Sleeve positioning double-face machining device

A technology of double-sided processing and sleeve, applied in the field of mechanical processing, can solve the problems of increasing processing cost, increasing clamping correction time, cutting, and difficulty in alignment and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

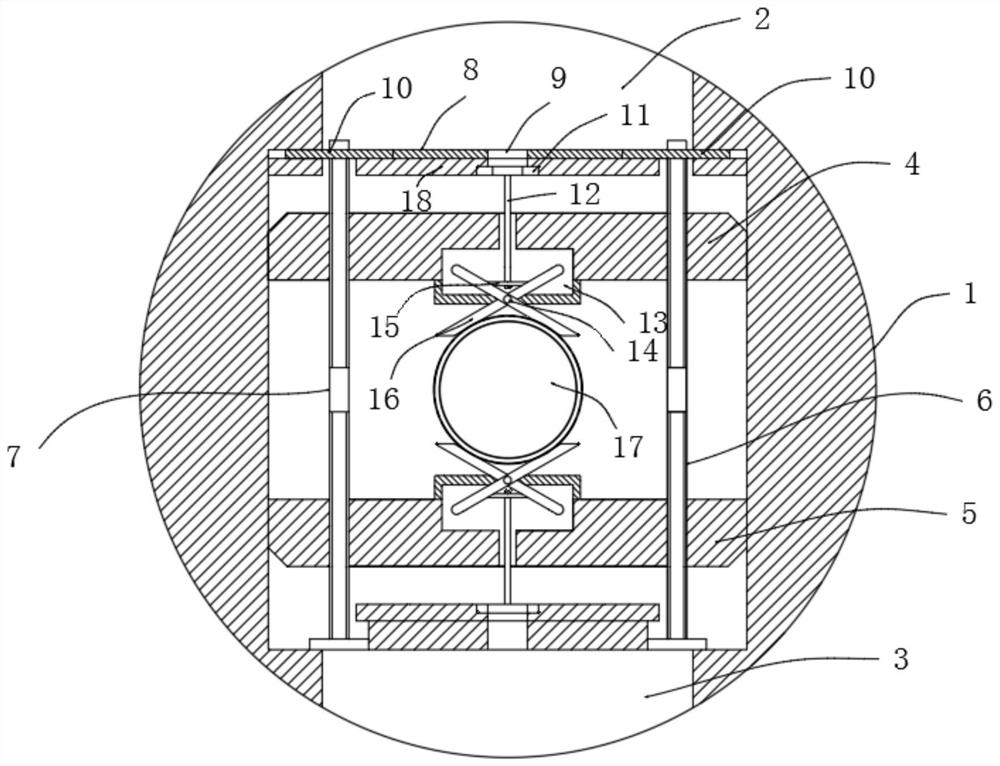

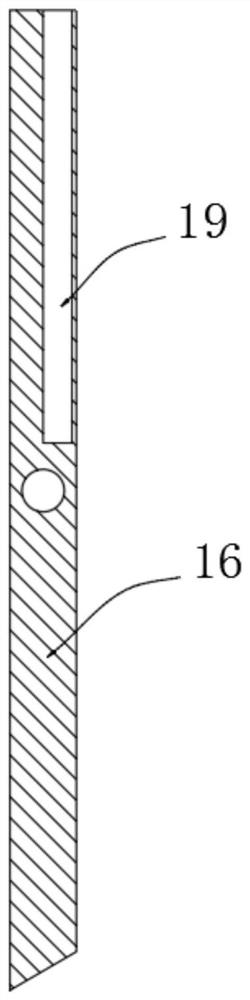

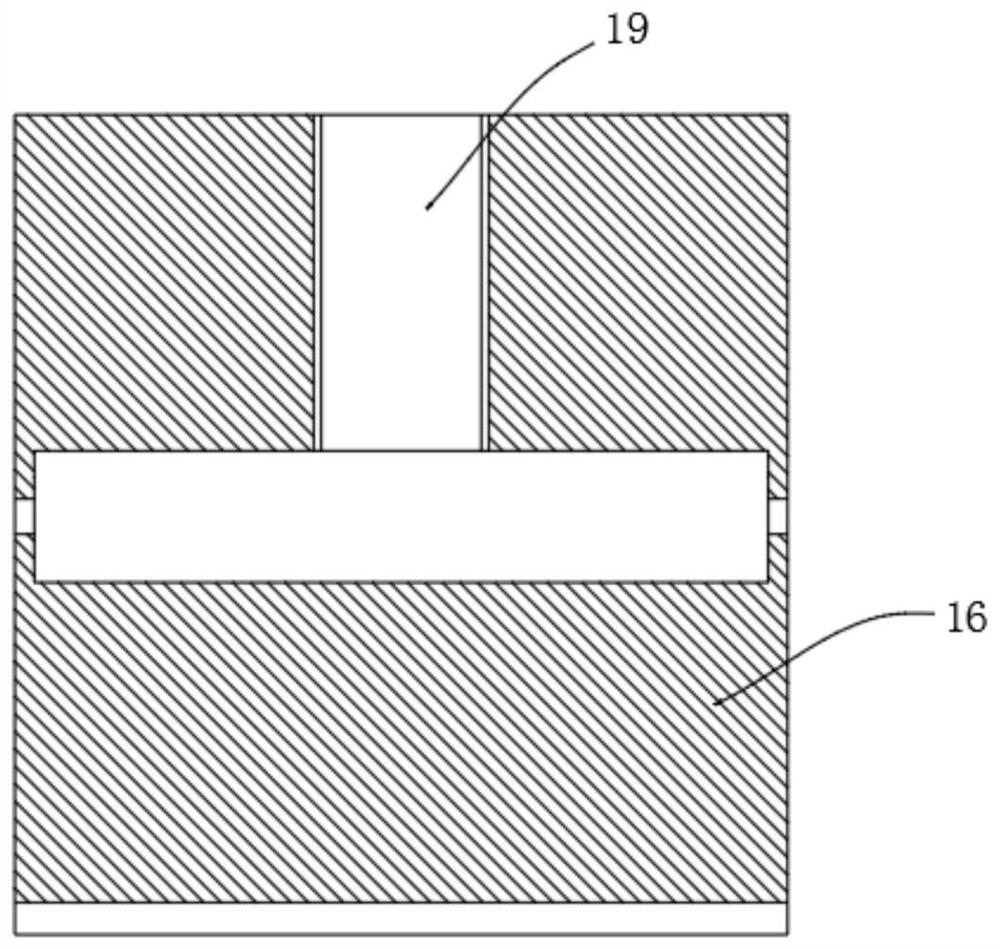

[0021] Such as figure 1 , figure 2 and image 3 As shown, a sleeve positioning double-sided processing device includes a sleeve member 1, the end surface of the sleeve member 1 is provided with a hole that runs through itself, and the inside of the sleeve member 1 is provided with a limited cavity. The upper and lower end surfaces of the sleeve member 1 are provided with adjustment notches, the defined cavity communicates with the adjustment notch, and the inside of the sleeve member 1 is provided with limiting sliders, and the number of the limiting sliders is an even number pair , and distributed symmetrically up and down, the inside of the sleeve member 1 is connected with an adjustment device, and the adjustment device can adjust the distance between the upper and lower relative limit sliders, and the limit sliders engage the workpiece 17 .

[0022] Restricting notches are provided on the opposite end faces of the upper and lower restricting sliders, and the regulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com