Fruit pitting device for food processing

A food processing and nuclear device technology, which is applied in the direction of fruit pitting devices, applications, food science, etc., can solve the problems of wasting meat, burrs and residues, and large pulp loss, and achieve the effect of improving the efficiency of pitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

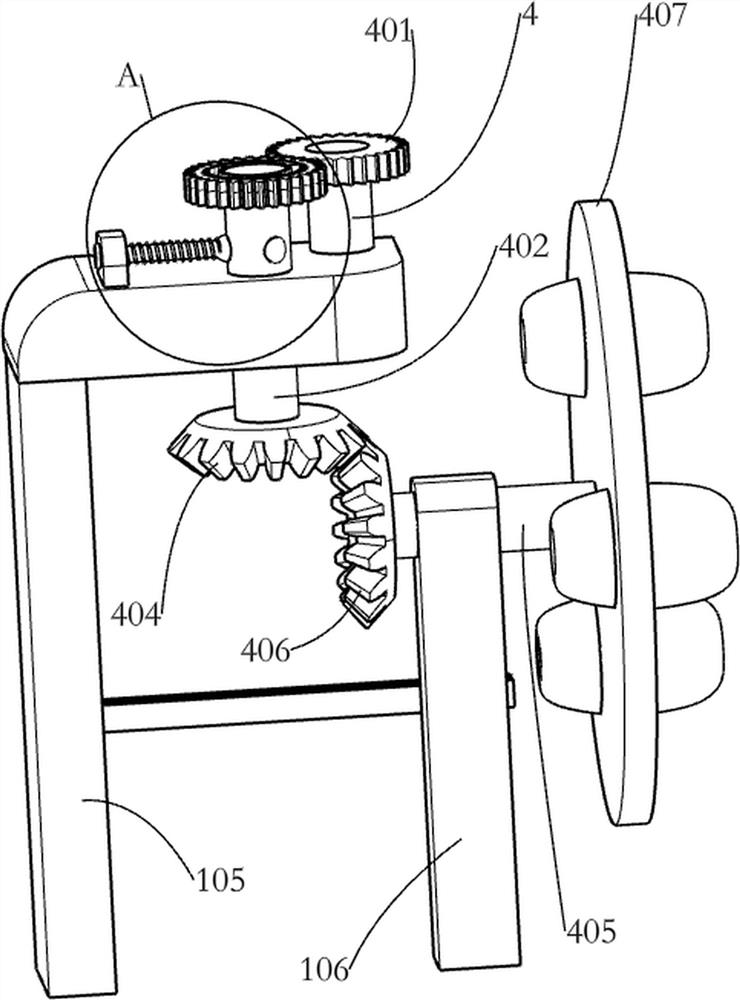

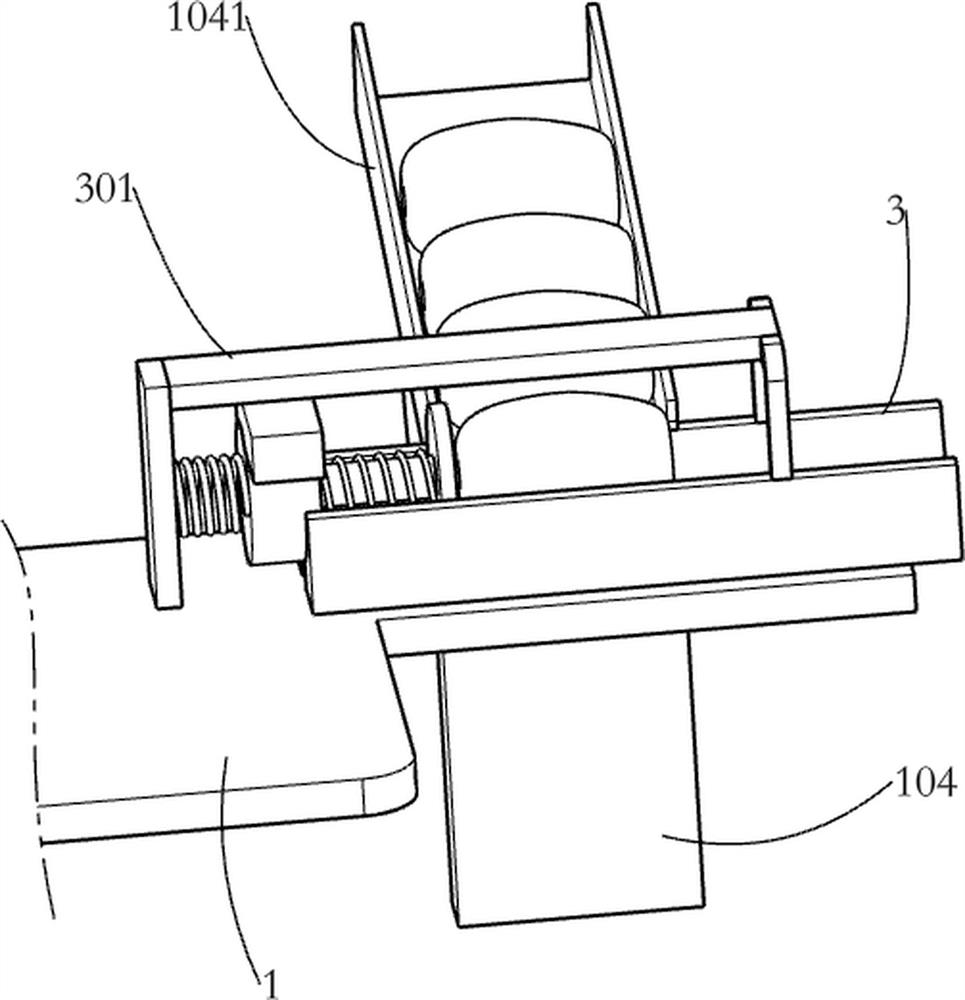

[0028] like Figure 1-2 As shown, the present invention discloses a fruit pitting device for food processing, including a base 1, a support 101, a support 2 102, a support 3 103, a support 4 104, a feeding bin 1041, a support 105, and a support 6 106 , support rod 107, electric push rod 108, support seven 1012, material box two 1013, material box one 1011, nuclear assembly and turntable assembly, base 1 upper part is fixedly installed with support one 101, support two 102, support three 103, support Four 104, support five 105, pole 107, support six 106 and support seven 1012, wherein support one 101 is located at the upper right part of base 1, support two 102 is located at the left side of support one 101, and pole 107 is located at the left side of support two 102, Support three 103 is fixedly connected with the right side of support two 102, support four 104 is located at the front side of support two 102, support five 105 is located at the front side of pole 107, support s...

Embodiment 2

[0031] combine Figure 3-5 As shown, on the basis of Embodiment 1, the core removal assembly includes a slide plate 2, a motor 109, a gear one 1091, a rack bar 201, a spur rack one 2011, a square plate two 203, a square plate one 202, a shifting block 1 204, short tube 205, gear 2 2051, push column 2052 and