Surface non-polar modification method of sepiolite mineral powder and application of sepiolite mineral powder in plastic or rubber filler

A technology for mineral powder and sepiolite, which is applied in the field of rubber and plastic fillers, can solve the problems of high cost, affecting the production, use and promotion of modified sepiolite mineral powder, and harsh conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The present invention prepares surface non-polarized sepiolite mineral powder, and its preferred embodiment is:

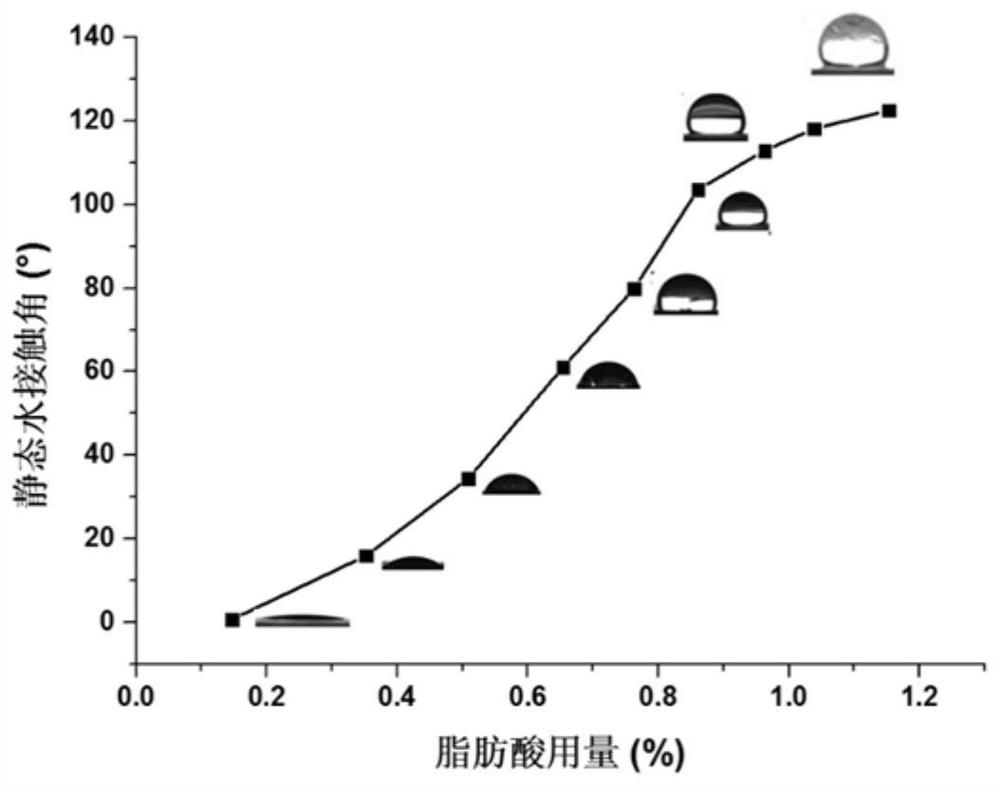

[0026] The formula components and their weight ratios are (based on the weight of sepiolite mineral powder), sepiolite mineral powder: palmitic acid: absolute ethanol: ferric chloride hexahydrate: water=1:0.0008~0.02: 3.945: 0.006850~0.027375: 7.5; the reaction conditions are: reaction time 10~100min, modification temperature 30~60℃.

