Bidirectional sisal hemp harvester

A harvester, two-way technology, applied in the field of two-way sisal harvester, can solve the problems of low degree of automation, lack of flexibility, labor, etc., and achieve the effect of high automation level, improved harvesting efficiency, stable and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with specific embodiments.

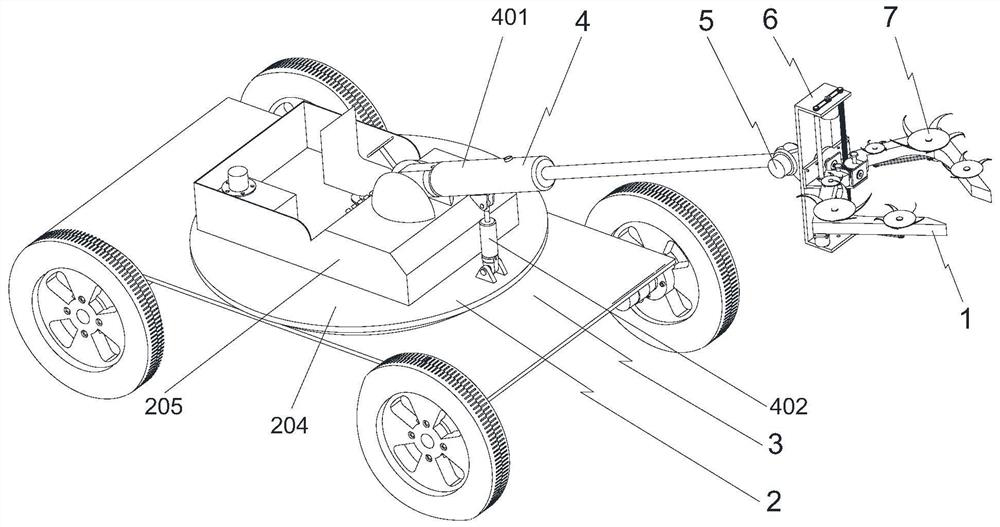

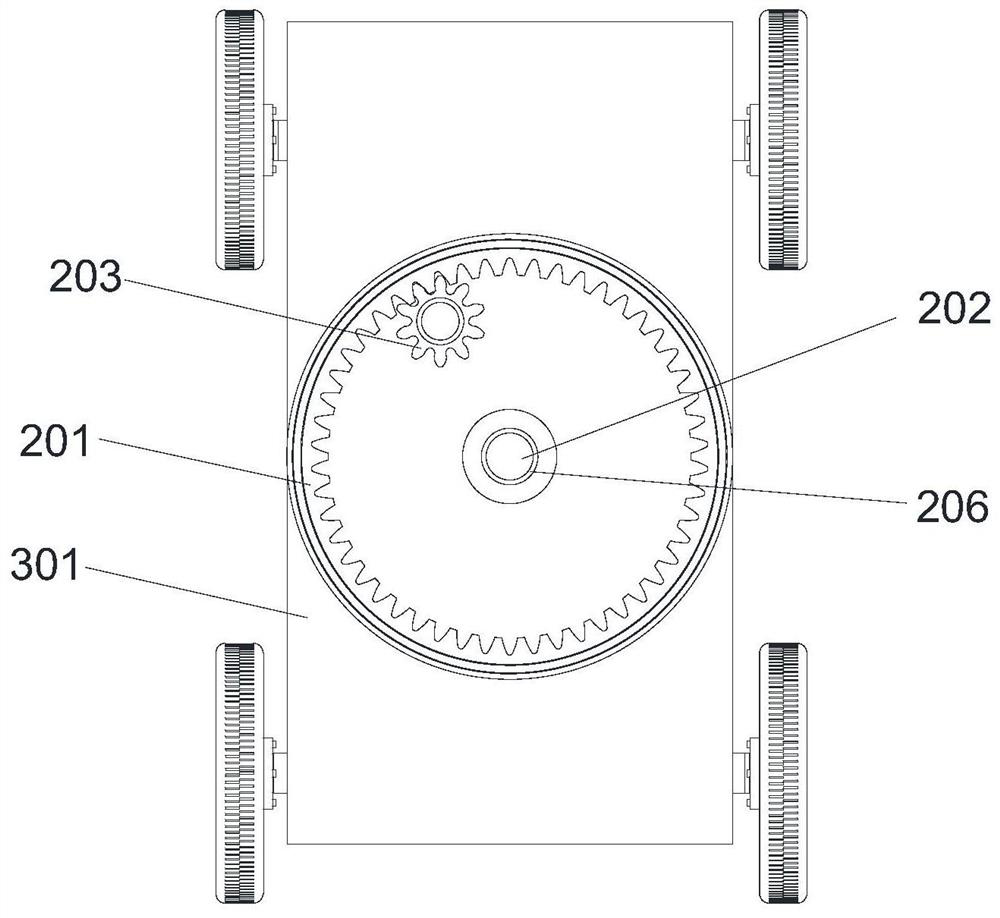

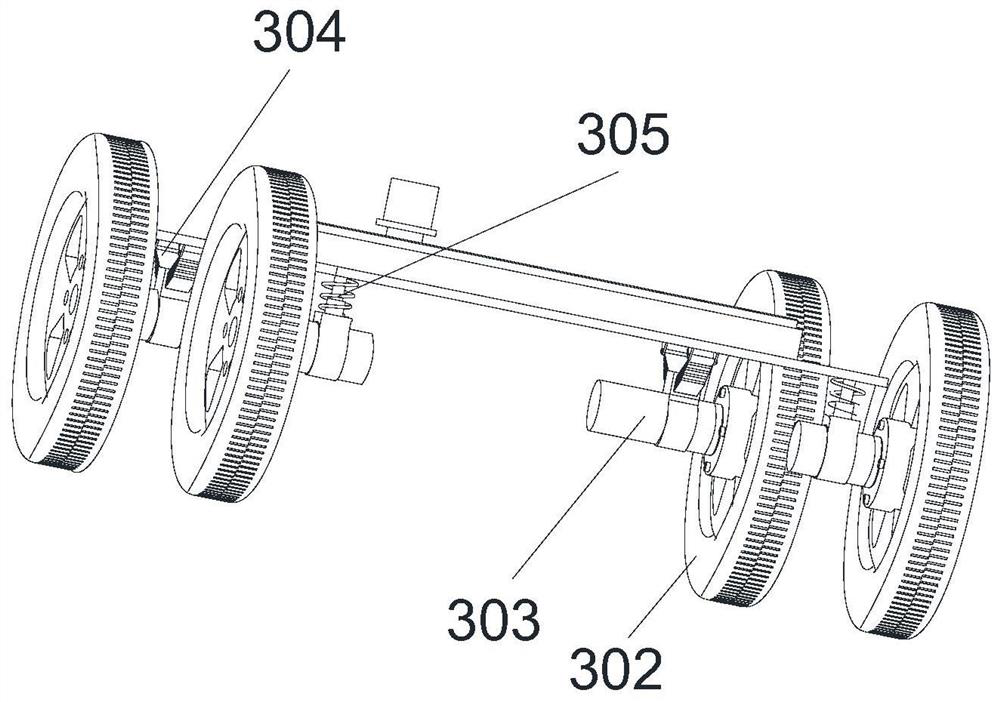

[0037] A two-way sisal harvester, comprising a cutting device for cutting sisal, a walking mechanism 3 that drives the cutting device to walk, a steering mechanism 2 that drives the cutting device to rotate around the Z axis, and a telescopic connection mechanism 4 that drives the cutting device to expand and contract. The Y-direction rotating mechanism 5 that drives the cutting device to rotate around the Y-axis, and the Z-direction feeding mechanism 6 that drives the cutting device to move up and down; the cutting device includes a manipulator mechanism 1 and a cutter mechanism 7. The disk device is close to the sisal from the side; the cutterhead mechanism includes a cutterhead 701, a blade 702 and a fourth motor 703, the fourth motor is connected with the cutterhead and drives the cutterhead to rotate, and the blade is fixed on the cutterhead and cuts with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com