A kind of preparation method of particle size controllable calcium silicate and calcium silicate prepared by the same and use

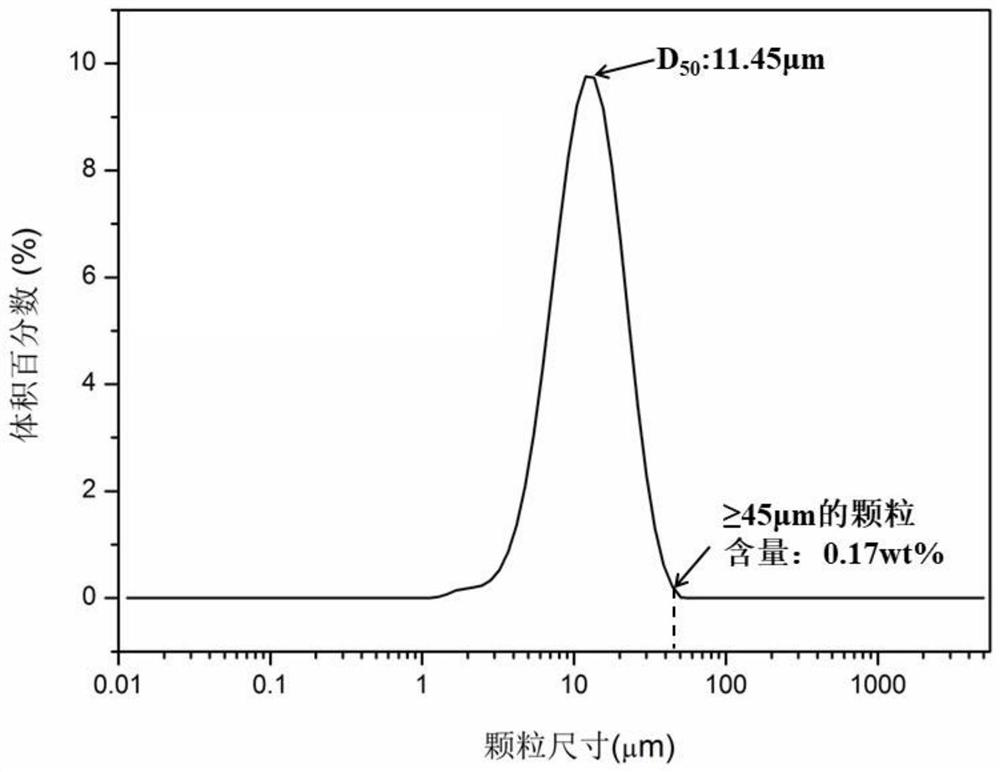

A calcium silicate and particle size technology, applied in the field of calcium silicate, can solve the problems of difficulty in meeting particle size requirements, wide range of calcium silicate particle size, increased energy consumption in the preparation process, etc., to reduce the use of wood, The effect of mild reaction conditions and easy industrialization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

