3D printing method of metal ceramic composite material

A 3D printing and composite material technology, applied in the field of 3D printing of metal-ceramic composite materials, can solve problems such as difficult printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

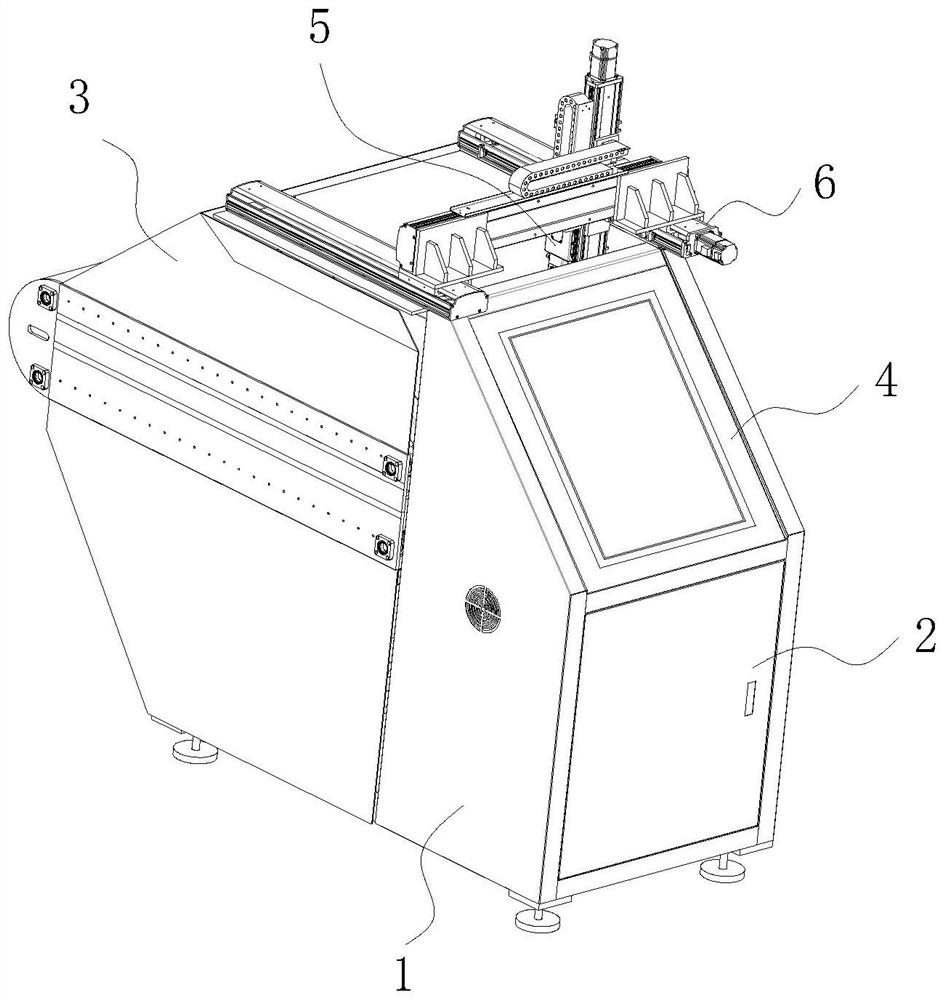

Image

Examples

Embodiment 1

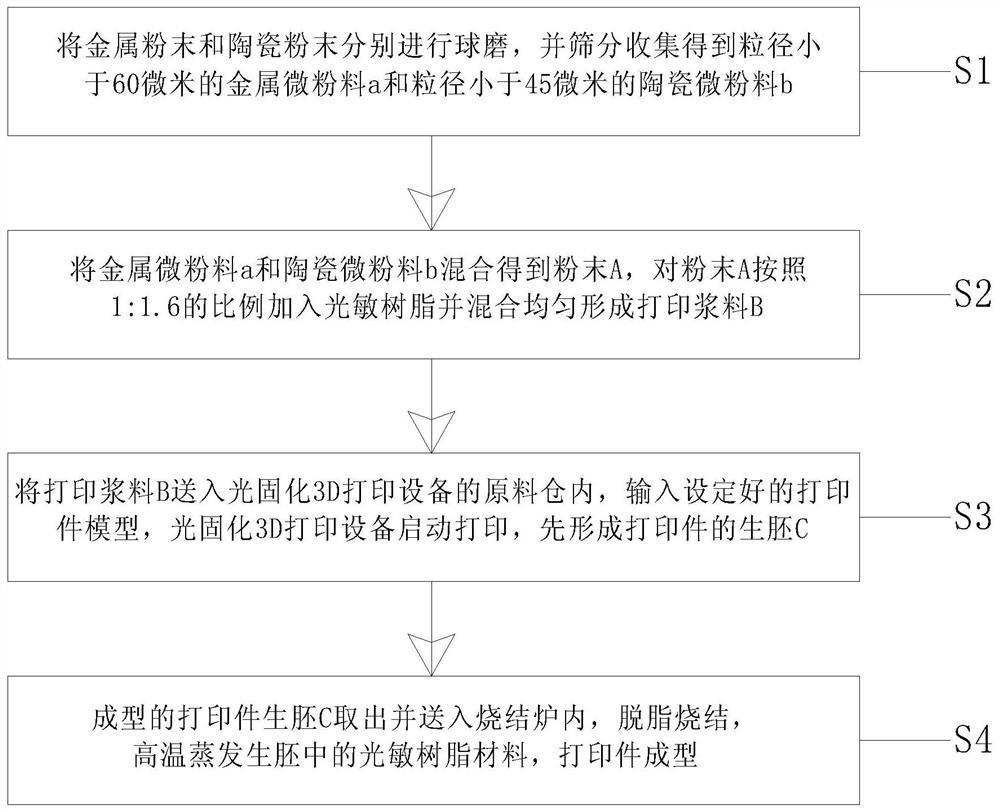

[0030] A 3D printing method for a metal-ceramic composite material, comprising the following steps:

[0031] S1. Ball milling the metal powder and the ceramic powder respectively, and sieving and collecting metal micropowder material a with a particle size of less than 60 microns and ceramic micropowder material b with a particle size of less than 45 microns;

[0032] S2, mixing 60 parts by weight of metal micropowder a and 40 parts by weight of ceramic micropowder b to obtain powder A, adding photosensitive resin to powder A according to the ratio of 1:1.6 and mixing uniformly to form printing paste B;

[0033] Among them, the photosensitive resin is formulated by 14% oligomer, 50% photoinitiator and 36% diluent;

[0034] S3. Send the printing slurry B into the raw material warehouse of the light-curing 3D printing device, input the set print model, the light-curing 3D printing device starts printing, and first form the green embryo C of the printed part;

[0035] S4. The fo...

Embodiment 2

[0041] A 3D printing method for a metal-ceramic composite material, comprising the following steps:

[0042] S1. Ball milling the metal powder and the ceramic powder respectively, and sieving and collecting metal micropowder material a with a particle size of less than 60 microns and ceramic micropowder material b with a particle size of less than 45 microns;