pre-tightening assembly, the slide plate 2 is slidably embedded in the front side of the support 2 102, the electric push rod 108 is fixedly connected to the right side of the slide plate 2, and the motor 109 is fixedly connected to the slide plate 2, the gear one 1091 is fixedly connected to the output shaft of the motor 109, the rack bar 201 is slidably connected to the bracket two 102, the rack bar 201 is fixedly connected to the slide plate 2, and the front side of the left end of the rack bar 201 is provided with a row of Teeth, the straight rack 1 2011 is fixedly connected with the right end bottom side of the rack bar 201, the square plate 1 202 and the square plate ...

Embodiment 3

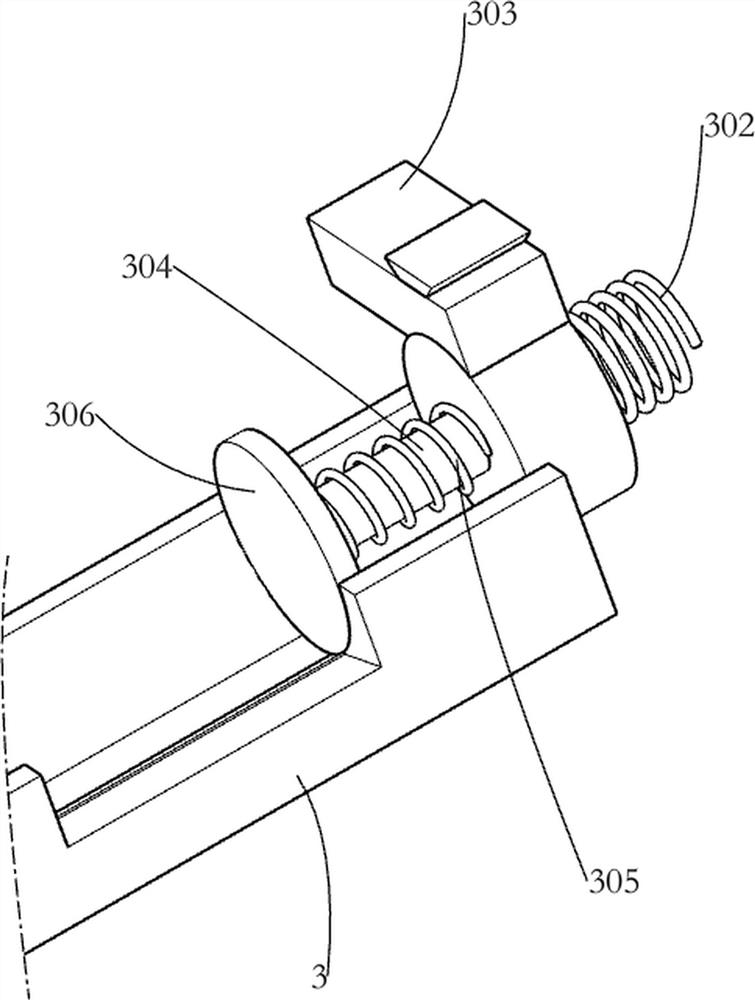

[0040] combine Figure 6-8 As shown, on the basis of Embodiment 2, a feeding assembly is also included, and the feeding assembly includes a feeding slideway 3, a supporting slide bar 301, a tension spring 302, a shifting block 2 303, a short slide bar 304, and a spring Two 305 and pusher plate 306, feeding slideway 3 is fixedly connected on the upper side of support four 104, feeding slideway 3 is in contact with feeding bin 1041, the right lower end of supporting slide bar 301 is fixedly connected with base 1, and supporting slide bar The left lower end of 301 is fixedly connected with feeding slideway 3, and shifting block two 303 is slidably connected with support slide bar 301, and shift block two 303 contacts with shift block one 204, and the right end of extension spring 302 is fixedly connected with support slide bar 301, pulls The left end of the spring 302 is fixedly connected with the shifting block 2 303, the short slide bar 304 slides through the shift block 2 303,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com