Method for preparing xylan and high-purity lignin by taking gramineous plants as raw materials

A technology of gramineous plants and plant raw materials, applied in the field of dissolving pulp preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

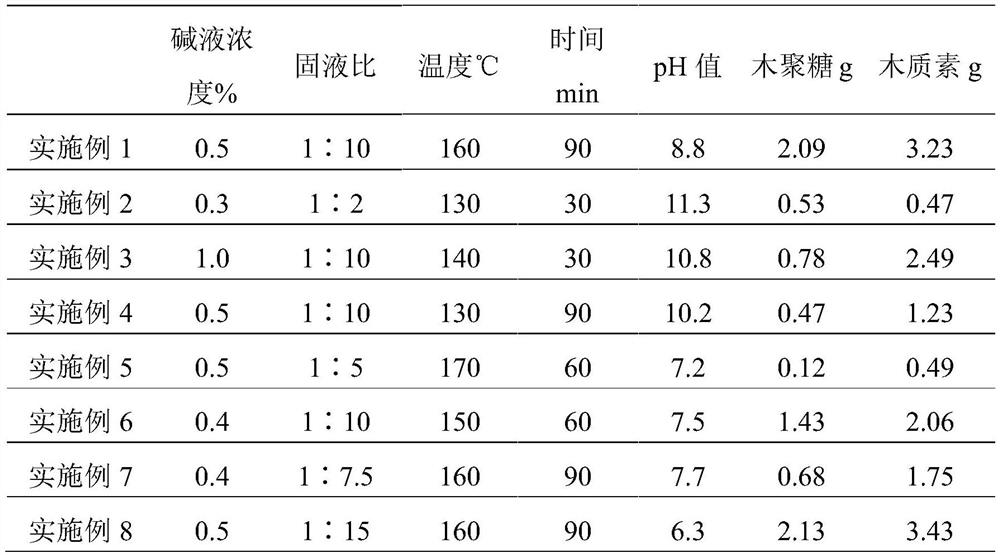

[0032]Example 1-8

Example Embodiment

[0033]Example 1 The preparation process is:

[0034]Preparation: The bamboo pieces are raw materials, dried into natural water content of 8% -12%, soaking in 0.5% NaOH aqueous solution;

[0035]Pred - hydrolysis: Add 1 part by weight of bamboo tablets to the reactor, add 10 parts of 0.5% NaOH aqueous solution, pretreatment of 90 minutes under 160 ° C, and cool to room temperature after the pre-treatment, and 60 mesh sieve separation prehydrolysis and material sheet;

[0036]Separation of lignin: The pH is adjusted to 2 in 4M hydrochloric acid, and the lignin is precipitated, centrifuged, and the sealed package is obtained, and the yield of refined lignin is 6.5%;

[0037]Isolation of xylosan: The supernatant after lignin was separated. The pH was adjusted to 7 with 4 M NaOH. After concentrating 10-30 times of ethanol, the xantan is precipitated, centrifuged, dry after drying Packaging, refined glycosaccharide is 4.2%; after evaporation of ethanol, recycling.

[0038]Example 2-8 Preparation Procedu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com