Mud-water balance jacking pipe system and construction method thereof

A mud-water balance and construction method technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the problems of inconvenient sludge handling and transportation, soil wall slump damage, large water loss, etc. To achieve the effect of facilitating separation, treatment and transportation, avoiding water expansion, and balancing groundwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

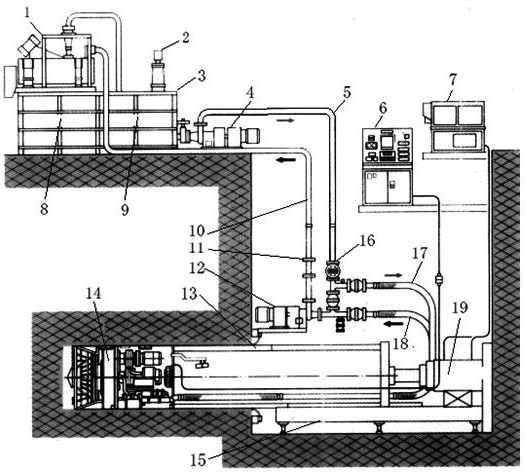

[0023] see figure 1 , Example: Guiyang Nanming District Guigang and other sewage treatment plants supporting pipe network water quality improvement project, located in Chaoyangdong Road to Yuchang Road, Nanming District, Guiyang City. The underground pipes and pipe jacking pipes are prefabricated reinforced concrete round pipes with an inner diameter of 2400mm, a wall thickness of 240mm, and a length of each section of 2.0m; the starting point of the project is located near the entrance of No. 29 Middle School in Guiyang City, Shachong Middle Road, and the end point of the project is located at Yuchang Road and Taoyuan At the road intersection, it is connected to the existing Nanming River sewage interception ditch, and the pipe jacking crossing area is a municipal road with a large traffic flow; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com