High earth-rock dam composite anti-seismic structure and construction method thereof

A technology for high earth-rockfill dams and earthquake-resistant structures, which is applied in basic structural engineering, excavation, dams, etc., can solve problems such as complex construction and poor durability, achieve good adaptability, improve seismic performance, and reduce lateral deformation and unevenness. subsidence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

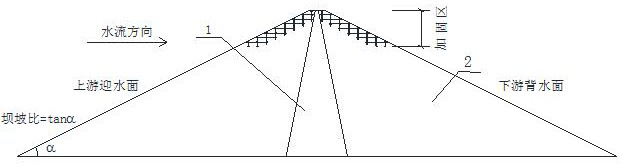

[0039] In this embodiment, a high earth-rock dam composite seismic structure and its construction method, refer to the attached Figure 1-2 , 4-5, the slope ratio of the upstream and downstream dams is 1:2.0, and when the filling reaches 1 / 4 of the dam height in the crest area, lay the first layer of steel mesh 3 horizontally in the upper and lower rockfills on both sides of the core wall 1, Rockfill 2 is filled from bottom to top on the reinforced mesh 3 to form a rockfill structure. The rockfill structure is arranged around the core wall 1 and has a trapezoidal longitudinal section. The reinforced mesh 3 is laid horizontally between the rockfill 2 every 5 meters. That is, the vertical spacing of the reinforcement mesh is 5m, the entire surface of the reinforcement mesh 3 is covered with neutral glass glue 7, and a plurality of high polymer rockfill composite piles 4 are arranged in the area from the central axis of the rockfill structure to the outer circumference of the rock...

Embodiment 2

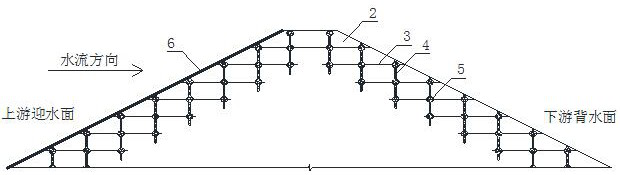

[0050] For the composite seismic structure of the high earth-rock dam in this embodiment, please refer to the attached Figure 3-5 As shown, the slope ratio of the upstream and downstream dams is 1:2.0. The difference between this embodiment and Embodiment 1 is that no core wall 1 is provided, and a panel 6 is provided on the facing surface of the high earth-rockfill dam.

[0051] When filling to 1 / 4 of the dam height in the dam crest area, lay the first layer of reinforcement mesh 3 horizontally in the upstream and downstream rockfills, and then lay a layer of reinforcement mesh 3 every 6m of filling;

[0052] One end of the steel mesh 3 is laid to the panel 6 and welded with the steel bars of the panel 6 as a whole, and the length of the other end laid along the river direction is not less than 27m. Upstream and downstream stone stacking;

[0053] Spray neutral glass glue 7 on the surface of steel mesh 3;

[0054] After the filling of the earth-rock dam is completed, verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com