Visible-light-responsive photocatalytic antibacterial healing-promoting hydrogel and preparation method thereof

A healing hydrogel and photocatalytic technology, applied in medical science, bandages, etc., can solve the problems of tissue damage, no reduction in infection, etc., achieve the effect of simple method, reduce bacterial infection, and promote wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

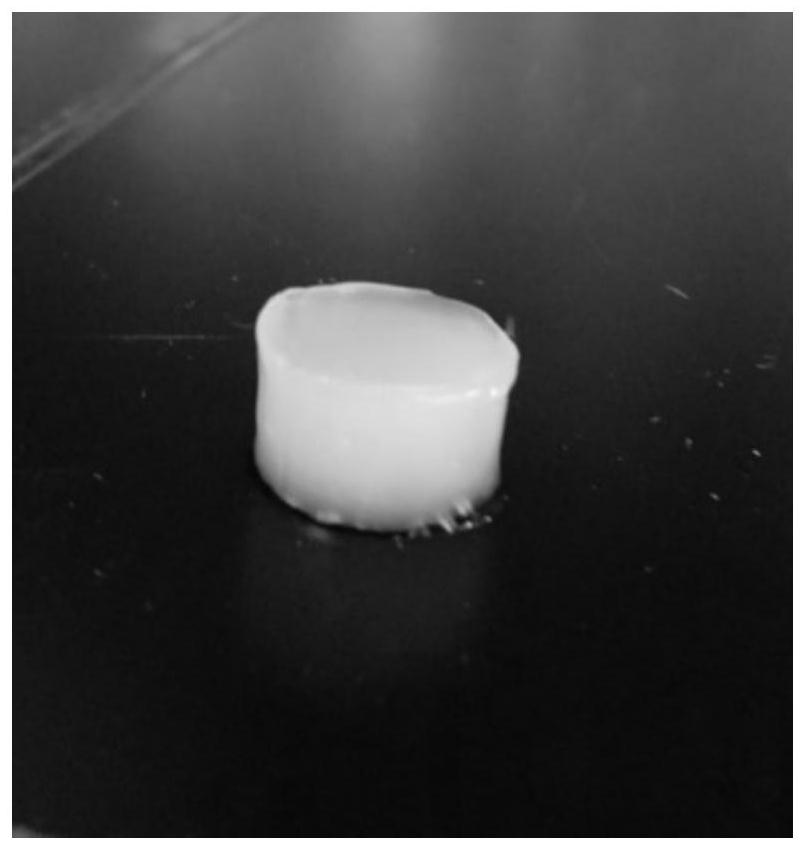

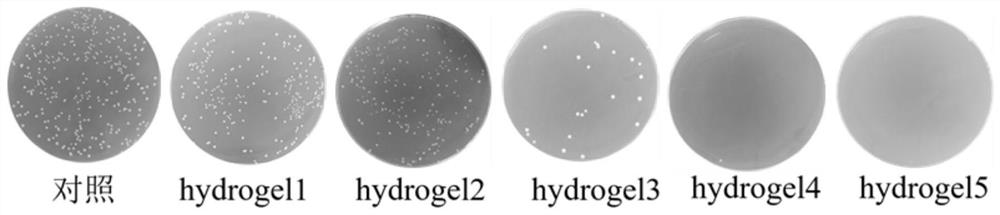

[0035] Weigh 20 mg of collagen and dissolve it in 2 mL of 1% acetic acid solution, stir well to dissolve it, and then adjust the pH to neutral with 1M sodium hydroxide solution to obtain a collagen solution. Weigh 40 mg of sodium alginate and dissolve it in 2 mL of deionized water, stir well to dissolve it, and obtain a sodium alginate solution. Add the sodium alginate solution into the collagen solution under stirring condition, and stir thoroughly to obtain the collagen-sodium alginate solution. Disperse graphite-phase carbon nitride nanosheets in deionized water, and ultrasonically treat for 30 minutes to obtain a uniform 0.6mg / mL graphite-phase carbon nitride nanosheet dispersion. Mix 1mL carbon nitride nanosheet dispersion with collagen-sodium alginate Mix the solution (the amount of graphite phase carbon nitride nanosheets is 1% of the total mass of collagen and sodium alginate), stir at room temperature for 2 hours, centrifuge to remove air bubbles, pour into a mold, le...

Embodiment 2

[0037] Weigh 20 mg of collagen and dissolve it in 2 mL of 1% acetic acid solution, stir well to dissolve it, and then adjust the pH to neutral with 1M sodium hydroxide solution to obtain a collagen solution. Weigh 40 mg of sodium alginate and dissolve it in 2 mL of deionized water, stir well to dissolve it, and obtain a sodium alginate solution. Add the sodium alginate solution into the collagen solution under stirring condition, and stir thoroughly to obtain the collagen-sodium alginate solution. Disperse graphite-phase carbon nitride nanosheets in deionized water and ultrasonically treat them for 30 minutes to obtain a uniform 1.2mg / mL graphite-phase carbon nitride nanosheet dispersion. Mix 1mL carbon nitride nanosheet dispersion with collagen-sodium alginate The solution was mixed (the amount of graphite phase carbon nitride nanosheets was 2% of the total mass of collagen and sodium alginate), stirred at room temperature for 2 hours, centrifuged to remove air bubbles, poure...

Embodiment 3

[0039] Weigh 20 mg of collagen and dissolve it in 2 mL of 1% acetic acid solution, stir well to dissolve it, and then adjust the pH to neutral with 1M sodium hydroxide solution to obtain a collagen solution. Weigh 40 mg of sodium alginate and dissolve it in 2 mL of deionized water, stir well to dissolve it, and obtain a sodium alginate solution. Add the sodium alginate solution into the collagen solution under the condition of stirring, and stir thoroughly to obtain the collagen-sodium alginate solution. Disperse graphite-phase carbon nitride nanosheets in deionized water and ultrasonically treat them for 30 minutes to obtain a uniform 1.8mg / mL graphite-phase carbon nitride nanosheet dispersion. Mix 1mL carbon nitride nanosheet dispersion with collagen-sodium alginate The solution was mixed (the amount of graphite phase carbon nitride nanosheets was 3% of the total mass of collagen and sodium alginate), stirred at room temperature for 2 hours, centrifuged to remove air bubbles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com