Electroplating equipment for two-side feeding and discharging of electroplated parts

A technology for electroplating equipment and electroplating parts, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of inability to rotate safety, hidden dangers and other problems of electroplating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

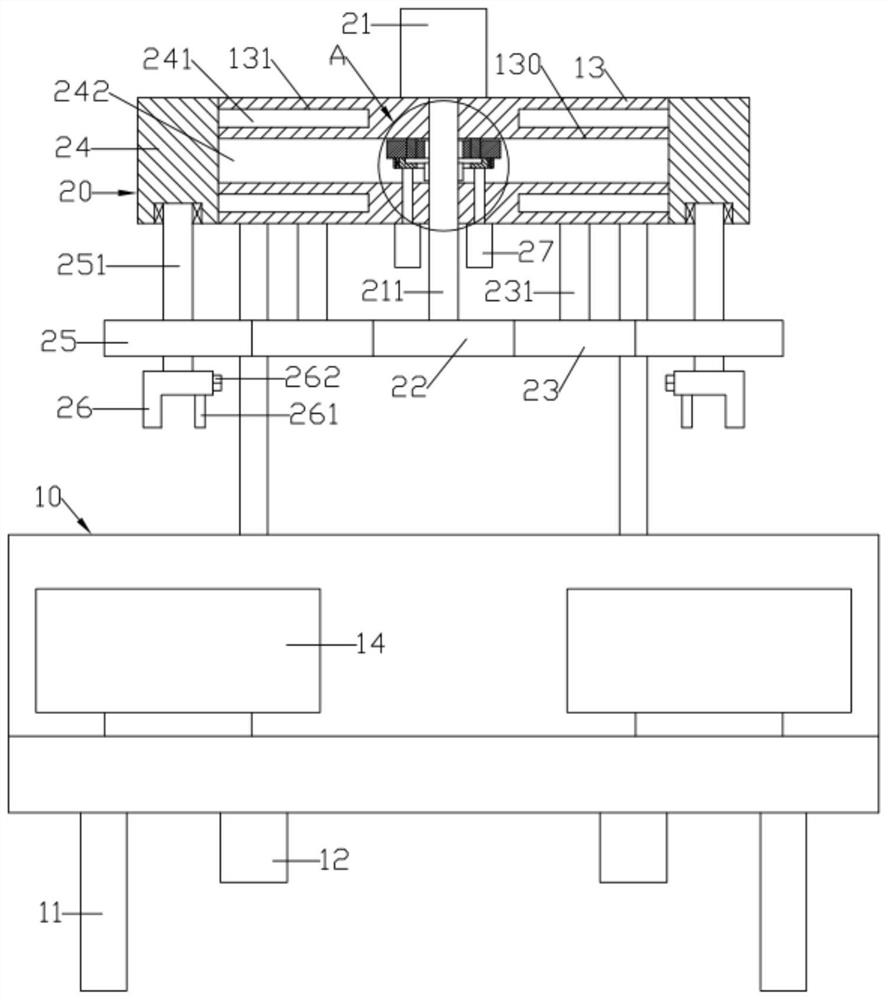

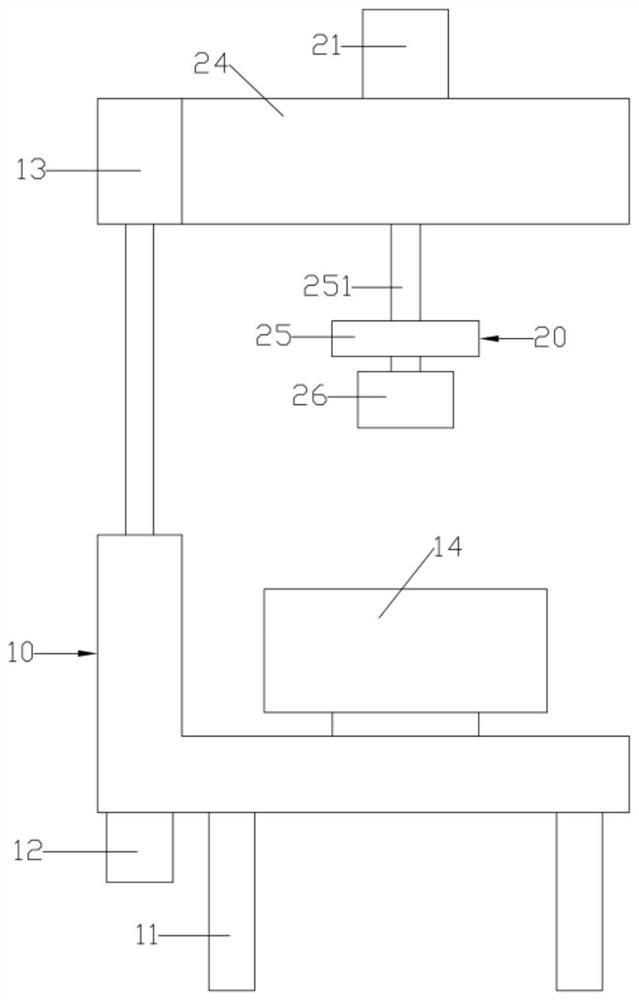

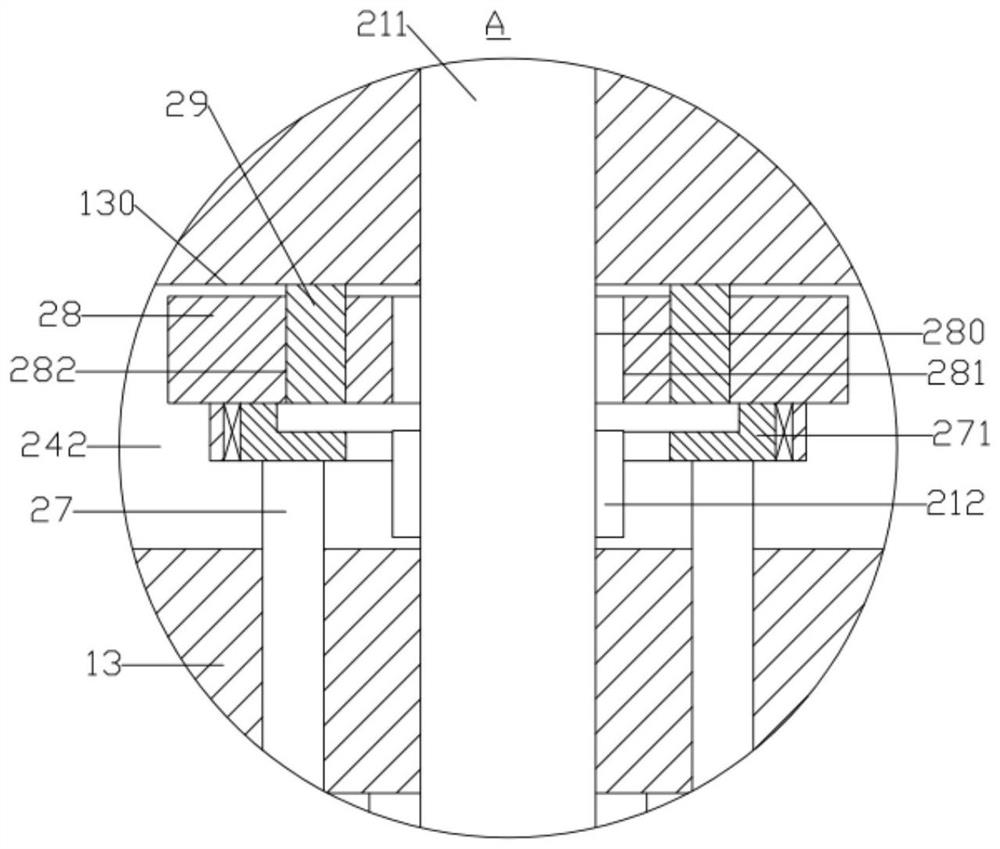

[0015] Such as Figure 1 ~ Figure 3 As shown, a kind of electroplating equipment for loading and unloading on both sides of an electroplating piece includes an L-shaped support frame 10 and a driving device 20; the bottom of the support frame 10 is provided with several support feet 11; The electroplating tank 14 arranged symmetrically on the left and right; the center lifting plate 13 is arranged up and down directly above the support frame 10; the left and right moving grooves 130 are formed on the center lifting plate 13; the driving device 20 includes a pair of left and right moving seats 24; A pair of left and right moving seats 24 are arranged on the left and right sides of the center lifting plate 13 for left and right movement respectively; the end faces of a pair of left and right moving seats 24 that are close to each other are formed with left and right driving racks 242 respectively; In the slot 130; a pair of left and right driving racks 242 are distributed front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com