Installing and positioning method for parts on outer surfaces of blades of wind turbine generator

A technology for installation and positioning of wind turbines, which is applied to wind power generation, wind engines, engines, etc., can solve the problems of location accuracy and poor quality that consume a long time, save operating hours, determine the location accurately and reliably, and facilitate search Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

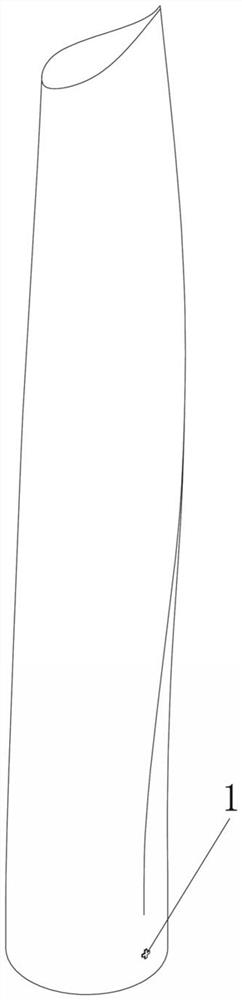

[0030] This embodiment provides a method for installing and positioning components on the outer surface of a blade of a wind turbine, comprising the following steps:

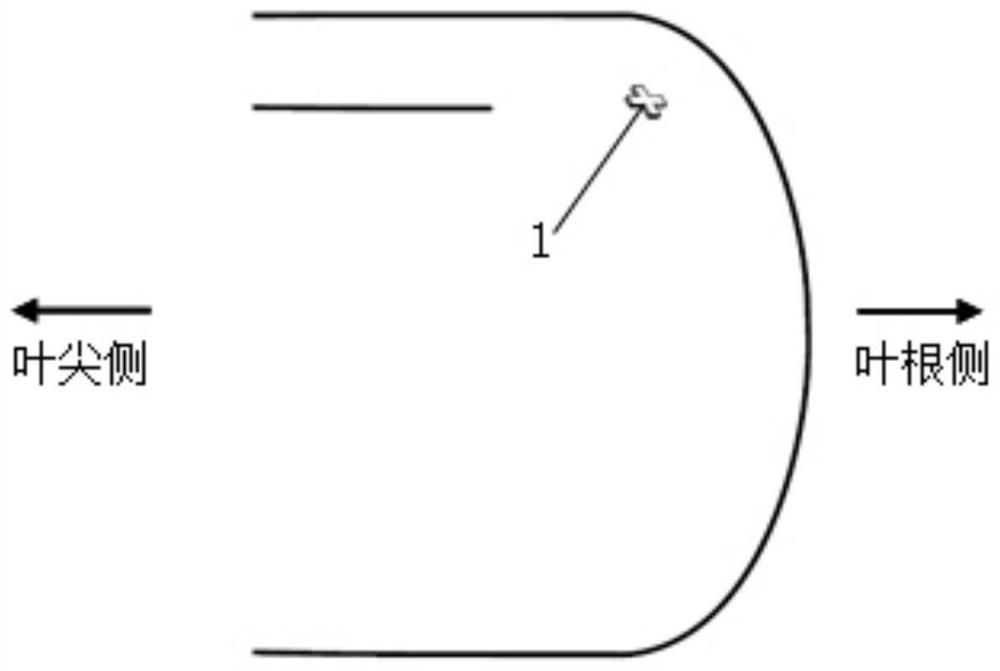

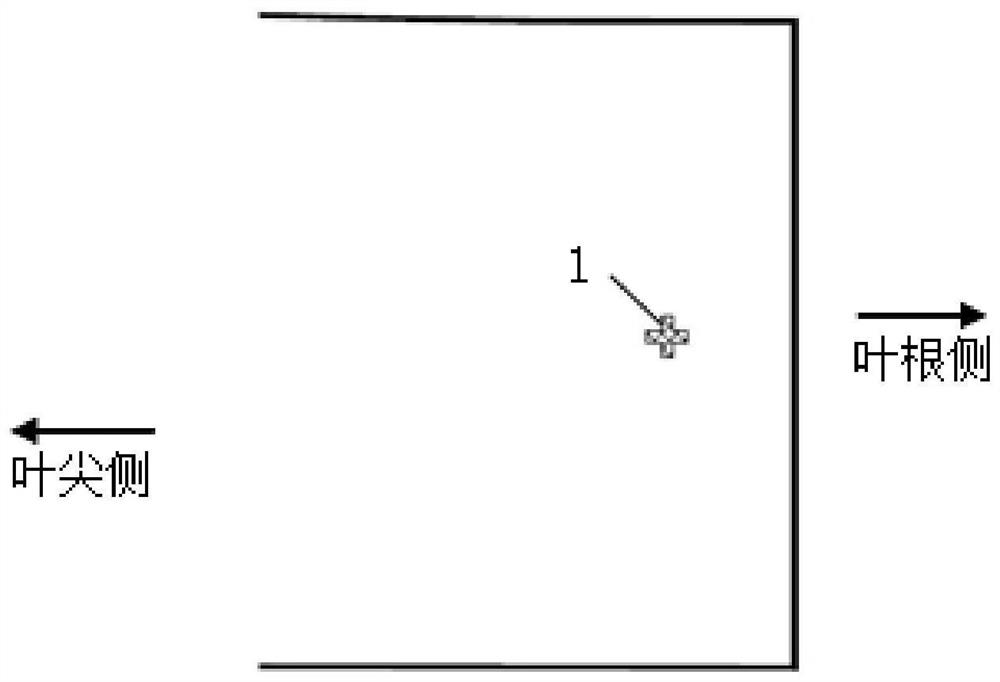

[0031] 1) Positioning in the mold

[0032] First, according to the chord and axial data of the component installation position (such as lightning receptors, vortex generators, noise reduction sawtooth blades, etc.) or operating positions (such as counterweight position, weighing position, etc.) Accurately measure the corresponding data on the inner surface of the mold and draw marks; the female mold is the basis for making blades, and its accuracy directly determines the accuracy of the blade shape. It is easy to find, it is a very direct, relatively accurate and easy-to-operate way to mark on the inner surface of the female mold through its meter mark and the leading and trailing edges, and then transfer to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com