Low-noise stamping die and method

A stamping die and low-noise technology, applied in the field of stamping noise reduction, can solve the problems of high sound pollution in the working environment, high stamping noise, and serious physical injury to operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

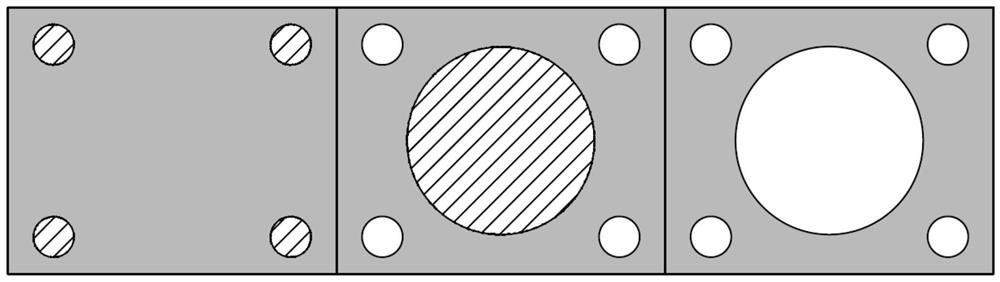

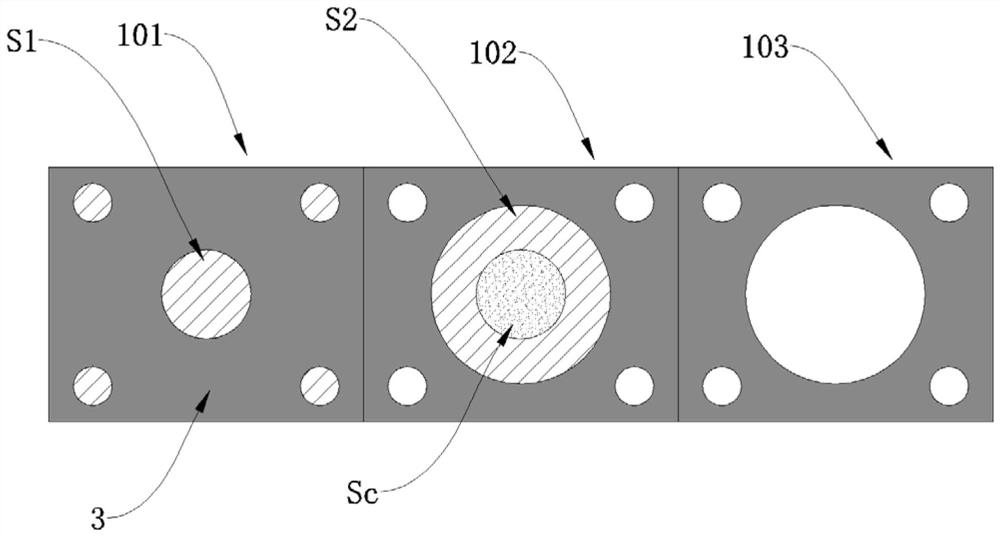

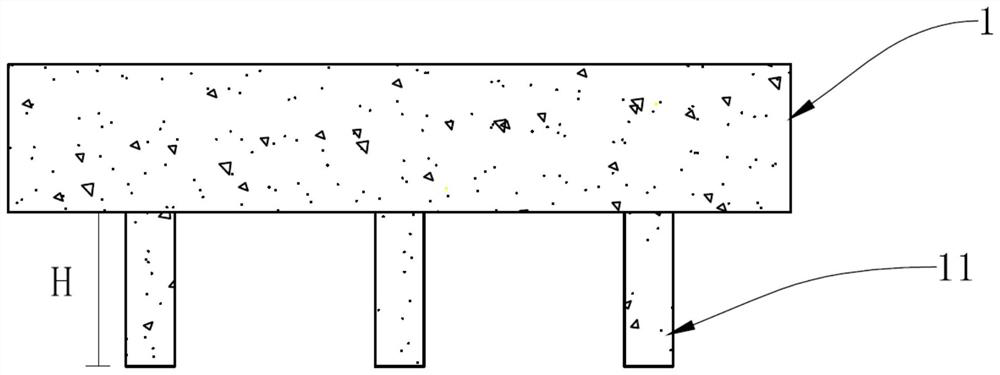

[0028] refer to figure 2 and Figure 4 , the present embodiment provides a low-noise stamping die, including an upper mold base 1 and a lower mold base, and the upper mold base 1 and the lower mold base are sequentially provided with several stations along the conveying direction of the product blank 3, including the first The first station 101, the second station 102, the third station 103, etc., the upper mold base 1 is divided into a plurality of progressive dies in turn, and each progressive die is provided with at least one punch 11 on the parting die. There is a progressive die corresponding to the position, and the lower die base is used to support the product blank 3 and transmit the product blank 3. In one mold clamping, several punches 11 respectively punch the product blank 3 and transfer the product blank 3 Corresponding holes with a certain area are formed on the blank 3, and the projected areas of the punches 11 on the same progressive die parting on the transm...

Embodiment 2

[0038] refer to figure 2 , this embodiment 2 provides a method applied to the above-mentioned low-noise stamping die. The first-stage punch 11 punches out a hole with a projected area of S1 on the product blank 3. On this basis, the second-stage punch 11 The blank 3 of the product is punched out of a hole with a projected area of S2, wherein when the projected area corresponding to the second-stage punch 11 overlaps with the projected area corresponding to the first-stage punch 11, the area of the overlapping area is defined as is Sc, the projected area corresponding to the second-stage punch 11 is S2-Sc; and so on, the projected area S corresponding to each punch 11 is between 90% and 110% Sp, where Sp is the average value of the projected area .

[0039] In addition, if the punch 11 of the previous stage punches out a plurality of relatively scattered holes on the product blank 3, but the punch 11 of the latter stage only overlaps with one or more of the holes, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com