Pumpkin essence as well as preparation method and application thereof

A technology of pumpkin essence and pumpkin, which is applied in the direction of food science, etc., can solve the problems of the loss of aroma components and limit the development of pumpkin-flavored products of pumpkin products, and achieve the effect of stable aroma quality, natural and vivid flavor, and strong characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

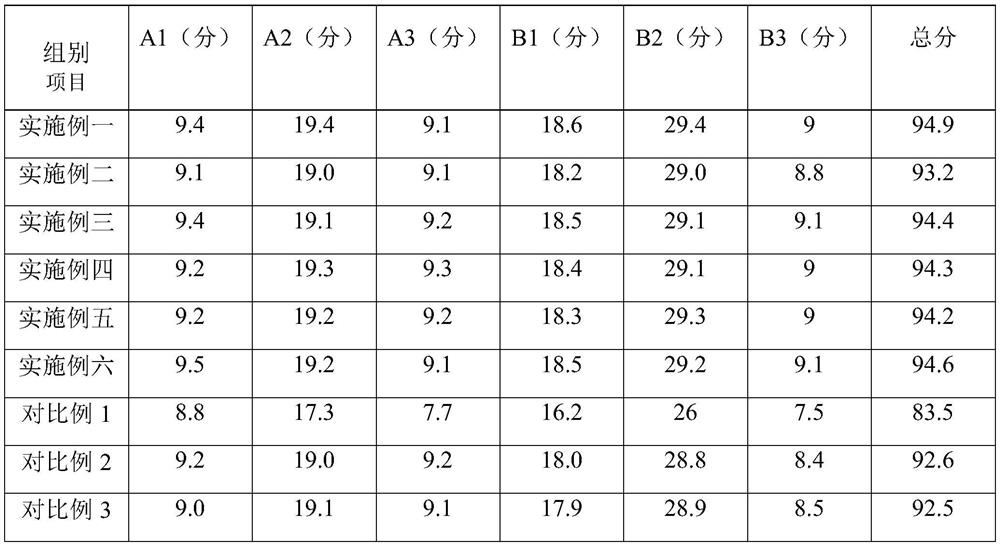

Examples

Embodiment 1

[0033] Embodiment one pumpkin essence of the present invention and preparation method thereof

[0034] Preparation materials: 0.2% hexanal, 0.04% methyl octyne carboxylate, 0.05% 3-methylthiopropanol, 0.25% β-turkone, 0.5% thiothiazole, 0.8% furanone, methylcyclopentenolone 0.1%, vanillin 1%, ethyl maltol 2.5%, propylene glycol 24.56%, pumpkin treatment liquid 70%.

[0035] The pumpkin treatment liquid is prepared by the following preparation method:

[0036] S1: adding water to the fresh and mature pumpkin pieces according to the weight ratio of pumpkin:water of 3:1;

[0037] S2: Add pectinase and cellulase, enzymatically hydrolyze the pumpkin pulp of S1 at 50°C for 0.5 hours, then raise the temperature to 90°C, keep warm for 30 minutes to inactivate the enzyme, cool and filter to obtain pumpkin enzymatic hydrolyzate.

[0038] S3: Add propylene glycol, amino acid and glucose to the enzymolysis solution to react to obtain a roasted and sweet pumpkin treatment solution; the w...

Embodiment 2

[0041] Embodiment two pumpkin essence of the present invention and preparation method thereof

[0042] Preparation materials: 0.2% hexanal, 0.02% methyl octyne carboxylate, 0.02% 3-methylthiopropanol, 0.05% β-turkone, 0.2% thiothiazole, 0.4% furanone, methylcyclopentenolone 0.05%, vanillin 0.5%, ethyl maltol 2%, propylene glycol 66.56%, pumpkin treatment liquid 30%.

[0043] The pumpkin treatment liquid is prepared by the following preparation method:

[0044] S1: adding water to the fresh and mature pumpkin pieces according to the pumpkin:water weight ratio of 1:1;

[0045] S2: Add pectinase and cellulase, enzymatically hydrolyze the pumpkin pulp of S1 at 40°C for 1 hour, then raise the temperature to 85°C, keep warm for 40 minutes to inactivate the enzyme, cool and filter to obtain pumpkin enzymatic hydrolyzate.

[0046] S3: Add propylene glycol, amino acid and glucose to the enzymolysis solution to react to obtain a roasted and sweet pumpkin treatment solution; the weight...

Embodiment 3

[0049] Embodiment three pumpkin essence of the present invention and preparation method thereof

[0050] Preparation materials: 1% hexanal, 0.2% methyl octyne carboxylate, 0.1% 3-methylthiopropanol, 0.5% β-turkone, 1% thiothiazole, 1.2% furanone, methylcyclopentenolone 0.3%, vanillin 2%, ethyl maltol 5%, propylene glycol 13.7%, pumpkin treatment liquid 75%.

[0051] The pumpkin treatment solution is prepared by the following preparation method:

[0052] S1: adding water to beating fresh and mature pumpkin pieces according to the weight ratio of pumpkin:water of 5:1;

[0053] S2: Add pectinase and cellulase, enzymolyze the pumpkin pulp of S1 at 46°C for 1 hour, then raise the temperature to 90°C, heat it for 20 minutes to inactivate the enzyme, cool and filter to obtain the pumpkin enzymatic hydrolyzate.

[0054] S3: Add propylene glycol, amino acid and glucose to the enzymolysis solution to react to obtain a roasted and sweet pumpkin treatment solution; the weight ratio of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com