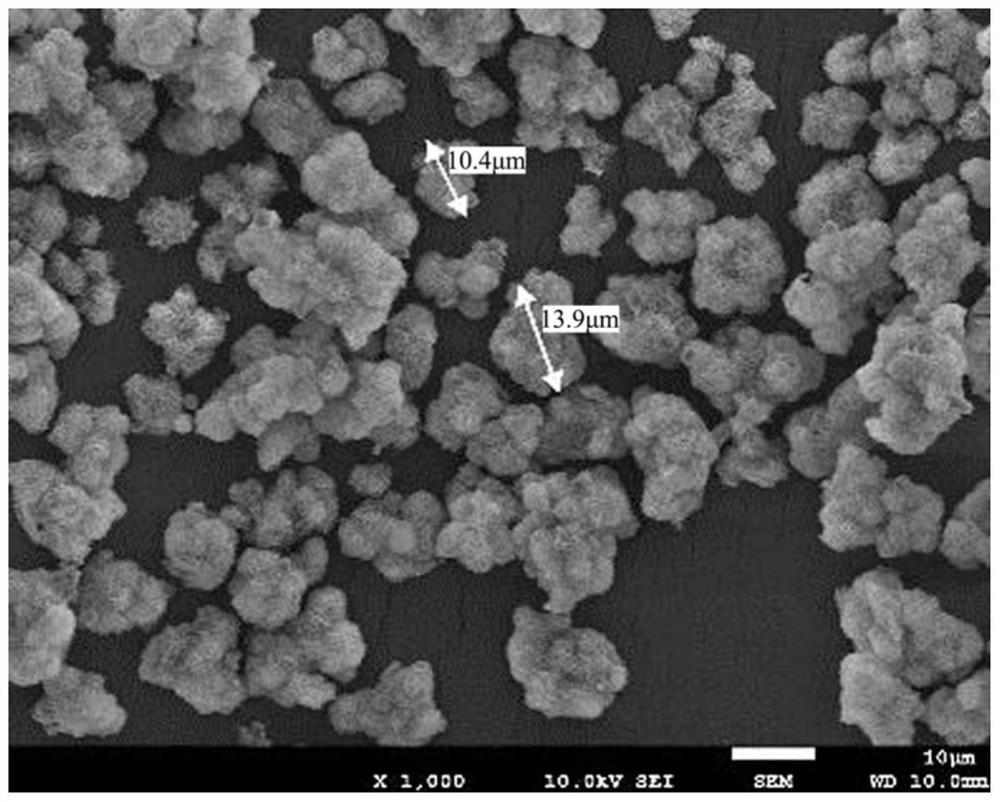

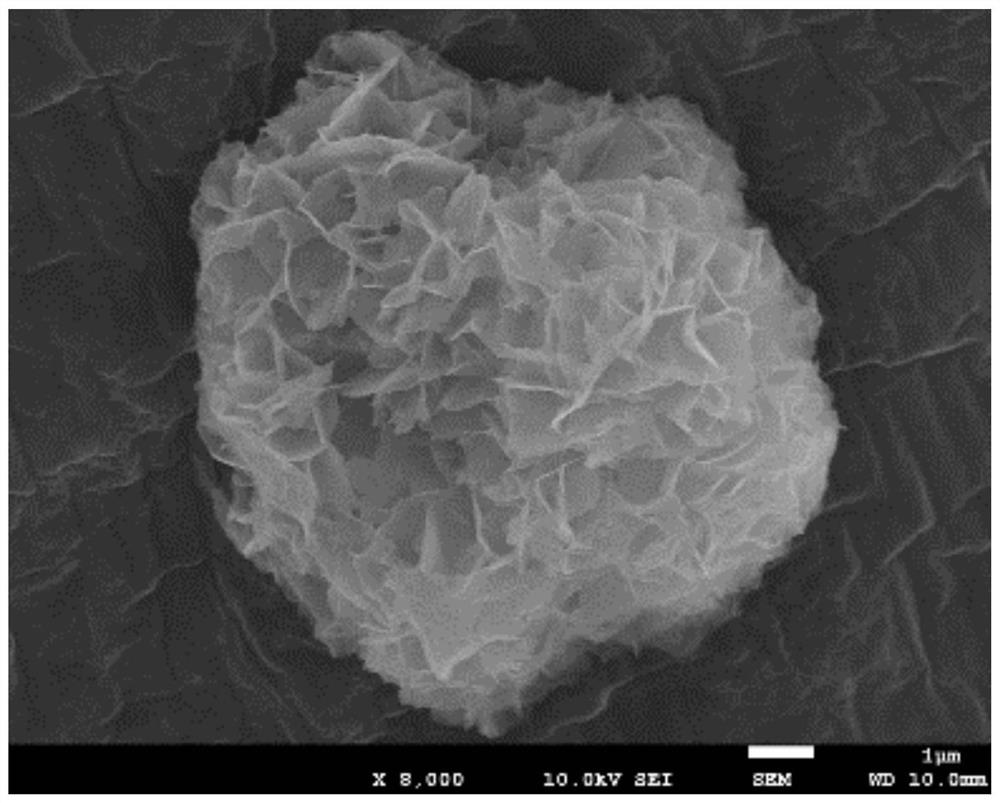

Method used

Image

Examples

Embodiment 1

[0070] The present embodiment provides a preparation method of calcium silicate, and the method comprises the following steps:

[0071] (1) make 0.1L silicate-containing sodium hydroxide solution as auxiliary solution and mix well with lime under the stirring condition of 400r / min, obtain mixed solution, wherein, the alkali concentration in the described silicate-containing sodium hydroxide solution with Na 2 O is 96g / L, and the silicate concentration is SiO 2 Calculated as 0.53g / L;

[0072] (2) heating the mixed solution to 96°C;

[0073] (3) At 96 °C, the concentration of 0.2 L of alkali was changed to Na in 1 h. 2 O is 96g / L, and the silicate concentration is SiO 2 The sodium silicate solution calculated as 36g / L is dropped into the mixed solution at a uniform speed to obtain a reaction solution; wherein, the sodium silicate solution is obtained from low-grade bauxite (A / S ratio ~ 2) under the action of alkali solution. The sodium silicate solution that silicon pretreatm...

Embodiment 2

[0078] The present embodiment provides a preparation method of calcium silicate, and the method comprises the following steps:

[0079] (1) make 0.3L silicate-containing sodium hydroxide solution as auxiliary solution and mix well with calcium hydroxide reagent under the stirring condition of 300r / min to obtain mixed solution, wherein, auxiliary solution is prepared by commercially available sodium silicate reagent Silicate-containing sodium hydroxide solution, the alkali concentration in the silicate-containing sodium hydroxide solution is Na 2 O is 80g / L, silicate concentration is SiO 2 Calculated as 4.8g / L;

[0080] (2) heating the mixed solution to 90°C;

[0081] (3) At 90 °C, the concentration of 1 L of alkali was changed to Na in 2 h. 2 O is calculated as 37.2g / L, and the silicate concentration is calculated as SiO 2 The sodium silicate solution calculated as 36g / L is dropped into the mixed solution at a uniform speed to obtain a reaction solution; wherein, the sodiu...

Embodiment 3

[0084] The present embodiment provides a preparation method of calcium silicate, and the method comprises the following steps:

[0085] (1) make 0.1L silicate-containing sodium hydroxide solution as auxiliary solution and mix well with lime under the stirring condition of 400r / min, obtain mixed solution, wherein, the alkali concentration in the described silicate-containing sodium hydroxide solution with Na 2 O is 220g / L, silicate concentration is SiO 2 Calculated as 0.6g / L;

[0086] (2) heating the mixed solution to 80°C;

[0087] (3) At 80°C, the concentration of 0.2L alkali was changed to Na in 1 h. 2 O is 25g / L, silicate concentration is SiO 2 The sodium silicate solution calculated as 78g / L is dropped into the mixed solution at a uniform speed to obtain a reaction solution; wherein, the sodium silicate solution is the sodium silicate solution prepared by commercially available water glass, and the calcium in the step (1) lime With the silicon in the sodium silicate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com