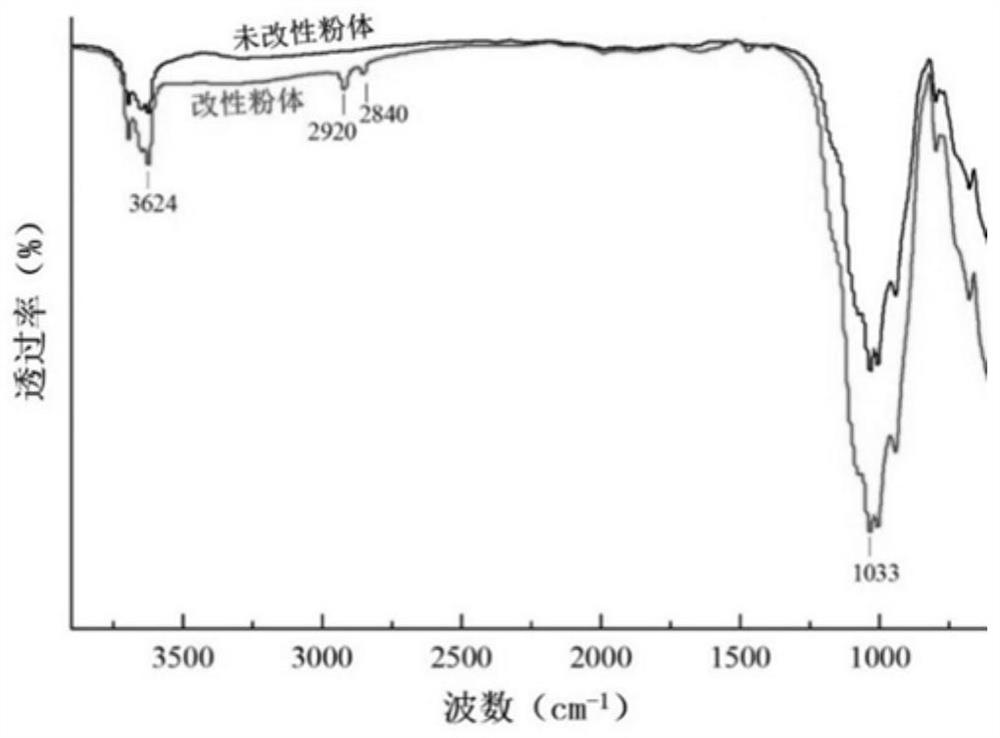

[0027] The palmitic acid, namely "hexadecanoic acid", has more carbon atoms in the molecular chain and is highly non-polar, so it can be non-polarized by grafting on the surface of the sepiolite mineral powder. The absolute ethanol is a solvent for palmitic acid, which plays a role in promoting the dispersion of palmitic acid molecules in the reaction system. Described ferric chloride hexahydrate is catalyzer, and ferric chloride is a kind of strong Lewis acid, and catalytic mechanism is that the outer layer empty track of Le...

Embodiment 1

[0029] Embodiment 1: the mass ratio of each component of the present embodiment and concrete steps are:

[0030] Sepiolite mineral powder: palmitic acid: absolute ethanol: ferric chloride hexahydrate: water=1:0.02:3.945:0.027375:7.5.

[0031] 1) Weigh 0.08g of palmitic acid into a 50mL beaker, then add 20mL of absolute ethanol, and stir until completely dissolved;

[0032] 2) Weigh 4g of sepiolite mineral powder and add it to a 100mL beaker, then add 30mL of deionized water, stir evenly with a heat-collecting magnetic stirrer at a speed of 300r / min, and the temperature of the water bath is 30°C;

[0033] 3) Weigh 0.1095g FeCl 3 ·6H 2 O joins in the beaker in step 2), stirs until dissolving completely;

[0034] 4) Add the palmitic acid ethanol solution prepared in step 1) into the beaker in step 3), keep the rotation speed and the temperature of the water bath constant, and react for 40 minutes;

[0035] 5) Suction filter the reaction solution in step 4), wash twice with 30...

Embodiment 2

[0036] Embodiment 2: the mass ratio of each component of the present embodiment and concrete steps are:

[0037] Sepiolite mineral powder: palmitic acid: absolute ethanol: ferric chloride hexahydrate: water = 1: 0.015: 3.945:: 0.027375: 7.5.

[0038] 1) Weigh 0.06g of palmitic acid into a 50mL beaker, then add 20mL of absolute ethanol, and stir until completely dissolved;

[0039] 2) Weigh 4g of sepiolite mineral powder and add it to a 100mL beaker, then add 30mL of deionized water, stir evenly with a heat-collecting magnetic stirrer at a speed of 300r / min, and the temperature of the water bath is 30°C;

[0040] 3) Weigh 0.1095g FeCl 3 ·6H 2 O joins in the beaker in step 2), stirs until dissolving completely;

[0041] 4) Add the palmitic acid ethanol solution prepared in step 1) into the beaker in step 3), keep the rotation speed and the temperature of the water bath constant, and react for 40 minutes;

[0042] 5) Suction filter the reaction solution in step 4), wash twice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com