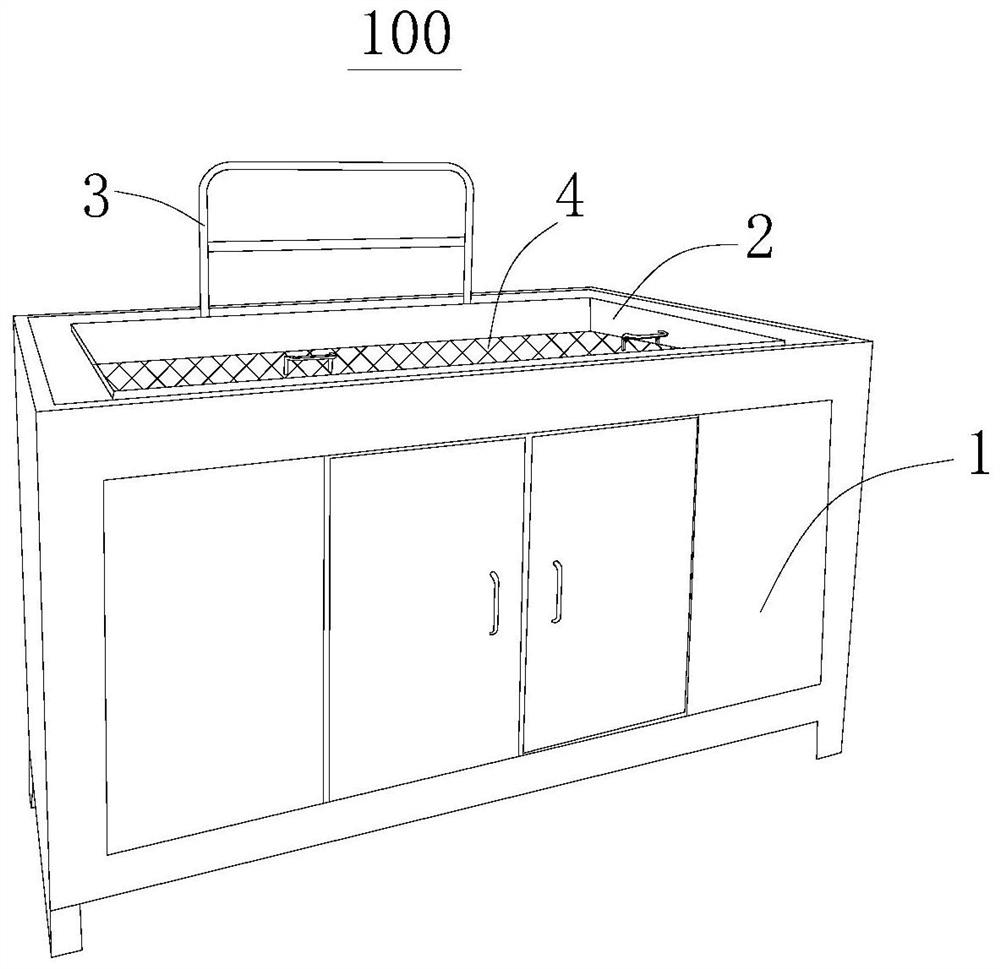

Small alkaline washing tank of hot rails in elasticizer and alkaline washing process

A technology of alkali washing tank and texturing machine, which is applied in the field of polyester processing, can solve the problems of increased polyester filament dyeing stripes, affecting the quality rate, and production costs, so as to improve the quality rate, reduce production costs, and improve surface quality. The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

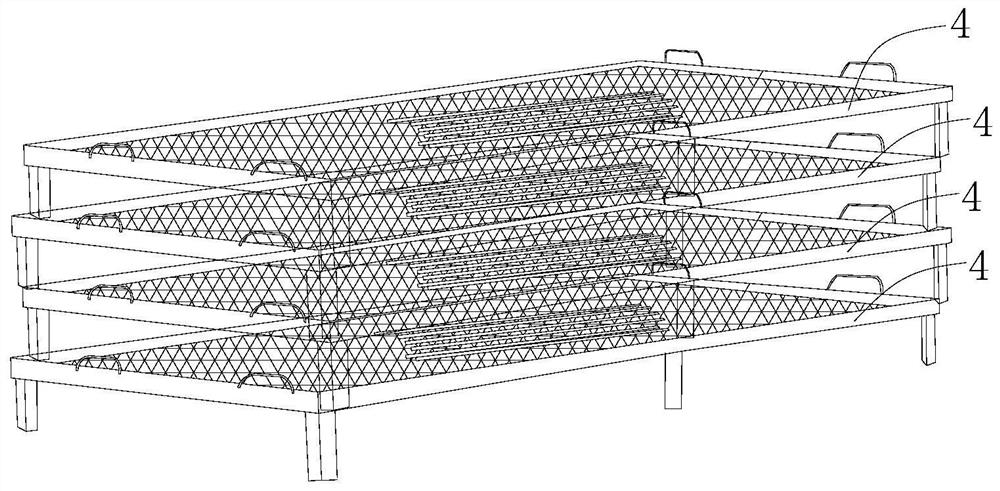

[0047] Specific embodiments of the application are described in conjunction with the drawings and the following description to teach those skilled in the art how to make and use the best mode of the application. Conventional aspects have been simplified or omitted in order to teach application principles. Those skilled in the art will appreciate that variations from these examples fall within the scope of the application. Those skilled in the art will appreciate that the features described below can be combined in various ways to form multiple variations of the application. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this application are only for the convenience of description and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com