Laser-assisted calibration process for diesel engine assembly

A diesel engine and laser-assisted technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient installation of tooling, high calibration difficulty, poor stability, etc., to improve calibration quality, simplify calibration procedures, The effect of shortening the calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

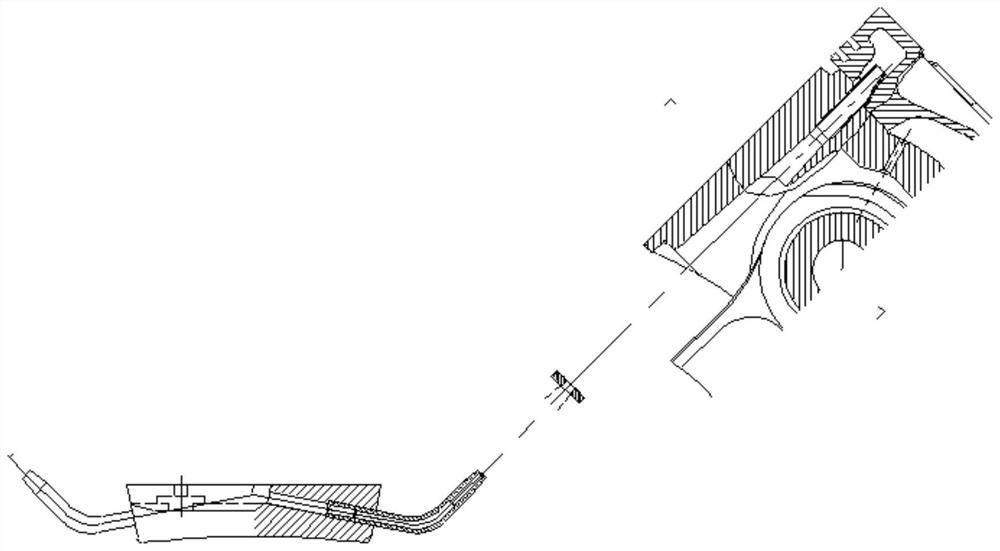

[0016] Laser-assisted alignment process for diesel engine assembly, including the following steps:

[0017] 1) Process the guide sleeve, the inner diameter of the guide sleeve matches the laser emitter, the outer diameter of the guide sleeve matches the inner diameter of the fuel injector, wherein the inner diameter of the guide sleeve and the laser emitter match in an interference fit, The outer diameter of the guide sleeve and the fuel injector are matched by an interference fit;

[0018] 2) Install the laser emitter on the guide sleeve, and connect the guide sleeve together with the laser emitter to the fuel injection nozzle. Also pluggable; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com