Specially-made low-heat-generation rubber and preparation method thereof

A low heat generation and rubber technology, applied in the field of rubber, can solve the problems of low heat generation, tire strength, insufficient heat generation, etc., and achieve the effects of improved service life, permanent deformation, good tensile strength and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

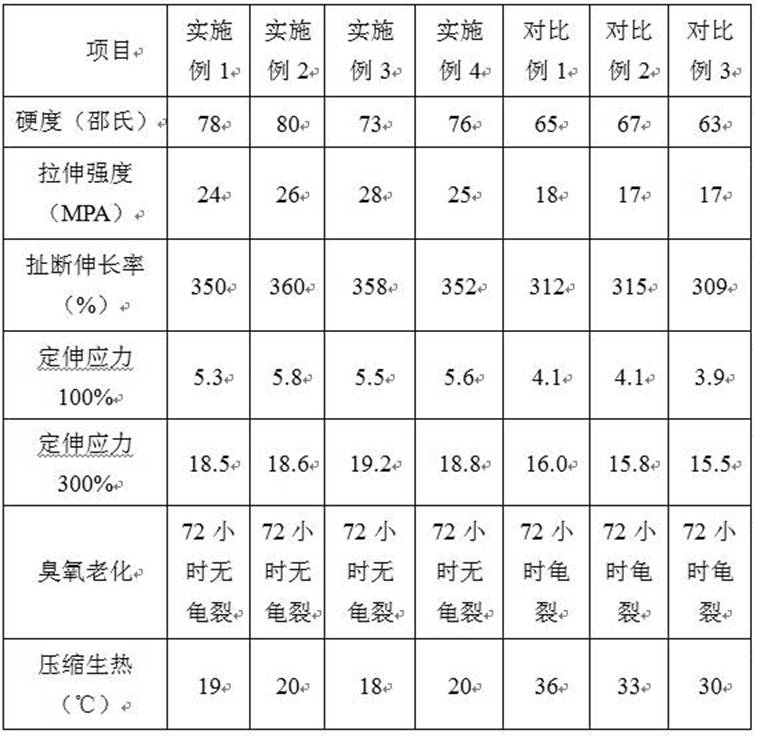

Examples

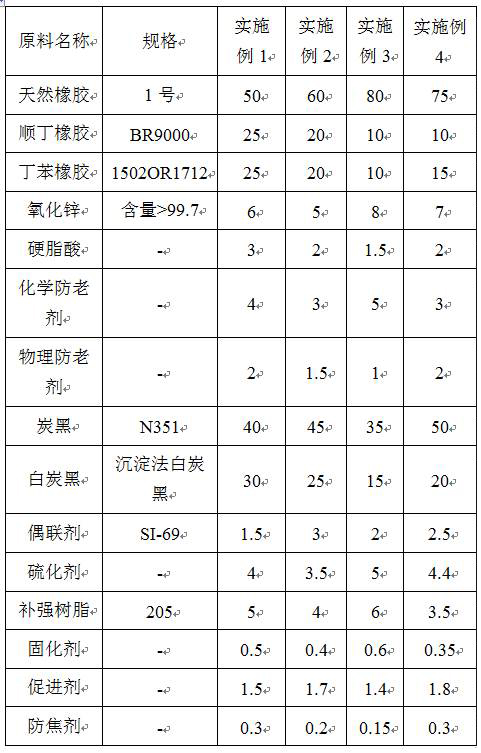

Embodiment 1

[0028] The components of the rubber are shown in Table 1. The accelerator includes tetramethylthiuram disulfide, di-o-tolylguanidine, and phenformin with a weight ratio of 1:0.5:0.5; the chemical antioxidant is 4010Na with a mass ratio of 1:2. , 4020; the physical anti-aging agent is polyethylene wax and microcrystalline wax with a mass ratio of 2:1; the anti-scorch agent is PVI; the curing agent is HMT.

[0029] The preparation method of the above-mentioned special low heat generation rubber comprises the following steps:

[0030] A. Prepare materials according to Table 1;

[0031] B. Plasticizing natural rubber, butadiene rubber BR9000 and styrene-butadiene rubber in an internal mixer to make a plasticizing film;

[0032] C, adding carbon black, white carbon black, zinc oxide, stearic acid, chemical anti-aging agent, physical anti-aging agent, coupling agent, reinforcing resin, curing agent, anti-scorch agent to the plasticized film obtained in step B, Mix in the mixer for...

Embodiment 2

[0035] The components of the rubber are shown in Table 1. The accelerator includes tetramethylthiuram disulfide, di-o-tolylguanidine, and phenformin with a weight ratio of 1:1.3:1; the chemical antioxidant is BLE with a weight ratio of 2:1. , RD; the physical anti-aging agent is microcrystalline wax and paraffin wax with a mass ratio of 1:1; the anti-scorch agent is CTP; the curing agent is HMMM;

Embodiment 3

[0037] The components of the rubber are shown in Table 1. The accelerator includes tetramethylthiuram disulfide, di-o-tolylguanidine, and phenformin with a weight ratio of 1:0.8:0.5; the chemical anti-aging agent is BLE; the physical anti-aging agent is microcrystalline Wax; the anti-scorch agent is CTP; the curing agent is HMT; the preparation method of the special low heat generation rubber is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com