Petrochemical liquid storage tank air bag type floating block sampling device

A sampling device, air bag type technology, applied in the field of petrochemical liquid storage tank air bag type floating block sampling device, to achieve the effect of simple structure, wide application range and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

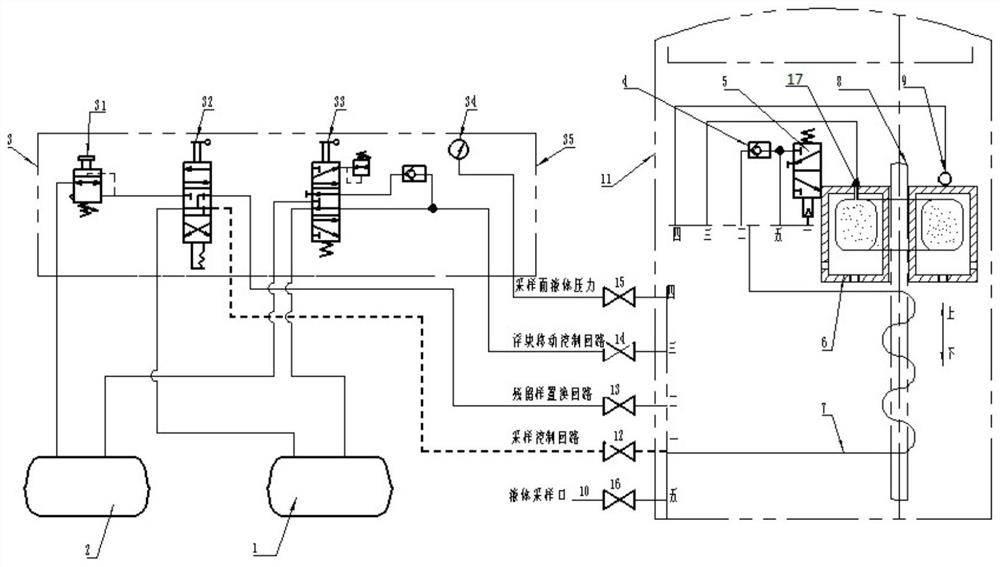

[0032] Attached below figure 1 And embodiment the present invention is further described.

[0033] Refer to attached figure 1 As shown, the present invention is a petrochemical liquid storage tank airbag float sampling device, including a vacuum tank 1, a nitrogen pressure tank 2, an air control box 3, a one-way valve 4, a sampling valve 5, an airbag float 6, and a tube bundle 7. Floating disk anti-rotation rope 8, wherein the air control box 3 includes a pressure reducing valve 31, a sampling replacement control valve 32, a float control valve 33, a liquid level pressure gauge 34, an air control box 35, and an air bag type float 6. On the floating disk anti-rotation rope 8, the vacuum tank 1, the sampling replacement control valve 32, and the sampling valve 5 are connected to form a sampling control circuit (one and one of the two joints in the figure are connected to the first tube by gas passage), and the vacuum tank 1 , the floating block control valve 33, the air bag po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com