[0043] S2, mixing 65 parts by weight of metal micropowder a and 35 parts by weight of ceramic micropowder b to obtain powder A, adding photosensitive resin to powder A according to the ratio of 1:1.6 and mixing uniformly to form printing paste B;

[0044] Among them, the photosensitive resin is formulated from 16% oligomer, 54% photoinitiator and 30% diluent;

[0045] S3. Send the printing slurry B into the raw material warehouse of the light-curing 3D printing device, input the set print model, the light-curing 3D printing device starts printing, and first form the green embryo C of the printed part;

[0046] S4. The ...

Embodiment 3

[0052] A 3D printing method for a metal-ceramic composite material, comprising the following steps:

[0053] S1. Ball milling the metal powder and the ceramic powder respectively, and sieving and collecting metal micropowder material a with a particle size of less than 60 microns and ceramic micropowder material b with a particle size of less than 45 microns;

[0054]S2. Mix 70 parts by weight of metal micropowder a and 30 parts by weight of ceramic micropowder b to obtain powder A, add photosensitive resin to powder A according to the ratio of 1:1.6 and mix uniformly to form printing paste B;

[0055] Among them, the photosensitive resin is formulated by 18% oligomer, 60% photoinitiator and 22% diluent;

[0056] S3. Send the printing slurry B into the raw material warehouse of the light-curing 3D printing device, input the set print model, the light-curing 3D printing device starts printing, and first form the green embryo C of the printed part;

[0057] S4. The formed green...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com