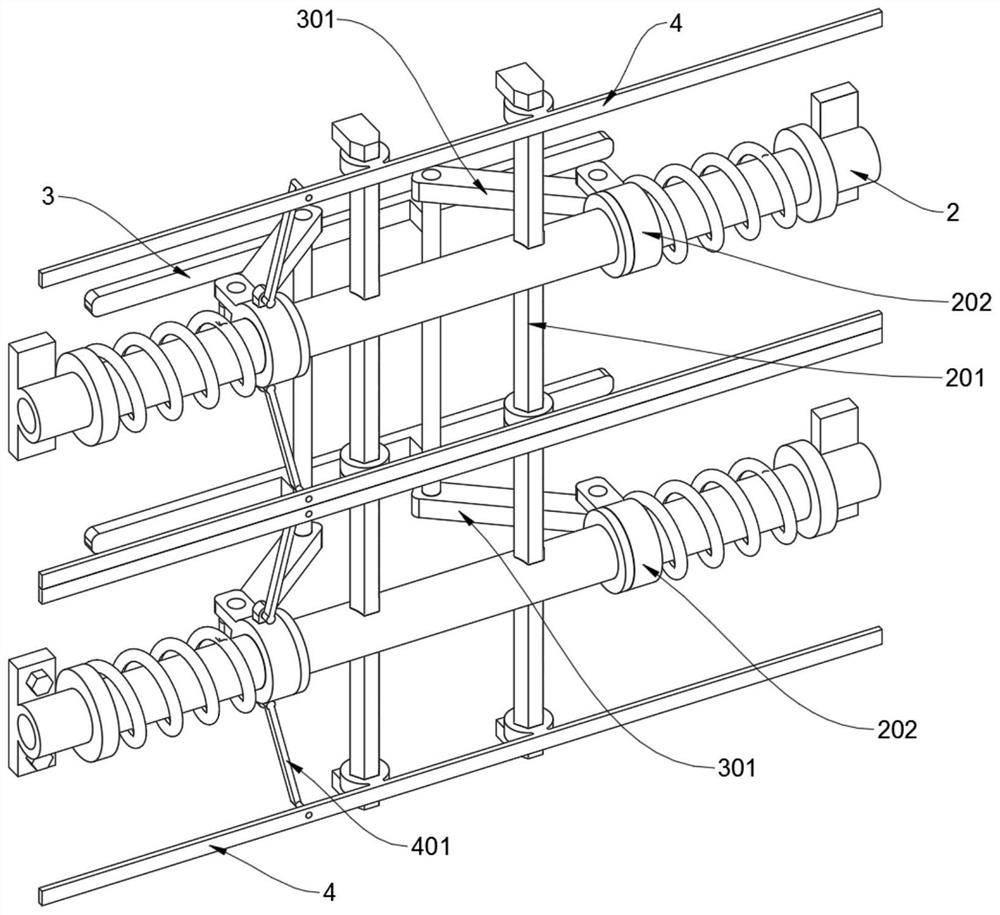

[0030] see Figure 1 to Figure 7 , an embodiment provided by the present invention: an automobile lightweight door frame assembly, including a door frame 1, the door frame 1 includes an L-shaped mounting seat 101, the upper half of the door frame 1 is a triangular arc structure, and the lower half is a rectangular shape. The arc-shaped bending structure on both sides, and the lower half of the door frame 1 is symmetrically stamped with four L-shaped mounting seats 101; the four L-shaped mounting seats 101 are symmetrically welded and fixed with two cross-bracing steel pipes 2, and the two cross-bracing steel pipes The length of 2 is two-thirds of the width of the doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com