Ammonia water synthesis process

A synthesis process, ammonia water technology, applied in the preparation/separation of ammonia, etc., can solve the problems of complex operation and high investment cost, and achieve the effect of simple process operation and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

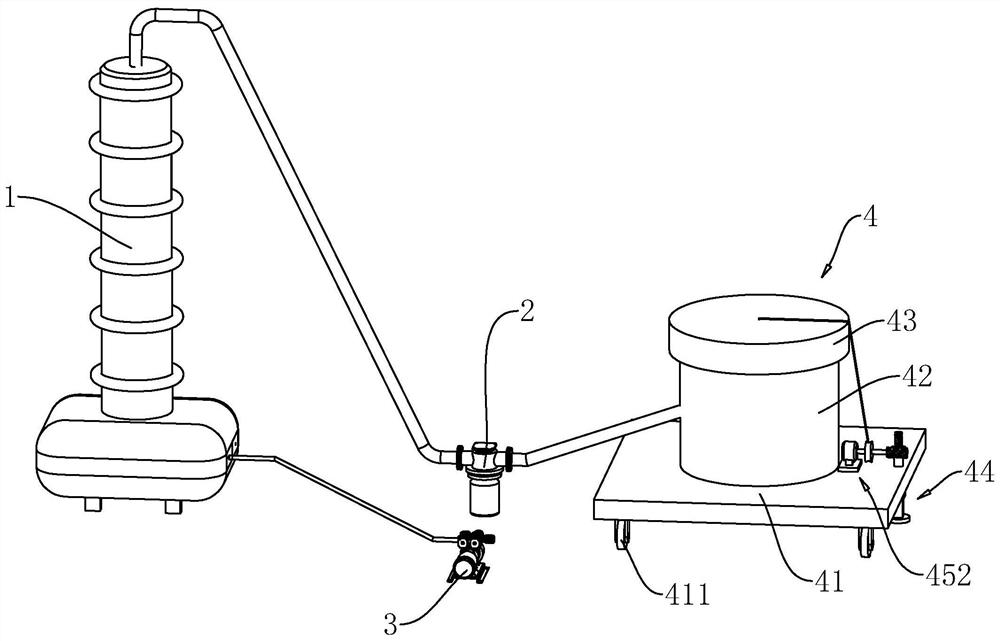

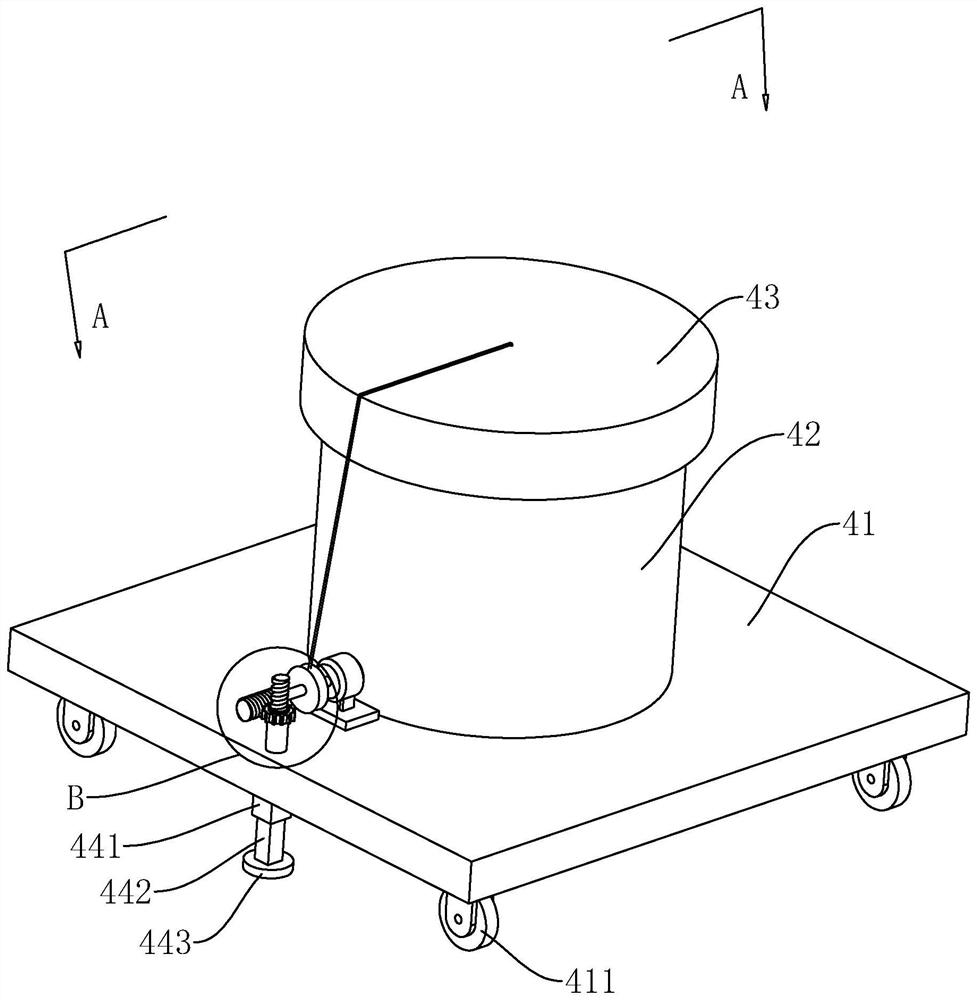

[0033] The following is attached Figure 1-4 The application is described in further detail.

[0034] The embodiment of the present application discloses an ammonia water synthesis process. refer to figure 1 , including the following steps:

[0035] S1: Pass the tail gas containing ammonia gas into the lower end of the ammonia absorption tower 1, the desalinated water station will store the processed desalted water in the desalted water storage tank 4, start the delivery pump 2, and the delivery pump 2 will transfer the desalted water to the desalted water storage tank 4 The desalted water is passed into the ammonia absorption tower 1 to absorb the ammonia gas, the desalted water enters the ammonia absorption tower 1 and then falls, and finally enters the lower end of the ammonia absorption tower 1, and the water intake of the desalinated water is controlled by liquid level interlocking;

[0036] S2: The desalted water in the gas ammonia absorption tower 1 is cooled by a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com